ISO Certifications for Machine Tool Manufacturing Businesses, Requirements and Benefits

Introduction to ISO Standards for Machine Tool Manufacturing

In the dynamic world of machine tool manufacturing, quality and precision are paramount. To meet global demands and ensure compliance with international standards, ISO certifications for machine tool manufacturing play a vital role. These certifications not only help companies streamline operations but also strengthen customer trust and market reputation.

ISO standards serve as a global benchmark for quality and efficiency across industries. In the machine tool manufacturing sector, they provide a framework for achieving excellence through consistent processes and adherence to safety protocols.

The machine tool industry has undergone significant advancements, requiring manufacturers to adopt innovative practices while ensuring product reliability. ISO standards provide a structured approach to meeting these challenges. By achieving certification, businesses demonstrate their commitment to quality and environmental responsibility.

Ready to elevate your machine tool manufacturing standards? Contact us at [email protected] or call +91-8595603096 to start your ISO certification journey.

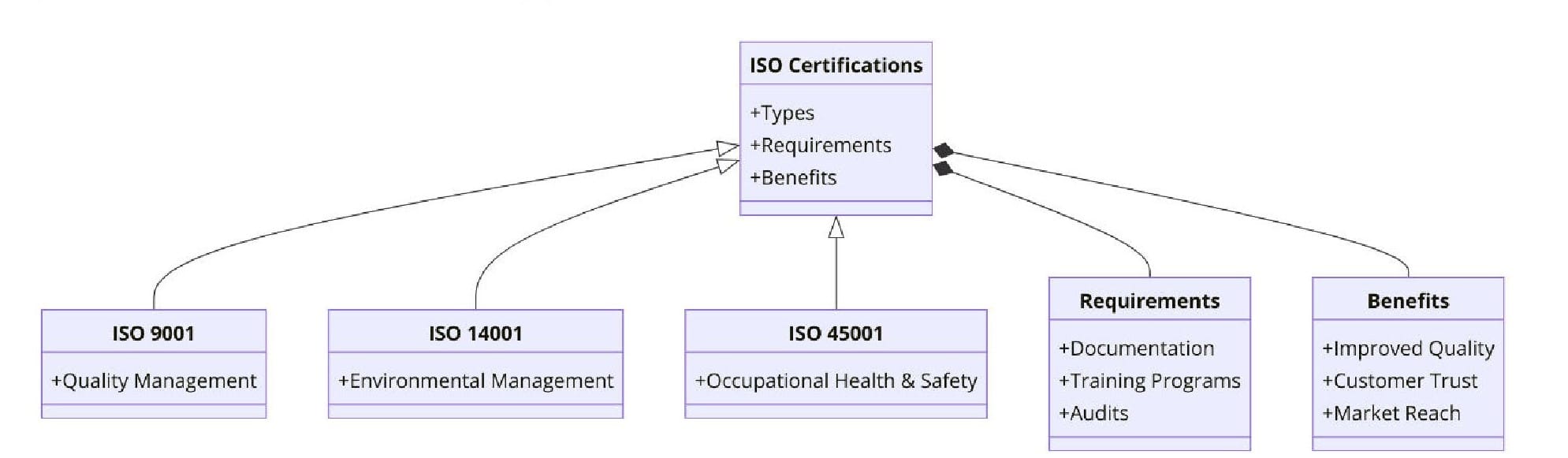

Applicable ISO Standards for Machine Tool Manufacturing

Several ISO standards apply directly to machine tool manufacturing, addressing various aspects of production, quality management, and environmental sustainability:

ISO 9001: Quality Management Systems (QMS)

This widely recognized standard focuses on delivering consistent quality by emphasizing customer satisfaction, process efficiency, and continual improvement. Machine tool manufacturers certified to ISO 9001 ensure robust quality controls at every production stage.

ISO 14001: Environmental Management Systems (EMS)

Machine tool manufacturing often involves processes with environmental implications. ISO 14001 helps businesses manage their environmental impact, reduce waste, and achieve sustainability goals.

ISO 45001: Occupational Health and Safety Management Systems

Worker safety is a priority in manufacturing environments. ISO 45001 provides guidelines for identifying workplace hazards, reducing risks, and fostering a safe and healthy workspace.

ISO 14955: Eco-design for Machine Tools

This standard promotes energy-efficient designs in machine tools, helping manufacturers produce machines with reduced environmental impact.

ISO 23125: Safety of Machine Tools

Specific to turning machines, this standard outlines safety requirements to ensure operators' protection and prevent accidents during operation.

ISO 50001: Energy Management Systems

Efficient energy use is critical in modern manufacturing. ISO 50001 helps organizations improve energy performance, reduce energy costs, and enhance sustainability efforts.

ISO/TS 19807: Additive Manufacturing Processes

For manufacturers involved in advanced additive manufacturing, this standard provides technical specifications to ensure process consistency and product quality.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we understand the complexities of achieving and maintaining ISO certifications in the competitive world of machine tool manufacturing. As a trusted certification body, we specialize in conducting audits and issuing ISO certificates that validate your organization’s adherence to international standards.

Our seamless certification process ensures businesses meet industry benchmarks without unnecessary delays. Whether you are pursuing your first certification or need re-certification, our experienced auditors guide you every step of the way.

Need ISO certification for your machine tool manufacturing business? Email [email protected] or call +91-8595603096 today to ensure compliance and quality excellence.

Requirements of ISO Certifications for Machine Tool Manufacturing

To achieve ISO certification, organizations must meet specific requirements unique to each standard. Below is a detailed breakdown of the requirements for each applicable ISO standard in machine tool manufacturing.

ISO 9001: Quality Management Systems (QMS) Requirements

ISO 9001 emphasizes consistency, quality, and customer satisfaction. Key requirements include:

- Establishing a Quality Management System (QMS): Organizations must define, document, and implement processes to ensure quality at every stage of production.

- Leadership Commitment: Top management must demonstrate leadership by establishing quality objectives, allocating resources, and maintaining clear communication.

- Customer Focus: Identify customer requirements and ensure consistent delivery of products that meet or exceed their expectations.

- Process Approach: Define processes, interactions, and performance metrics, ensuring efficiency and effectiveness.

- Continuous Improvement: Monitor and measure performance to identify opportunities for improvement using methods like PDCA (Plan-Do-Check-Act).

- Risk-Based Thinking: Assess risks and opportunities to minimize uncertainties in the manufacturing process.

ISO 14001: Environmental Management Systems (EMS) Requirements

ISO 14001 focuses on minimizing environmental impact. Key requirements include:

- Environmental Policy: Develop a clear environmental policy outlining the organization’s commitment to sustainable practices.

- Environmental Aspects and Impacts: Identify environmental aspects (e.g., emissions, waste, resource consumption) and evaluate their impacts.

- Legal Compliance: Adhere to relevant environmental laws, regulations, and standards.

- Objectives and Targets: Set measurable environmental goals, such as reducing waste or energy consumption.

- Monitoring and Measurement: Establish methods to track environmental performance and regularly review improvements.

- Emergency Preparedness: Develop plans to address potential environmental emergencies, such as spills or emissions.

ISO 45001: Occupational Health and Safety Management Systems Requirements

ISO 45001 ensures workplace safety and promotes employee well-being. Key requirements include:

- Hazard Identification: Identify potential health and safety hazards in the workplace, including ergonomic, physical, and chemical risks.

- Risk Assessment and Control: Evaluate identified hazards and implement effective controls to mitigate risks.

- Worker Participation: Involve employees in safety initiatives, including reporting hazards and contributing to risk assessments.

- Compliance Obligations: Meet national and international occupational health and safety regulations.

- Emergency Preparedness: Establish protocols for managing workplace emergencies, ensuring safety and rapid response.

- Continual Improvement: Regularly review and improve safety management systems to adapt to changing conditions.

ISO 50001: Energy Management Systems (EnMS) Requirements

ISO 50001 helps organizations optimize energy use and enhance energy efficiency. Key requirements include:

- Energy Policy: Define an energy policy that commits to efficient energy use and aligns with organizational goals.

- Energy Baseline and Planning: Establish an energy baseline by analyzing historical energy usage data and identifying key areas for improvement.

- Energy Performance Indicators (EnPIs): Define measurable indicators to track energy performance.

- Energy Objectives and Targets: Set specific, measurable, and achievable energy-saving targets.

- Operational Control: Identify significant energy uses and implement operational controls to improve efficiency.

- Employee Awareness: Train employees to adopt energy-efficient practices within their roles.

ISO 14955: Eco-Design for Machine Tools Requirements

ISO 14955 focuses on reducing environmental impacts through machine tool design. Key requirements include:

- Energy Efficiency: Design machine tools with features that minimize energy consumption during operation and standby.

- Life Cycle Assessment: Evaluate the environmental impact of a machine tool from raw material extraction to end-of-life disposal.

- Component Selection: Use materials and components that enhance sustainability, such as recyclable or energy-efficient options.

- Performance Measurement: Implement tools to measure and improve the eco-efficiency of machine tools.

ISO 23125: Safety of Machine Tools Requirements

ISO 23125 is specific to safety in turning machines. Key requirements include:

- Risk Assessment: Identify potential safety hazards during machine operation, such as entanglement, tool ejection, or pinch points.

- Protective Measures: Implement guards, safety barriers, and interlocking systems to prevent accidents.

- Emergency Stop Functions: Equip machines with reliable emergency stop mechanisms to halt operations in hazardous situations.

- Ergonomics: Ensure machine tools are designed for operator comfort and ease of use, reducing the likelihood of errors.

- Documentation: Provide clear instructions and maintenance manuals for safe operation and servicing of machines.

ISO/TS 19807: Additive Manufacturing Processes Requirements

ISO/TS 19807 applies to manufacturers leveraging additive manufacturing (AM) technologies. Key requirements include:

- Material Specifications: Use approved materials compatible with the specific AM process and intended application.

- Process Consistency: Establish and maintain stable process parameters to ensure consistent product quality.

- Testing and Validation: Conduct tests to verify that AM-produced parts meet mechanical, dimensional, and performance criteria.

- Documentation and Traceability: Maintain detailed records of AM processes, materials, and quality checks.

By meeting these requirements, machine tool manufacturers not only achieve compliance but also position themselves as leaders in quality, sustainability, and safety. For expert certification services, contact [email protected].

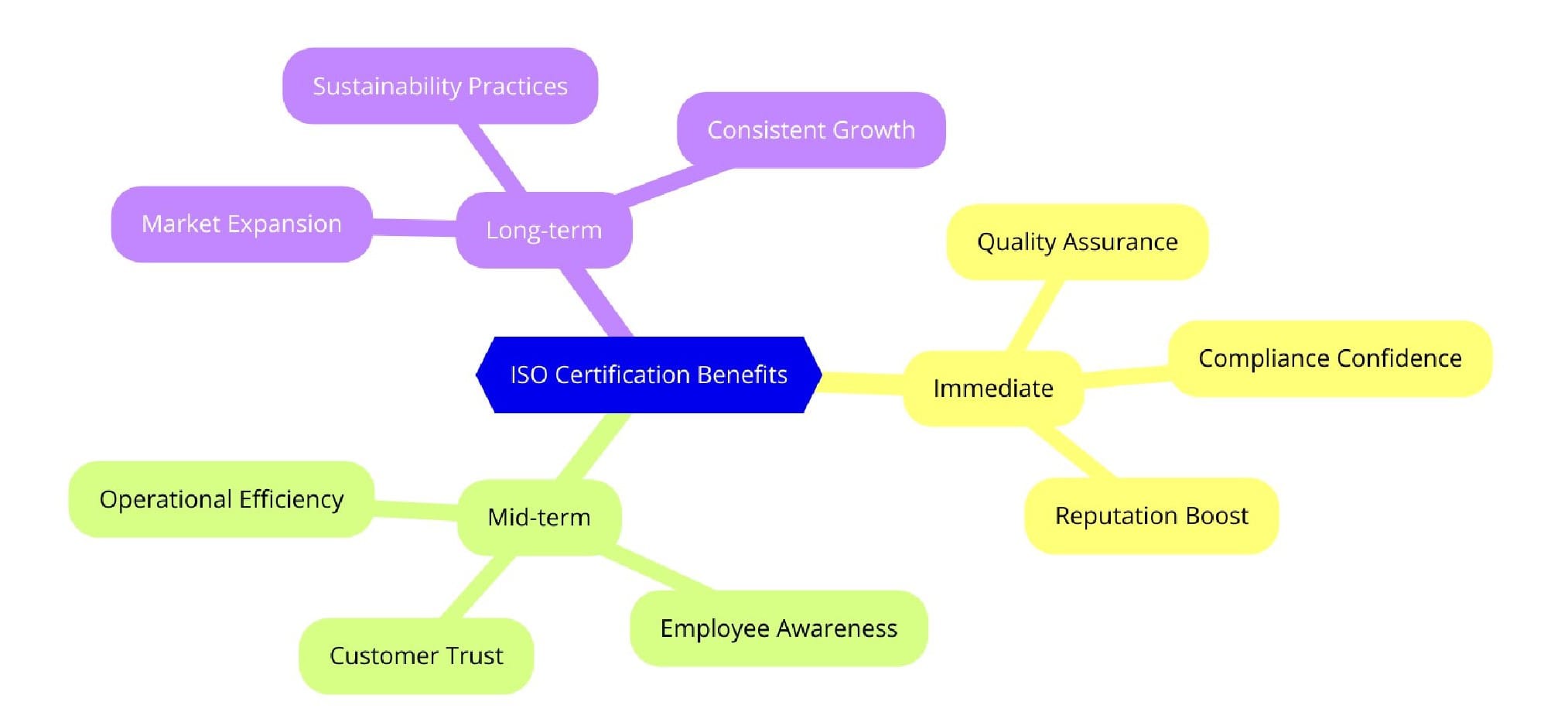

Benefits of ISO Certifications for Machine Tool Manufacturing

Adopting ISO certifications offers a myriad of advantages for machine tool manufacturers. These benefits extend beyond compliance, positively impacting operational efficiency, market positioning, and customer satisfaction.

Product Quality: ISO standards ensure strict quality control measures, leading to reliable and high-performing machine tools that meet or exceed customer expectations.

Global Market Access: ISO-certified manufacturers gain a competitive edge by meeting international quality and safety requirements, facilitating entry into global markets.

Operational Efficiency: Streamlined processes and systematic audits foster operational efficiency, reducing production costs and minimizing wastage.

Environmental Sustainability: By aligning with standards like ISO 14001 and ISO 50001, manufacturers reduce their environmental footprint, which resonates with environmentally conscious consumers.

Worker Safety: Implementing ISO 45001 enhances workplace safety, reducing accidents and boosting employee morale and productivity.

Risk Mitigation: Compliance with ISO standards minimizes operational risks, enhances crisis preparedness, and ensures regulatory compliance.

ISO certification made simple for machine tool manufacturers! Reach out to us via email at [email protected] or call +91-8595603096 for assistance.

In this year, the machine tool industry is witnessing transformative trends driven by digitalization and sustainability. Manufacturers are increasingly integrating IoT (Internet of Things) and AI-driven solutions into production processes. Meanwhile, ISO standards are evolving to address these technological advancements, ensuring safety and efficiency in modern manufacturing practices.

Research indicates a growing preference for energy-efficient and eco-friendly machine tools, aligning with the objectives of standards like ISO 14001 and ISO 50001. This shift not only reduces environmental impact but also appeals to environmentally conscious buyers.

Achieving ISO certification is more than a compliance measure; it’s a strategic step towards growth and excellence in machine tool manufacturing. With Pacific Certifications, your journey toward certification is seamless, efficient, and rewarding.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Machine Tool manufacturing business, please contact us at [email protected] or +91-8595603096.

FAQs: ISO Certifications for Machine Tool Manufacturing

What is the significance of ISO certifications in machine tool manufacturing?

ISO certifications ensure that machine tool manufacturers adhere to global quality, safety, and environmental standards, enhancing product reliability and customer trust.

Which ISO standards are most relevant for machine tool manufacturing?

Key standards include ISO 9001, ISO 14001, ISO 45001, ISO 50001, and ISO 23125, among others. Each focuses on specific aspects like quality, safety, or sustainability.

How does ISO 50001 benefit machine tool manufacturers?

ISO 50001 helps manufacturers optimize energy use, reduce energy costs, and achieve sustainability goals, aligning with modern energy efficiency trends.

Why should I choose Pacific Certifications for ISO certification?

Pacific Certifications offers expert auditing and certification services, ensuring your compliance with ISO standards through a seamless and efficient process.

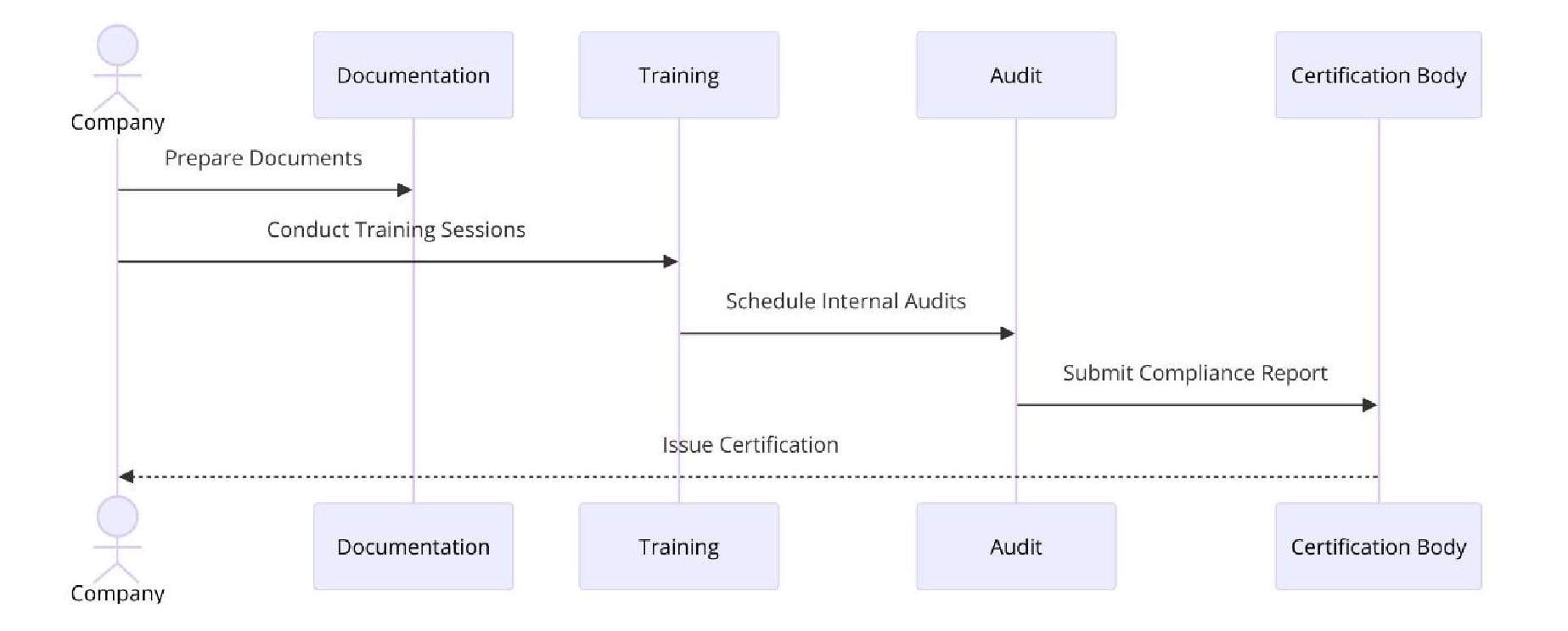

What is the process for obtaining ISO certification?

The process includes gap analysis, internal audits, implementing required changes, and final certification audits conducted by an accredited body like Pacific Certifications.

How do ISO standards promote environmental sustainability in manufacturing?

ISO standards like ISO 14001 and ISO 50001 encourage the adoption of eco-friendly practices, reducing waste, energy consumption, and the overall environmental footprint.

Read More at: Blogs by Pacific Certifications