ISO Certifications for Paperboard Manufacturing Businesses, Requirements and Benefits

ISO Standards for Paperboard Manufacturing

The paperboard manufacturing industry plays a pivotal role in packaging, sustainability & innovation. With global demand increasing, implementing quality and environmental standards has become non-negotiable. ISO certifications for paperboard manufacturing are essential tools for ensuring product excellence and sustainability while keeping up with market dynamics.

ISO (International Organization for Standardization) sets globally recognized benchmarks for quality, safety and efficiency. In the paperboard manufacturing sector, ISO certifications ensure that manufacturers meet stringent requirements across production and product reliability.

For paperboard manufacturers, the challenge lies not only in maintaining efficiency but also in balancing environmental concerns, customer demands, and regulatory compliance. ISO standards provide a structured framework for achieving these goals while fostering trust among stakeholders.

If you’re seeking ISO certification for paperboard manufacturing, reach out to us at [email protected] or call +91-8595603096 for expert assistance.

Applicable ISO Standards for Paperboard Manufacturing

Several ISO standards are directly or indirectly relevant to paperboard manufacturing. These standards address quality management, environmental impact, occupational safety, and more.

ISO 9001: Quality Management Systems (QMS)

ISO 9001 ensures that manufacturing processes consistently produce high-quality paperboard. This standard focuses on:

- Customer satisfaction

- Process efficiency

- Continuous improvement

ISO 14001: Environmental Management Systems (EMS)

Given the environmental impact of the paper industry, ISO 14001 helps manufacturers minimize waste, optimize resources, and comply with environmental regulations. Key aspects include:

- Sustainable resource management

- Pollution prevention

- Legal compliance

ISO 45001: Occupational Health and Safety Management Systems (OHSMS)

Ensuring worker safety is vital in a manufacturing setting. ISO 45001 helps paperboard companies reduce workplace risks, prevent accidents, and promote employee well-being.

ISO 50001: Energy Management Systems (EnMS)

With energy being a critical input in manufacturing, ISO 50001 aids in improving energy efficiency and reducing operational costs.

ISO 22000: Food Safety Management Systems (FSMS)

For manufacturers producing food-grade paperboard, ISO 22000 ensures the safety and quality of products intended for food contact applications.

ISO 9706: Permanence of Paper

This standard specifies requirements for the permanence and durability of paper and paperboard used for written, printed, and archival purposes.

ISO 186: Paper and Board - Sampling to Determine Average Quality

This standard outlines methods for sampling paperboard products to ensure consistent quality across batches.

Other Applicable Standards

- ISO 216: Specifications for paper sizes

- ISO 536: Determination of grammage (weight) of paperboard

- ISO 2470: Measurement of brightness in paperboard products

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in auditing and issuing ISO certifications tailored to your paperboard manufacturing processes. Our expertise ensures a seamless certification journey, helping your organization adhere to globally recognized standards. By choosing Pacific Certifications, you align your operations with the highest quality and safety benchmarks.

Looking to achieve ISO certification for your paperboard manufacturing business? Email us at [email protected] or give us a call at +91-8595603096.

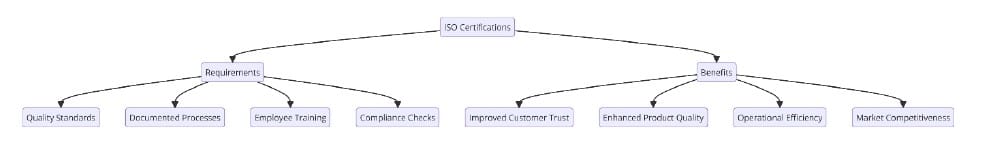

Requirements of ISO Certifications for Paperboard Manufacturing

To achieve ISO certification, paperboard manufacturers must fulfil specific criteria. While each standard has unique requirements, they all emphasize structured management systems, continuous improvement, and regulatory compliance.

ISO 9001: Quality Management Systems (QMS)

- Quality Objectives: Define measurable objectives aligned with the company’s strategic goals.

- Process Mapping: Identify and document all critical processes that influence quality.

- Customer Focus: Establish mechanisms for understanding and fulfilling customer requirements.

- Continuous Improvement: Implement processes for monitoring, analyzing, and improving performance.

- Internal Audits: Conduct regular audits to ensure compliance with the QMS.

- Documented Information: Maintain up-to-date records of procedures, processes, and results.

ISO 14001: Environmental Management Systems (EMS)

- Environmental Policy: Develop and maintain an environmental policy addressing key environmental impacts.

- Environmental Aspects and Impacts: Identify how manufacturing activities affect the environment, including resource usage, emissions, and waste.

- Legal Compliance: Ensure compliance with relevant environmental laws and regulations.

- Objectives and Targets: Set measurable environmental goals to improve performance.

- Operational Control: Implement controls to manage significant environmental impacts during production.

- Emergency Preparedness: Plan for potential environmental emergencies, such as spills or hazardous waste incidents.

- Monitoring and Measurement: Regularly track environmental performance and report progress.

ISO 45001: Occupational Health and Safety Management Systems (OHSMS)

- Health and Safety Policy: Establish a policy that promotes safe and healthy working conditions.

- Hazard Identification and Risk Assessment: Identify workplace hazards and assess risks to prevent accidents.

- Legal and Other Requirements: Stay compliant with local and international occupational health and safety regulations.

- Employee Participation: Involve workers in the development and implementation of health and safety measures.

- Training and Awareness: Educate employees on workplace hazards and safety protocols.

- Incident Investigation: Develop procedures for reporting, investigating, and addressing workplace incidents.

- Performance Monitoring: Continuously monitor and evaluate safety performance for improvements.

ISO 50001: Energy Management Systems (EnMS)

- Energy Policy: Establish an energy management policy that aligns with organizational goals.

- Energy Baseline: Analyze historical energy use to set a baseline for improvement.

- Energy Performance Indicators (EnPIs): Develop metrics to measure energy efficiency.

- Energy Objectives and Targets: Set achievable goals for energy performance improvements.

- Action Plans: Define specific projects or initiatives to enhance energy efficiency.

- Monitoring and Measurement: Track energy consumption, identify inefficiencies, and measure progress.

- Compliance: Meet applicable legal and regulatory requirements regarding energy usage.

ISO 22000: Food Safety Management Systems (FSMS)

- Food Safety Policy: Develop and communicate a food safety policy across the organization.

- Hazard Analysis and Critical Control Points (HACCP): Identify potential hazards and establish control measures to ensure safety.

- Prerequisite Programs (PRPs): Maintain hygiene, pest control, and sanitation measures.

- Traceability System: Implement a system to trace raw materials and finished products.

- Communication: Establish clear communication channels internally and with external stakeholders.

- Emergency Preparedness: Plan for food safety emergencies, such as contamination or recalls.

- Performance Evaluation: Conduct regular evaluations of food safety management effectiveness.

ISO 9706: Permanence of Paper

- Material Composition: Use raw materials that meet permanence criteria, including pH neutrality and reduced lignin content.

- Durability Testing: Verify that paperboard can withstand environmental factors like light and humidity.

- Documentation: Maintain records demonstrating compliance with permanence specifications.

ISO 186: Paper and Board - Sampling to Determine Average Quality

- Sampling Plan: Define methods for selecting representative samples.

- Testing Parameters: Determine properties such as thickness, grammage, and brightness.

- Statistical Analysis: Use statistical methods to evaluate quality consistency.

ISO 216: Specifications for Paper Sizes

- Size Compliance: Adhere to standardized dimensions (e.g., A4, A3) for specified paper grades.

- Measurement Accuracy: Verify precision during production to meet size tolerances.

ISO 536: Determination of Grammage of Paperboard

- Grammage Testing: Measure weight per square meter of paperboard.

- Calibration: Use calibrated equipment to ensure accuracy.

- Standard Conditions: Perform testing under controlled humidity and temperature.

Meeting these requirements demonstrates compliance with global standards, ensuring quality and sustainability in paperboard manufacturing. By aligning with these benchmarks, companies can build trust with customers, optimize operations, and contribute to a greener future.

For ISO certification tailored to paperboard manufacturing, connect with our team via [email protected] or call +91-8595603096.

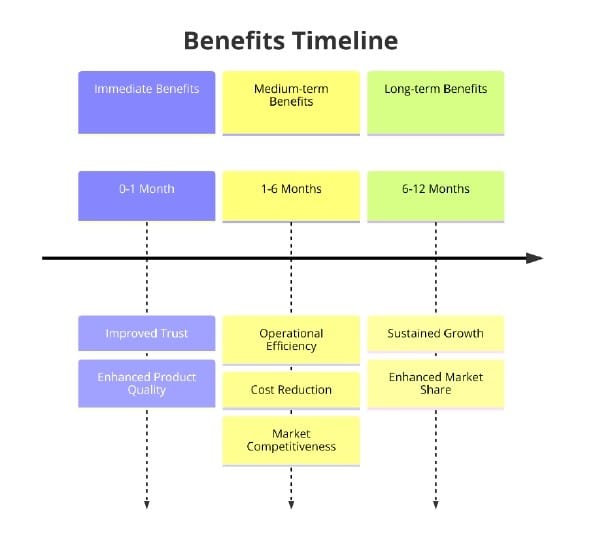

Benefits of ISO Certifications for Paperboard Manufacturing

Adopting ISO standards offers numerous advantages for paperboard manufacturers. From improved efficiency to market reputation, the benefits extend across various dimensions.

Product Quality: ISO 9001 ensures consistent product quality, which boosts customer satisfaction and reduces defects.

Sustainability: ISO 14001 supports eco-friendly manufacturing, helping companies reduce their carbon footprint and comply with environmental regulations.

Workplace Safety: ISO 45001 reduces workplace accidents and illnesses, fostering a safer working environment.

Cost Efficiency: ISO 50001 drives energy efficiency, lowering utility costs and improving profit margins.

Market Competitiveness: ISO-certified companies are perceived as reliable and trustworthy, giving them a competitive edge in global markets.

Compliance: Adhering to ISO standards ensures compliance with local and international regulations, avoiding legal complications.

In this year, sustainability and digital innovation dominate the paperboard manufacturing landscape. Market research indicates a growing demand for recyclable and biodegradable paperboard products. Additionally, advancements in digital printing technologies have opened new avenues for customization and design.

Adopting ISO certifications is becoming a strategic imperative, with businesses leveraging these certifications to showcase their commitment to sustainability and quality. Regulatory bodies are also tightening standards, making ISO compliance a necessity for market participation.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Paperboard Manufacturing business, please contact us at [email protected] or +91-8595603096.

FAQs: ISO Certifications for Paperboard Manufacturing

What is the importance of ISO certifications for paperboard manufacturing?

ISO certifications ensure compliance with quality, environmental, and safety standards, improving product reliability and market trust.

How can Pacific Certifications assist in obtaining ISO certifications?

Pacific Certifications conducts audits and issues ISO certifications to paperboard manufacturers, ensuring seamless compliance with required standards.

Which ISO standards are most relevant to the paperboard industry?

Key standards include ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ISO 45001 (Occupational Health and Safety), and ISO 50001 (Energy Management).

How long does the ISO certification process take for paperboard manufacturers?

The duration depends on the complexity of your operations and the specific standard pursued. Typically, the process takes a few weeks to a few months.

Are ISO certifications mandatory for paperboard manufacturers?

While not mandatory, ISO certifications are highly beneficial for meeting regulatory requirements and enhancing market competitiveness.

What are the costs associated with ISO certification?

Costs vary based on the size of the organization, the scope of the certification, and the standard pursued. Contact Pacific Certifications for a customized quote.

Read More at: Blogs by Pacific Certifications