ISO Certifications for Food Processing Machinery Manufacturing Businesses, Requirements and Benefits

Quick Summary

Manufacturers of food processing machinery face high standards for quality, safety, efficiency, and sustainability. Adopting ISO certifications provides a structured path to meet these demands. ISO 9001 ensures process reliability and customer-focused quality. ISO 14001 promotes environmental responsibility through waste and resource management. ISO 45001 safeguards both workers and end users by managing occupational hazards. ISO 22000 integrates food safety directly into machinery design and production. ISO 50001 optimizes energy use, lowering costs and environmental impact. Implementation involves setting policies, maintaining documents, conducting internal audits, and undergoing external assessments. The benefits include better product performance, boosted customer credibility, leaner operations, and stronger alignment with global sustainability and safety trends—proving invaluable in a rapidly evolving industry.

ISO certifications for Food Processing Machinery Manufacturing

The global food processing industry is at the forefront of innovation, consistently working to meet consumer demand for high-quality, safe, and environmentally friendly products. Central to this mission are ISO standards, which provide internationally recognized guidelines to ensure quality, safety, efficiency and sustainability.

ISO standards, established by the International Organization for Standardization, are essential for ensuring consistency in manufacturing processes, maintaining food safety, and meeting customer and regulatory expectations. For food processing machinery manufacturers, compliance with these standards is often a necessity.

If you're ready to elevate your Food Processing Machinery Manufacturing operations with ISO certification, contact us at [email protected] or call us at +91-8595603096 for expert guidance.

Applicable ISO Standards for Food Processing Machinery Manufacturing

ISO 9001: Quality Management Systems

ISO 9001 establishes a framework for quality management, ensuring that manufacturers meet customer and regulatory requirements. This standard emphasizes continual improvement, risk-based thinking, and customer satisfaction.

ISO 14001: Environmental Management Systems

Environmental sustainability is a growing concern. ISO 14001 helps organizations manage their environmental responsibilities effectively, reducing waste and improving resource efficiency.

ISO 45001: Occupational Health and Safety

ISO 45001 focuses on creating safe workplaces. For machinery manufacturers, it ensures that both employees and users of their equipment are protected from potential hazards.

ISO 22000: Food Safety Management Systems

Food safety is paramount in this sector. ISO 22000 integrates food safety management into the manufacturing process, ensuring that equipment complies with hygiene standards.

ISO 50001: Energy Management Systems

Energy efficiency is a critical component of sustainable manufacturing. ISO 50001 guides organizations in optimizing energy use, reducing costs, and minimizing their carbon footprint.

Click here to find out more applicable standards to your industry

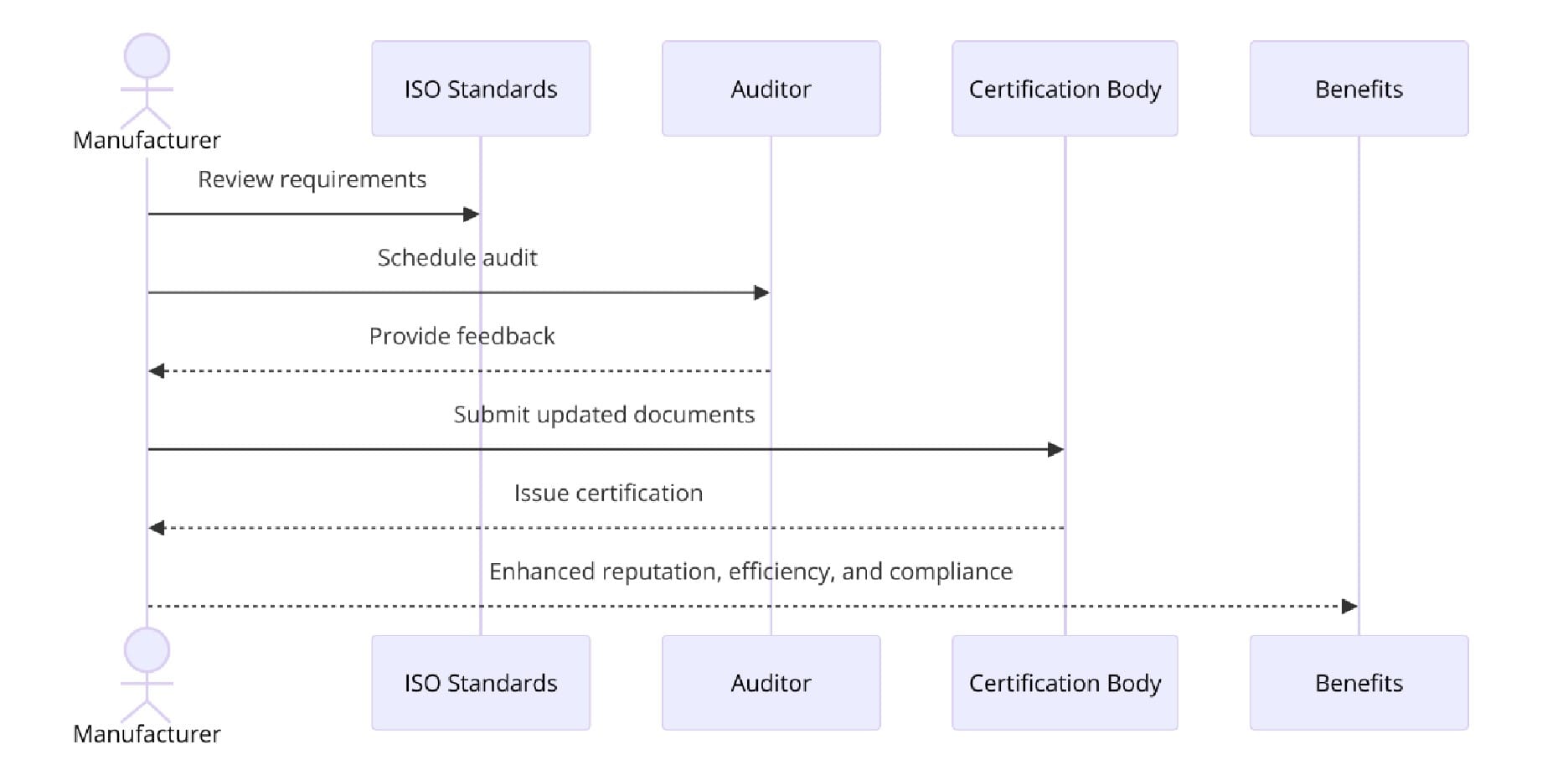

At Pacific Certifications, we specialize in auditing and certifying businesses across various ISO standards. With our expertise, we ensure that your organization complies with all relevant standards, paving the way for improved operational efficiency, market access, and customer trust.

Take the first step towards ISO compliance for Food Processing Machinery Manufacturing by contacting us at [email protected] or dialing +91-8595603096 today.

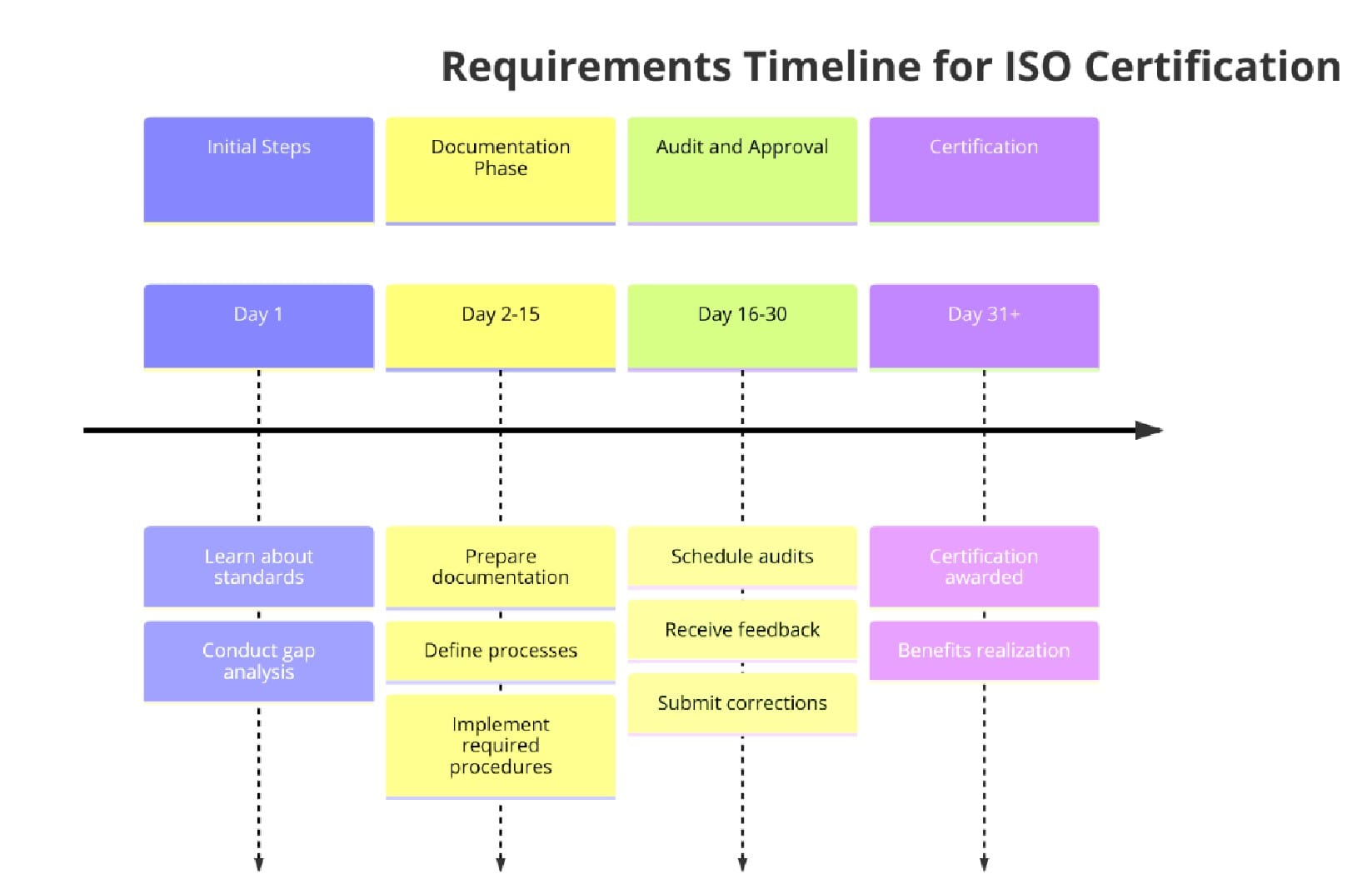

Requirements of ISO Certifications for Food Processing Machinery Manufacturing

Here are the specific requirements for each applicable ISO standard in the food processing machinery manufacturing industry:

ISO 9001: Quality Management Systems (QMS) Requirements

Quality Policy and Objectives:

- Develop and communicate a clear quality policy aligned with organizational goals.

- Establish measurable quality objectives.

Documentation Requirements:

- Maintain a quality manual, documented procedures, and records.

- Establish a robust document control system.

Process Approach:

- Identify, manage, and continually improve key processes within the organization.

Risk-Based Thinking:

- Assess risks and opportunities associated with processes and products.

Customer Focus:

- Ensure customer requirements are met or exceeded.

Performance Evaluation:

- Conduct regular internal audits, management reviews, and performance evaluations.

ISO 14001: Environmental Management Systems (EMS) Requirements

Environmental Policy:

- Develop an environmental policy reflecting the organization’s commitment to sustainability.

Environmental Aspects:

- Identify and evaluate the environmental aspects and impacts of operations.

Legal and Other Requirements:

- Ensure compliance with applicable environmental laws and regulations.

Operational Controls:

- Implement controls to manage significant environmental aspects.

Emergency Preparedness:

- Establish procedures for handling potential environmental emergencies.

Monitoring and Measurement:

- Regularly monitor environmental performance and maintain records.

ISO 45001: Occupational Health and Safety (OH&S) Requirements

Health and Safety Policy:

- Develop and implement an OH&S policy that prioritizes workplace safety.

Hazard Identification:

- Identify and assess workplace hazards to prevent incidents.

Employee Participation:

- Involve employees and stakeholders in the OH&S management system.

Compliance with Legal Requirements:

- Adhere to occupational health and safety laws and standards.

Emergency Preparedness and Response:

- Establish and regularly test emergency procedures.

Performance Monitoring:

- Track safety metrics and continuously improve the OH&S management system.

ISO 22000: Food Safety Management Systems (FSMS) Requirements

Food Safety Policy:

- Establish a clear commitment to food safety across all levels of the organization.

Hazard Analysis and Critical Control Points (HACCP):

- Conduct a hazard analysis and implement critical control points.

Prerequisite Programs (PRPs):

- Develop PRPs to maintain hygiene and operational conditions.

Traceability System:

- Implement systems to trace products through the supply chain.

Communication:

- Maintain effective communication with stakeholders about food safety concerns.

Internal Audits:

- Regularly audit the FSMS to ensure effectiveness.

ISO 50001: Energy Management Systems (EnMS) Requirements

Energy Policy:

- Define and communicate an energy management policy.

Energy Review:

- Conduct an energy review to identify significant energy uses and opportunities for improvement.

Energy Objectives and Targets:

- Set measurable energy performance objectives and targets.

Energy Baseline:

- Establish a baseline to measure energy performance improvements.

Operational Controls:

- Optimize operations to enhance energy efficiency.

Monitoring and Measurement:

- Continuously monitor energy use and implement corrective actions where necessary.

These requirements form the backbone of compliance for food processing machinery manufacturing companies seeking ISO certification. Meeting these standards enhances operational efficiency and also builds trust with customers and stakeholders.

We are here to help you achieve ISO certification for Food Processing Machinery Manufacturing. Contact us at [email protected] or call +91-8595603096 for more information!

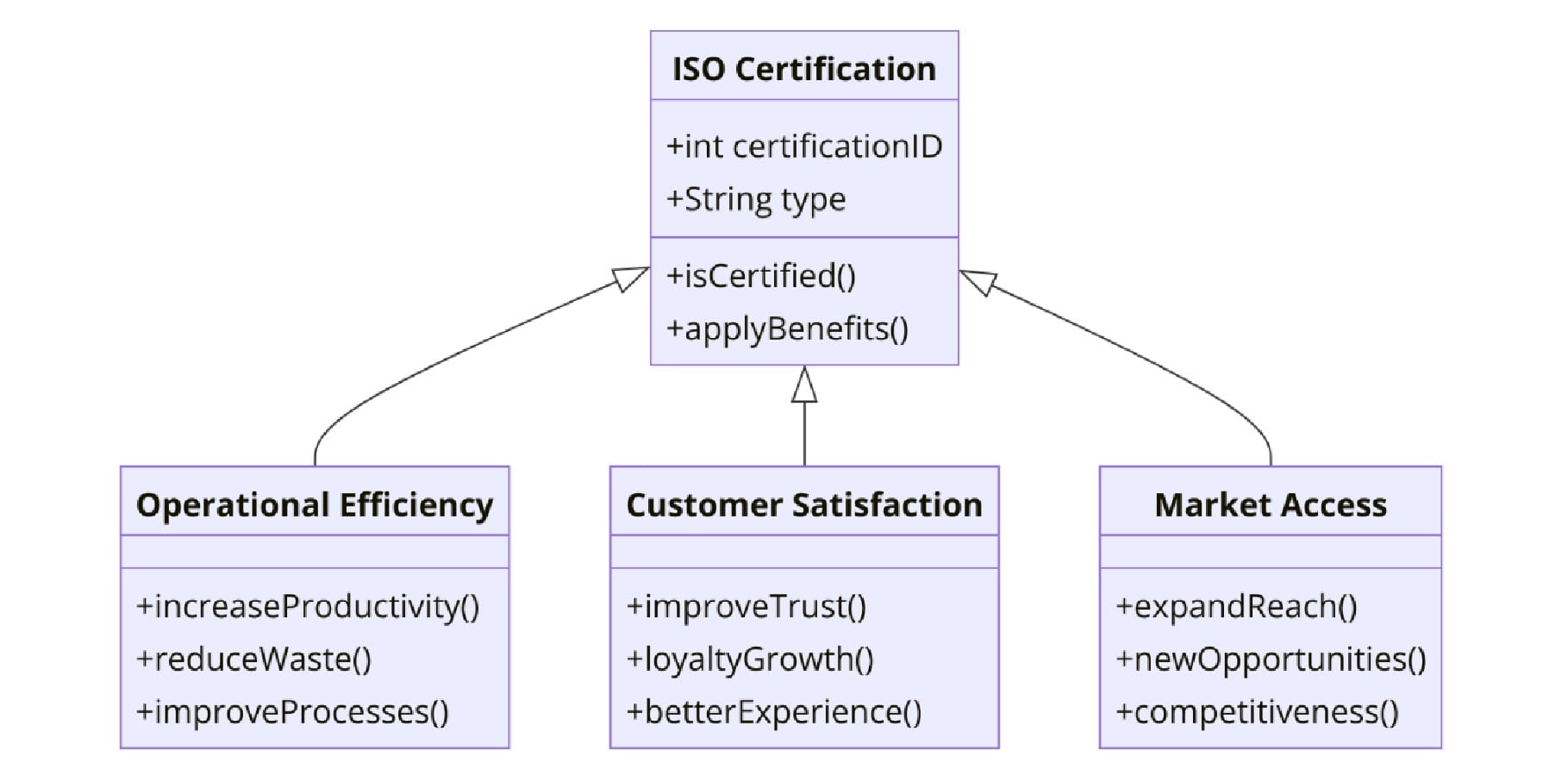

Benefits of ISO Certifications for Food Processing Machinery Manufacturing

Product Quality: Adopting ISO standards ensures that your machinery meets stringent quality criteria, resulting in reliable and efficient products.

Customer Trust and Satisfaction: ISO certifications are a mark of credibility, signaling to customers that your products and processes meet international standards.

Processes and Cost Efficiency: By standardizing operations and improving resource management, manufacturers can reduce costs and increase profitability.

Sustainability: Compliance with environmental and safety standards helps companies contribute to global sustainability goals and avoid regulatory penalties.

In this year, the food processing machinery industry is poised for significant growth, driven by technological innovations, increased focus on sustainability, and stringent regulatory requirements.

Companies adopting ISO standards are better positioned to capitalize on these trends, achieving operational excellence. Contact us to begin your certification process!

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Food Processing Machinery Manufacturing business, please contact us at [email protected] or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs