ISO Standards for Plastic Products Manufacturing

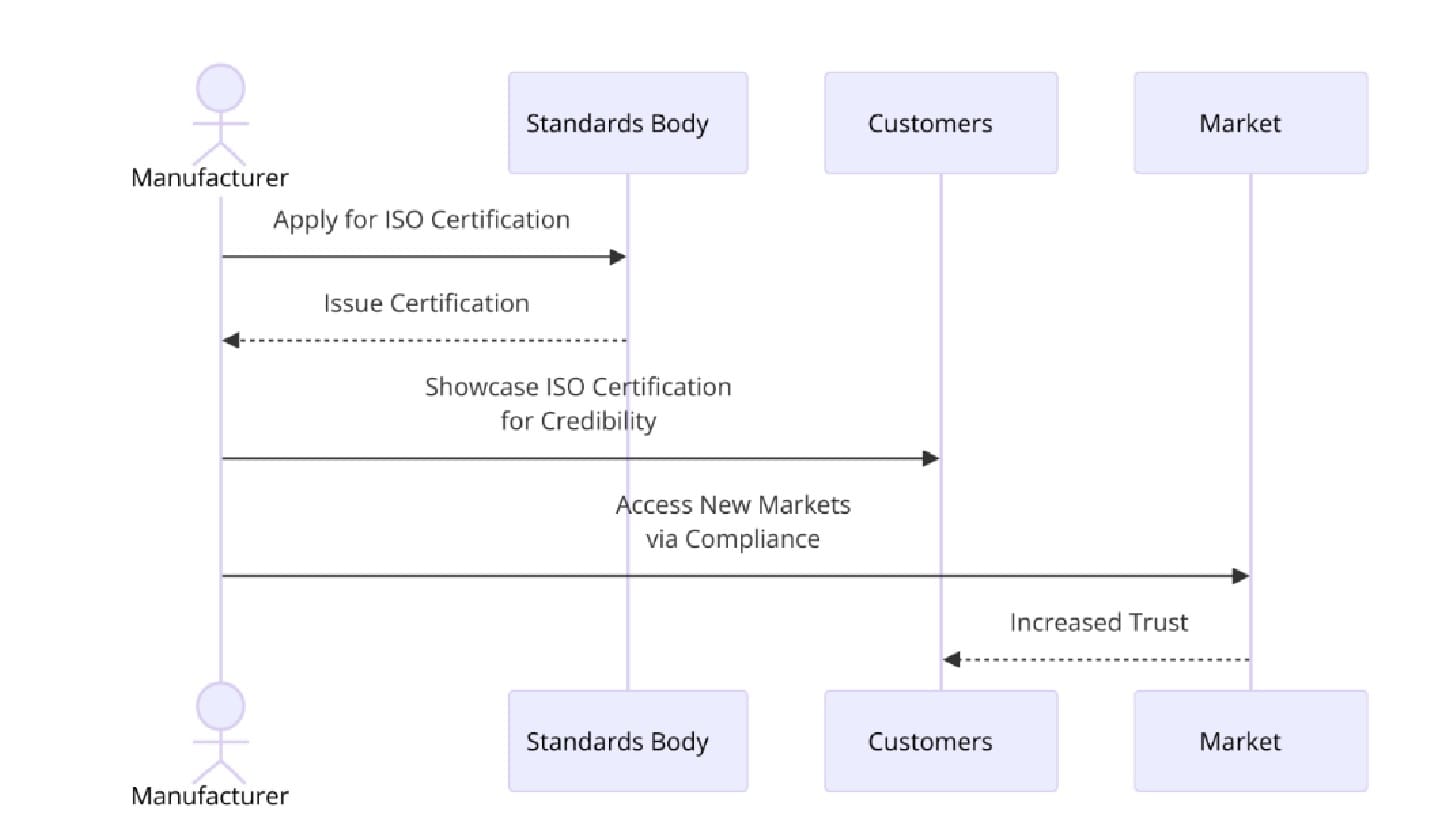

ISO certifications for plastic products manufacturing are critical in ensuring quality and environmental sustainability within the industry. As the global demand for high-quality and eco-friendly plastic products grows, manufacturers must meet internationally recognized standards to remain competitive. ISO provides a strong framework for achieving operational excellence, minimizing environmental impact and ensuring customer satisfaction.

Plastic products play an indispensable role across industries—from packaging to automotive, construction, and healthcare. By implementing ISO standards, manufacturers can ensure their products meet stringent quality and environmental benchmarks. Whether you're a large-scale operation or a smaller manufacturer, ISO certifications signal your commitment to producing reliable, sustainable, and globally acceptable products.

Reach out to our team at support@pacificcert.com for prompt and detailed responses to all your certification inquiries.

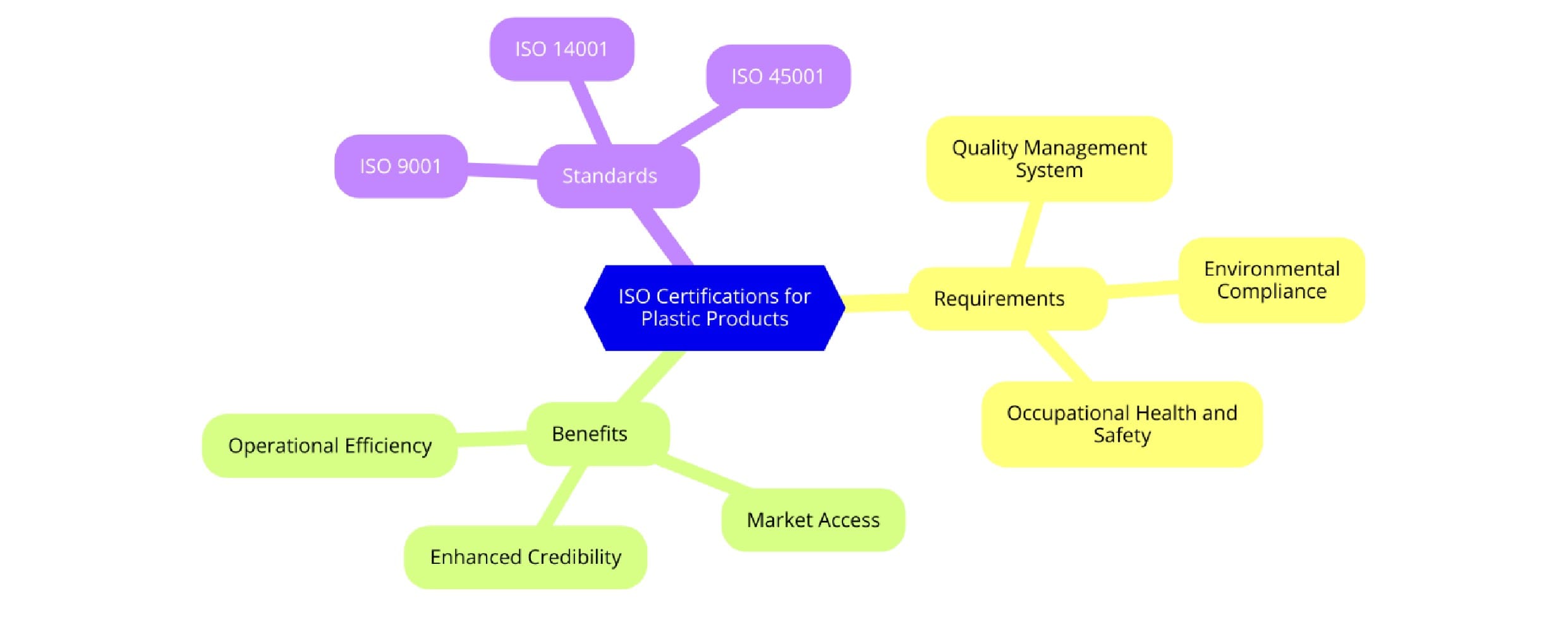

Applicable ISO Standards for Plastic Products Manufacturing

Various ISO standards apply specifically to the manufacturing of plastic products. Each of these addresses unique aspects of production, from quality management to environmental sustainability and safety practices. Below is an overview of the most relevant standards:

ISO 9001: Quality Management System (QMS)

ISO 9001 focuses on quality assurance and continuous improvement. It ensures plastic products meet customer expectations and regulatory requirements through streamlined production processes and strict quality control.

ISO 14001: Environmental Management System (EMS)

This standard helps plastic manufacturers manage environmental responsibilities, including reducing waste, emissions, and energy consumption. It is vital in addressing growing concerns about plastic pollution and promoting sustainable practices.

ISO 45001: Occupational Health and Safety Management

ISO 45001 is essential for ensuring workplace safety during plastic production. This certification mitigates risks, improves employee well-being, and fosters a safer manufacturing environment.

ISO 15378: Primary Packaging Materials for Medicinal Products

Plastic manufacturers producing packaging for pharmaceuticals must adhere to ISO 15378. It combines good manufacturing practices (GMP) with ISO 9001 principles to ensure the quality and safety of packaging materials.

ISO 26000: Social Responsibility

Though not certifiable, ISO 26000 provides guidelines for ethical and socially responsible practices, particularly important for addressing the global backlash against single-use plastics.

ISO 17025: Testing and Calibration Laboratories

Plastic manufacturers that perform in-house testing must comply with ISO 17025 to ensure laboratory accuracy and competence, a requirement for ensuring product safety and quality.

This certification encourages efficient energy use during manufacturing, reducing production costs and environmental impact—a critical factor in sustainable plastic production.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in auditing and issuing ISO certifications tailored to the unique needs of the plastic products manufacturing industry.

Our team of experienced auditors ensures your business aligns with international standards efficiently and effectively. By choosing us as your certification body, you demonstrate to customers, stakeholders, and regulators your unwavering commitment to quality, safety and sustainability.

We focus solely on impartial auditing and certification services, maintaining the highest levels of integrity. Our role is to validate your compliance, offering you the credibility and trust associated with globally recognized ISO certifications.

Email us at support@pacificcert.com to schedule a personalized discussion about your specific needs and how we can help.

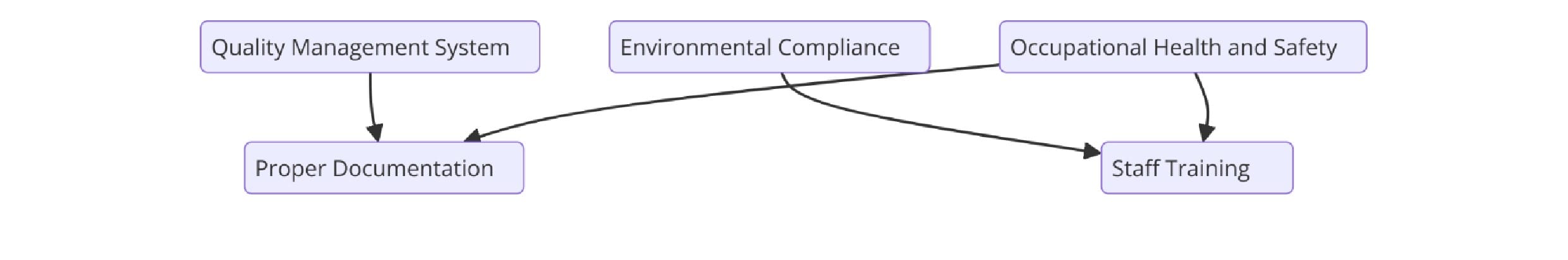

Requirements of ISO Certifications for Plastic Products Manufacturing

Complying with ISO standards involves fulfilling specific requirements, each designed to enhance different aspects of production:

ISO 9001 Requirements

- Implementation of a quality management system (QMS) aligned with customer needs.

- Regular internal audits and management reviews.

- Focus on risk-based thinking and continual improvement.

ISO 14001 Requirements

- Identifying environmental impacts and establishing control measures.

- Compliance with legal and regulatory environmental requirements.

- Ongoing evaluation and improvement of environmental performance.

ISO 45001 Requirements

- Establishing processes to identify and mitigate workplace hazards.

- Active employee participation in health and safety initiatives.

- Regular training and incident monitoring to ensure compliance.

ISO 15378 Requirements

- Adherence to GMP principles in the production of primary packaging.

- Robust documentation and traceability systems.

ISO 50001 Requirements

- Developing an energy management policy and objectives.

- Monitoring energy usage and identifying opportunities for improvement.

General Compliance Essentials

- Employee training and awareness programs.

- Systematic documentation of processes.

- Robust supplier and material selection processes.

Quick Assistance: Dial +91-8595603096 for quick and reliable guidance on starting your ISO certification journey.

Benefits of ISO Certifications for Plastic Products Manufacturing

ISO certifications offer numerous advantages to plastic product manufacturers, ensuring competitiveness and sustainability in an evolving market:

Product Quality: By adopting ISO 9001, manufacturers guarantee products that meet international quality standards, building trust and loyalty among customers.

Environmental Sustainability: ISO 14001 drives environmentally responsible manufacturing processes, reducing pollution and promoting the sustainable use of resources—a significant competitive advantage in 2024’s eco-conscious market.

Workplace Safety: ISO 45001 ensures safer work environments, reducing accidents and fostering employee satisfaction and productivity.

Market Access and Credibility: Certified manufacturers gain access to global markets, as many countries and industries require ISO compliance for suppliers.

Efficiency: Standards like ISO 50001 optimize energy usage and minimize waste, translating into reduced operational costs and higher profitability.

Customer Satisfaction and Retention: Meeting ISO standards ensures that products consistently meet or exceed customer expectations, enhancing satisfaction and retention.

In 2024, the plastic manufacturing sector is increasingly focused on sustainability and innovation. A recent market analysis reveals a surge in demand for biodegradable and recycled plastics, driven by stricter environmental regulations and consumer preferences. Companies adopting ISO certifications are better positioned to align with these trends and showcase their commitment to responsible production.

Additionally, advancements in automation and digital technologies are streamlining ISO compliance processes, making it easier for manufacturers to maintain and improve standards. By embracing these developments, certified businesses can lead the charge toward a greener, smarter, and more efficient industry.

Ready to elevate your business with ISO certifications for plastic products manufacturing? Pacific Certifications is here to support your journey toward compliance, credibility, and sustainability.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Plastic Products Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Plastic Products Manufacturing

What are the most relevant ISO certifications for plastic manufacturing?

ISO 9001, ISO 14001, ISO 45001, ISO 15378, and ISO 50001 are some of the key standards applicable to plastic product manufacturers.

How can ISO 9001 improve my plastic manufacturing business?

ISO 9001 enhances product quality, streamlines processes, and ensures customer satisfaction through a robust quality management system.

What role does ISO 14001 play in sustainability?

ISO 14001 helps manufacturers minimize environmental impact by implementing eco-friendly practices, reducing waste, and complying with environmental regulations.

Is ISO certification mandatory for plastic manufacturers?

While not always mandatory, ISO certification is highly beneficial for gaining market access, ensuring compliance, and demonstrating commitment to quality and sustainability.

How long does it take to achieve ISO certification?

The timeframe varies depending on the size and complexity of your operations, but typically it ranges from a few weeks to several months.

Why choose Pacific Certifications for ISO certification?

Pacific Certifications provides reliable and impartial auditing services, ensuring you meet ISO standards efficiently and effectively.

Read More at: Blogs by Pacific Certifications