ISO Certifications for Plastic Bag and Film Manufacturing Businesses, Requirements and Benefits

Introduction

Plastic bag and film manufacturing remains a key part of global packaging, used across food, agriculture, healthcare, and retail sectors. Despite growing concern over plastic waste, the demand for flexible packaging continues to rise because of its convenience, durability, and cost-effectiveness. However, manufacturers now face increasing pressure to reduce environmental impact, comply with stricter regulations, and maintain consistent product quality.

According to market research, the global plastic film and bag market exceeded USD 130 billion in 2024 and is expected to continue growing at around 4–5% CAGR through 2030, largely driven by food packaging and agricultural applications. At the same time, policies limiting single-use plastics and encouraging recycling are reshaping how manufacturers operate. For these businesses, ISO certifications provide a structured and credible way to meet legal, environmental, and customer expectations.

As the world moves toward sustainable packaging, ISO certifications help plastic manufacturers prove they can produce responsibly, safely, and with consistent quality - Pacific Certifications

If you’re aiming for ISO certification for plastic bag and film manufacturing, reach out to us at[email protected] or call +91-8595603096.

Quick Summary

ISO certifications help plastic bag and film manufacturers produce high-quality, safe, and environmentally responsible products. Key standards include ISO 9001 (quality), ISO 14001 (environment), and ISO 45001 (safety), with ISO 15270 guiding recycling and sustainability efforts. Certification improves efficiency, reduces waste, and helps companies meet market and regulatory expectations in a fast-changing industry.

Applicable ISO Standards for Plastic Bag and Film Manufacturing

ISO standards play a vital role in helping manufacturers meet global benchmarks. Here are some key ISO certifications relevant to plastic bag and film production:

ISO 9001: Quality ManagementSystem (QMS)

ISO 9001 focuses on consistent product quality and customer satisfaction. It ensures manufacturers adopt robust quality management systems, enabling better process efficiency and reduced defects.

ISO 14001: Environmental Management System (EMS)

With increasing concerns about plastic waste, ISO 14001 is critical for addressing the environmental impact of production processes. It helps businesses minimize waste, optimize resource use, and comply with environmental regulations.

ISO 45001: Occupational Health and Safety (OHS)

This standard safeguards employees by establishing safe and healthy workplace practices. It is particularly relevant for manufacturers dealing with potentially hazardous materials or machinery.

ISO 22000: Food Safety Management Systems

For manufacturers producing plastic films or bags for food packaging, ISO 22000 ensures compliance with food safety standards and regulations.

ISO 50001: Energy Management Systems

Energy-intensive processes in plastic manufacturing can benefit from ISO 50001. It helps organizations improve energy efficiency, reduce costs, and lower carbon footprints.

ISO 13485: Medical Device Quality Management

For manufacturers creating plastic films or bags for medical applications, ISO 13485 ensures adherence to quality and safety standards specific to healthcare requirements.

ISO 11469: Plastics Identification and Marking

This specific standard provides guidelines for the labeling and identification of plastic products, essential for promoting recycling and sustainable disposal.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in providing audit and certification services for ISO standards across industries, including plastic bag and film manufacturing. By partnering with us, businesses benefit from a seamless certification process guided by experienced auditors.

Let Pacific Certifications simplify your ISO certification journey. Email us at [email protected].

What are the requirements of ISO Certifications for Plastic Bag and Film Manufacturing?

Below is a detailed breakdown of the key requirements for each ISO standard applicable to plastic bag and film manufacturing.

General requirements:

Defining scope: Identifying product types (e.g., polyethylene films, compostable bags, industrial liners) and production processes.

Policies and objectives: Establishing clear commitments to quality, safety, and environmental performance.

Risk assessment: Evaluating risks such as machinery breakdown, contamination, energy waste, and plastic leakage.

Process control: Standardizing raw material selection, extrusion, printing, lamination, and packaging stages.

Waste management: Implementing recycling, regrind systems, and segregation of production waste.

Training: Ensuring workers are trained in machine handling, quality checks, and safety procedures.

Monitoring performance: Tracking defect rates, energy use, emissions, and customer complaints.

Documentation and audits: Maintaining procedures, inspection records, and internal audit results

Specific requirements:

ISO 9001: Quality Management System (QMS) Requirements

Quality Policy and Objectives: Develop and document a clear quality policy and measurable objectives aligned with customer expectations and regulatory compliance.

Process Approach: Identify, document, and manage all processes within the organization to ensure consistent product quality.

Customer Focus: Ensure that customer requirements are understood, met, and exceeded where possible.

Leadership Commitment: Top management must demonstrate leadership and commitment to the implementation and maintenance of the QMS.

Risk Management: Identify risks and opportunities that could impact product quality and address them effectively.

Continuous Improvement: Implement mechanisms for regularly reviewing and improving quality processes and performance.

ISO 14001: Environmental Management System (EMS) Requirements

Environmental Policy: Develop a policy that commits to environmental protection, compliance with legal requirements, and continual improvement.

Environmental Aspects Identification: Identify activities, products, or services that interact with the environment and evaluate their impact.

Compliance Obligations: Identify and adhere to applicable environmental laws and regulations.

Environmental Objectives and Planning: Set measurable objectives to improve environmental performance and create action plans to achieve them.

Operational Control: Establish procedures to manage significant environmental aspects effectively.

Monitoring and Evaluation: Regularly monitor environmental performance and ensure timely reporting of data.

ISO 45001: Occupational Health and Safety (OHS) Requirements

Hazard Identification and Risk Assessment: Identify workplace hazards and assess risks to employees' health and safety.

Legal and Other Requirements: Comply with relevant health and safety regulations applicable to the manufacturing industry.

Health and Safety Policy: Formulate and communicate a policy focused on employee well-being and workplace safety.

Employee Participation: Engage employees at all levels in identifying risks and developing solutions for a safer workplace.

Incident Reporting and Investigation: Establish procedures for reporting, investigating, and resolving workplace incidents.

Emergency Preparedness: Develop and test plans to respond to emergencies such as chemical spills or equipment failures.

ISO 22000: Food Safety Management Systems (for food packaging materials) Requirements

Hazard Analysis and Critical Control Points (HACCP): Implement a systematic approach to identify and control potential hazards in food packaging processes.

Food Safety Policy: Develop a policy that commits to food safety and regulatory compliance.

Traceability System: Ensure the ability to trace the entire supply chain to guarantee product safety and recall capability.

Prerequisite Programs (PRPs): Establish basic conditions such as hygiene and sanitation to ensure a safe manufacturing environment.

Validation and Verification: Regularly test and validate food safety processes to ensure compliance.

Internal Audits: Conduct routine audits to evaluate the effectiveness of the food safety management system.

ISO 50001: Energy Management Systems (EnMS) Requirements

Energy Policy: Create a policy outlining the organization’s commitment to improving energy performance.

Energy Planning: Conduct an energy review to identify significant energy uses and areas for improvement.

Performance Indicators (EnPIs): Establish metrics to measure energy performance and track progress.

Energy Objectives and Targets: Define measurable energy efficiency objectives and develop action plans to achieve them.

Operational Control: Implement procedures to control energy-intensive processes and equipment.

Monitoring and Measurement: Continuously monitor energy consumption and evaluate improvements against baseline data.

ISO 13485: Medical Device Quality Management (for medical applications) Requirements

Documentation Requirements: Maintain detailed records for all processes, including design, production, and testing of medical-grade plastic products.

Risk Management: Identify and control risks associated with medical devices and components throughout their lifecycle.

Product Traceability: Ensure comprehensive tracking of raw materials, components, and finished products.

Design and Development Controls: Follow strict controls to ensure medical products meet performance and safety requirements.

Validation and Testing: Perform rigorous testing and validation of manufacturing processes and products.

Post-Market Surveillance: Monitor products after release to ensure continued compliance with safety and quality standards.

ISO 11469: Plastics Identification and Marking Requirements

Product Labeling: Ensure all plastic bags and films are marked with appropriate recycling symbols or identification codes.

Material Compliance: Use materials that conform to specific standards for recyclability or biodegradability, where applicable.

Sustainability Practices: Promote responsible disposal and recycling through clear identification marks.

Documentation: Maintain accurate records of material specifications for traceability and compliance.

Tip: Start with ISO 9001 to create the foundation for quality control, then add ISO 14001 to address environmental impact. If products are used in food packaging, ensure compliance with ISO 22000 or HACCP for hygiene and safety.

Ensure your plastic bag and film manufacturing processes meet international standards. Contact us at [email protected].

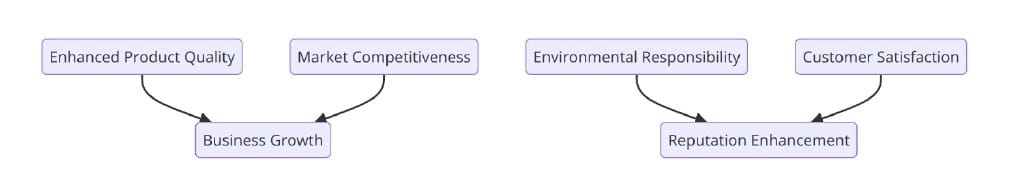

What are the benefits of ISO Certifications for Plastic Bag and Film Manufacturing?

Adopting ISO standards offers numerous advantages for manufacturers, helping them stay competitive and compliant, below are the key benefits:

Consistent product quality: ISO 9001 reduces rejection rates and strengthens client confidence.

Compliance: ISO 14001 supports waste reduction, recycling, and legal compliance on emissions and disposal.

Safety: ISO 45001 helps lower accident rates and ensures proper use of protective equipment.

Efficiency: ISO 50001 improves energy use in extrusion, heating, and cooling systems.

Market access: Certification is often required by large retailers and food producers for supplier approval.

Brand reputation: ISO-certified manufacturers are viewed as responsible and reliable partners.

Sustainability: ISO 15270 promotes circular economy practices through recovery and reuse of plastics.

The global transition toward eco-friendly packaging is reshaping the plastic industry. Many countries, including several in Africa and Asia, have introduced restrictions on single-use plastics, leading to innovation in biodegradable and recyclable film materials.

According to the United Nations Environment Programme (UNEP), more than 180 nations have policies in place to reduce plastic pollution, prompting manufacturers to adopt standards like ISO 14001 and ISO 15270. Companies investing in recycling plants, energy efficiency, and bio-based materials are finding it easier to secure partnerships with international buyers.

Automation and quality monitoring systems are also becoming common, helping producers align with ISO 9001’s continuous improvement principles. As consumer demand shifts toward sustainability, ISO-certified facilities are better positioned to prove compliance, traceability, and accountability throughout their supply chains.

How Pacific Certifications Can Help?

Pacific Certifications, accredited by ABIS, provides independent auditing and certification services for plastic bag and film manufacturers. We certify management systems such as ISO 9001, ISO 14001, ISO 45001, ISO 50001, and ISO 22000, ensuring full compliance with international standards.

We also offer accredited Lead Auditor and Implementer training programs under ISO/IEC 17024 for professionals managing quality, environment, and safety systems.

Our certification process is impartial, transparent, and recognized globally, helping manufacturers build credibility with clients, meet environmental obligations, and prepare for export opportunities.

If you need support with ISO certification for your Plastic Bag and Film Manufacturing business, contact us at [email protected] or +91-8595603096.

Contact Us

If you need support with ISO certifications for Plastic Bag and Film Manufacturing Businesses, contact us at [email protected].

Author: Pooja

Read More at: Blogs by Pacific Certifications