ISO Certifications for Prefabricated Wooden Building Manufacturing Businesses, Requirements and Benefits

ISO Standards for Prefabricated Wooden Building Manufacturing

ISO certifications play a pivotal role in ensuring that prefabricated wooden building manufacturers adhere to international standards of quality and safety. With increasing global demand for sustainable construction, obtaining ISO certifications has become a benchmark for manufacturers striving to gain trust and market competitiveness.

This article explores the relevant ISO standards, their requirements, and the benefits they bring to prefabricated wooden building manufacturers.

Prefabricated wooden buildings have revolutionized the construction industry by offering sustainable, cost-effective, and efficient solutions. These structures, crafted off-site and assembled on location, have gained significant traction worldwide.

To meet global quality and sustainability benchmarks, manufacturers must align their practices with International Organization for Standardization (ISO) standards.

ISO certifications provide a framework that ensures operational excellence, environmental stewardship, and safety in manufacturing. By obtaining these certifications, manufacturers demonstrate their commitment to delivering superior products that meet both regulatory and customer expectations.

Applicable ISO Standards for Prefabricated Wooden Building Manufacturing

Various ISO standards cater specifically to the prefabricated wooden building industry, addressing critical aspects such as quality management, environmental impact, and occupational health. Below are the key standards:

ISO 9001: Quality Management System (QMS)

ISO 9001 focuses on ensuring that manufacturers establish processes to consistently deliver high-quality prefabricated wooden buildings. This standard encompasses customer satisfaction, risk management, and continual improvement.

ISO 14001: Environmental Management System (EMS)

Environmental sustainability is paramount in prefabricated construction. ISO 14001 helps manufacturers reduce their environmental footprint through efficient resource utilization, waste management, and compliance with environmental regulations.

ISO 45001: Occupational Health and Safety Management System

Safety is critical in the manufacturing of prefabricated wooden buildings. ISO 45001 ensures a safe working environment by minimizing risks and implementing effective safety protocols.

ISO 26000: Social Responsibility

Although not certifiable, ISO 26000 provides guidance on implementing socially responsible practices. Prefabricated wooden building manufacturers can use this standard to align their operations with ethical and sustainable principles.

ISO 50001: Energy Management

Energy efficiency is a key concern in manufacturing. ISO 50001 helps companies optimize their energy usage, reducing operational costs and environmental impact.

ISO 20887: Sustainability in Building Construction

This standard specifically addresses the design for disassembly and adaptability of prefabricated buildings, ensuring that structures are sustainable throughout their lifecycle.

ISO 21930: Environmental Declaration of Building Products

ISO 21930 supports transparency by enabling manufacturers to provide environmental product declarations (EPDs), highlighting the sustainability of their materials and processes.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in auditing and certifying organizations in compliance with ISO standards. Our team provides expert certification services tailored to the prefabricated wooden building industry. With a focus on precision and integrity, we help manufacturers achieve ISO certifications, enabling them to thrive in competitive markets.

Need ISO certification for your prefabricated wooden building manufacturing? Contact [email protected] or call us at +91-8595603096 for reliable and professional service.

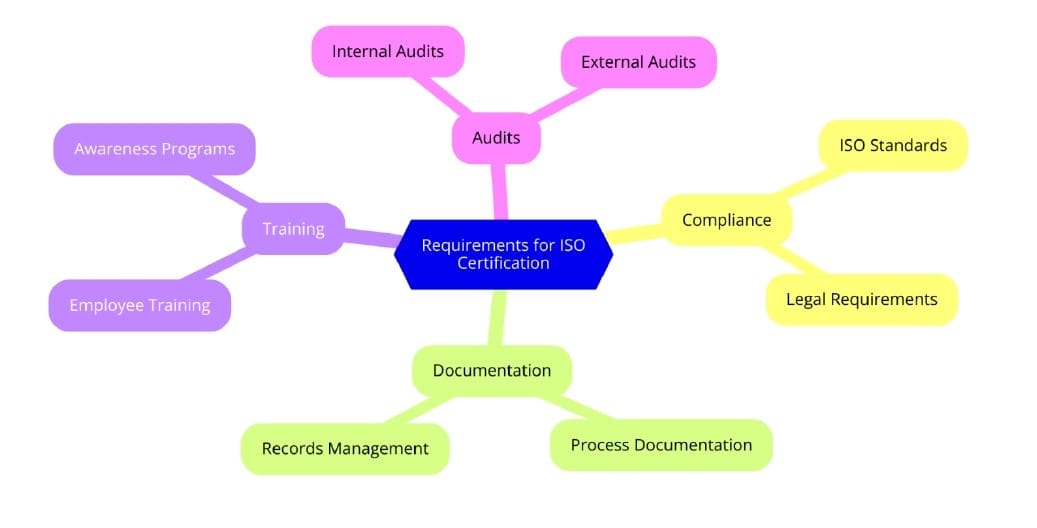

Requirements of ISO Certifications for Prefabricated Wooden Building Manufacturing

ISO certifications each come with a unique set of requirements designed to address specific operational aspects of prefabricated wooden building manufacturing. Below is a breakdown of the essential requirements for the most applicable ISO standards in the industry:

ISO 9001: Quality Management System (QMS) requirements

- Process Orientation: Define, document, and standardize processes to ensure consistency in manufacturing.

- Customer Focus: Understand customer needs and expectations and strive for customer satisfaction.

- Leadership Commitment: Leadership must actively support and engage in quality management practices.

- Risk-Based Thinking: Identify potential risks and opportunities that could impact quality.

- Continuous Improvement: Implement corrective actions and regularly evaluate processes to enhance performance.

- Document Control: Maintain clear and accessible records of all quality management processes.

ISO 14001: Environmental Management System (EMS) requirements

- Environmental Policy: Develop a policy outlining the company’s commitment to environmental protection.

- Identification of Environmental Aspects: Assess the environmental impact of materials, processes, and operations.

- Legal Compliance: Ensure adherence to applicable environmental laws and regulations.

- Resource Management: Optimize the use of natural resources, minimize waste, and adopt recycling practices.

- Monitoring and Measurement: Track environmental performance through established metrics.

- Continual Improvement: Set and achieve objectives to enhance environmental sustainability.

ISO 45001: Occupational Health and Safety Management System requirements

- Hazard Identification: Identify potential hazards in the workplace, especially those specific to wooden building manufacturing.

- Risk Assessment: Evaluate risks and determine appropriate mitigation measures.

- Legal and Regulatory Compliance: Ensure conformity with occupational health and safety laws.

- Worker Participation: Engage employees in safety practices and training.

- Incident Reporting and Investigation: Develop protocols for reporting, investigating, and addressing workplace incidents.

- Emergency Preparedness: Establish plans and procedures for emergency situations.

ISO 50001: Energy Management System requirements

- Energy Policy: Commit to improving energy performance through an organizational energy policy.

- Energy Baseline: Establish a baseline to measure current energy usage.

- Energy Review: Conduct a thorough assessment of energy usage and identify areas for improvement.

- Performance Indicators: Define key energy performance indicators (EnPIs) for tracking efficiency.

- Action Plan: Create action plans with specific energy-saving targets and initiatives.

- Monitoring and Verification: Use tools to monitor energy performance and validate improvements.

ISO 20887: Sustainability in Building Construction requirements

- Lifecycle Assessment: Design prefabricated buildings for a sustainable lifecycle, focusing on adaptability and disassembly.

- Material Selection: Use sustainable and recyclable materials where possible.

- Waste Minimization: Incorporate strategies to reduce construction and demolition waste.

- Energy Efficiency: Design buildings to optimize energy use during their operational phase.

- Sustainability Metrics: Establish and track measurable sustainability goals.

ISO 21930: Environmental Declaration of Building Products requirements

- Environmental Product Declarations (EPDs): Prepare standardized declarations that disclose environmental data about building materials.

- Life Cycle Inventory Analysis: Evaluate the environmental impact of materials from extraction to end-of-life.

- Data Transparency: Ensure transparency and accuracy in reporting environmental impacts.

- Conformance to Standards: Align EPDs with global sustainability and building standards.

ISO 26000: Social Responsibility (Guidance Standard) requirements

- Stakeholder Engagement: Identify and engage stakeholders to address social and ethical concerns.

- Ethical Conduct: Demonstrate ethical behavior in all aspects of business operations.

- Sustainability Integration: Incorporate sustainable development into business strategies.

- Transparency: Maintain openness about organizational impacts on society and the environment.

How These Requirements Translate to Prefabricated Wooden Building Manufacturing?

Each of these standards contributes to a robust, sustainable, and safety-focused operational framework. Meeting these requirements enables prefabricated wooden building manufacturers to ensure:

- Product quality and consistency (ISO 9001).

- Reduced environmental footprint (ISO 14001).

- Safe work environments (ISO 45001).

- Energy-efficient operations (ISO 50001).

- Sustainable lifecycle practices (ISO 20887 and ISO 21930).

Compliance with these requirements not only enhances operational efficiency but also aligns businesses with global market trends and customer expectations.

ISO certification validates your commitment to excellence. Let us help you. Email [email protected] or phone +91-8595603096 for more details.

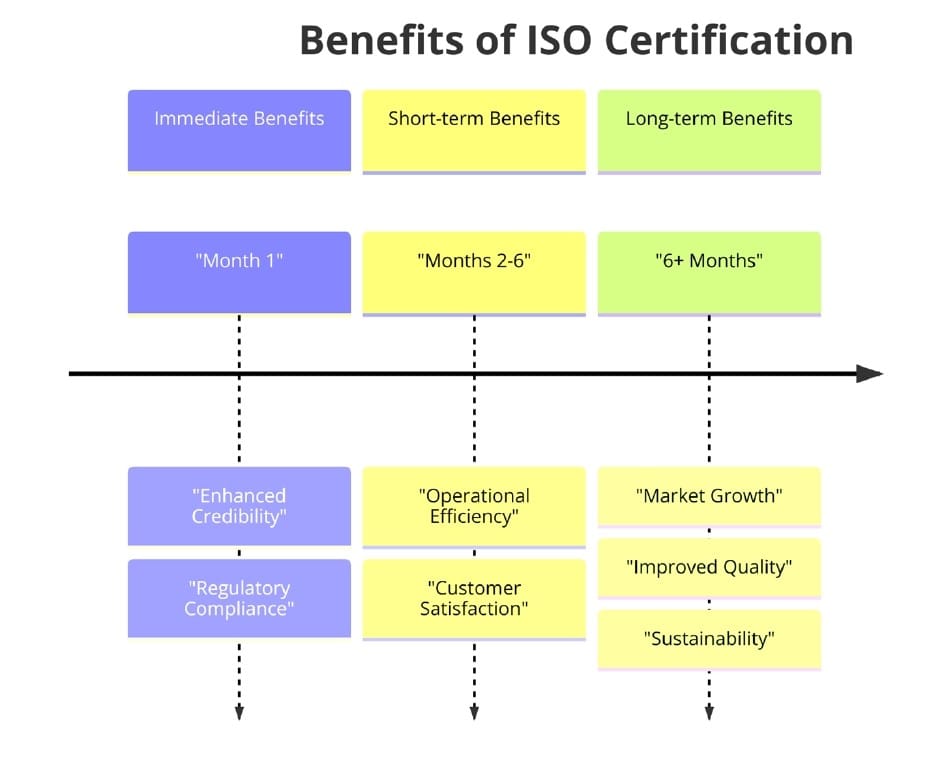

Benefits of ISO Certifications for Prefabricated Wooden Building Manufacturing

Adhering to ISO standards offers numerous advantages for manufacturers, ranging from operational efficiency to enhanced customer trust. Here are some key benefits:

Product Quality: ISO standards ensure that prefabricated wooden buildings meet high-quality benchmarks, fostering customer satisfaction and repeat business.

Environmental Responsibility: Standards like ISO 14001 and ISO 50001 support sustainable manufacturing practices, enabling companies to align with global environmental goals.

Safety and Employee Morale: ISO 45001 implementation results in a safer workplace, boosting employee morale and productivity while reducing incidents.

Market Competitiveness: ISO-certified manufacturers enjoy a competitive edge, as certifications are often prerequisites for entering certain markets or winning large contracts.

Cost Savings: By optimizing processes and reducing waste, ISO certifications contribute to significant cost savings over time.

Global Recognition: ISO certifications are globally recognized, opening doors to international markets and partnerships.

Customer Trust and Credibility: ISO certifications signal to customers that the manufacturer adheres to the highest standards of quality, safety, and sustainability.

Conclusion

The prefabricated wooden building industry is poised for significant growth in 2024, driven by an increasing demand for sustainable construction solutions. According to market research, the global market for prefabricated buildings is projected to reach unprecedented heights, with wooden structures at the forefront due to their eco-friendly attributes.

ISO certifications will remain a critical factor for manufacturers aiming to establish themselves as leaders in this burgeoning market.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Prefabricated Wooden Building Manufacturing business, please contact us at [email protected] or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs