ISO Certifications for Automotive Industry Requirements and Benefits

Introduction

The automotive industry is one of the largest and most complex sectors in the world, driving global trade, employment, and innovation. With the rise of electric vehicles (EVs), autonomous driving technologies, and stricter environmental regulations, manufacturers and suppliers face increasing pressure to deliver safe and sustainable products.

According to research, the global automotive market is projected to exceed USD 6.5trillion by 2030, with EVs expected to represent nearly 40% of total vehicle sales. This growth brings opportunities but also challenges, including regulatory compliance and sustainability demands. ISO certifications give automotive companies structured frameworks to meet these expectations and to build trust with regulators and consumers.

In the automotive sector, ISO certifications provide assurance of quality, safety, and compliance across design, manufacturing, and supply chains

For ISO certification support, contact [email protected].

Quick summary

ISO certifications help automotive companies ensure safety, quality, and sustainability. Key standards include IATF 16949 (automotive quality), ISO 26262 (functional safety), ISO 14001 (environment), and ISO/SAE 21434 (cybersecurity). Certification improves reliability, regulatory compliance, and trust in one of the world’s most advanced industries.

Applicable ISO standards for Automotive Industry

Below are some of the key ISO standards applicable to the automotive industry:

ISO 9001:2015 - Quality Management Systems (QMS)

This standard provides a framework for quality management. Many automotive companies, both manufacturers and suppliers, seek ISO 9001 certification to demonstrate their commitment to quality.

IATF 16949:2016 - Quality Management System for Automotive Suppliers

IATF 16949 is a globally recognized standard developed by the International Automotive Task Force (IATF) in collaboration with ISO. It outlines specific quality management system requirements for automotive suppliers and is often required by major automakers as a prerequisite for doing business with them.

ISO 14001:2015 - Environmental Management Systems (EMS)

ISO 14001 sets the standard for environmental management systems. Automotive companies use this standard to demonstrate their commitment to environmental sustainability and compliance with environmental regulations.

ISO 45001:2018 - Occupational Health and Safety Management Systems (OHSMS)

ISO 45001 provides a framework for occupational health and safety management systems. It helps automotive companies establish systems and processes to protect the health and safety of employees and other stakeholders.

ISO 26262 - Road Vehicles - Functional Safety

ISO 26262 is critical for the automotive industry as it deals with the functional safety of electrical and electronic systems in road vehicles. It outlines guidelines and requirements for the development of safety-critical automotive systems to minimize the risk of failures leading to accidents.

ISO 50001:2018 - Energy Management Systems (EnMS)

ISO 50001 provides a framework for energy management systems, which is relevant for automotive companies looking to optimize energy efficiency in their operations and reduce energy costs.

ISO 10002:2018 - Customer Satisfaction - Guidelines for Complaints Handling in Organizations

Ensuring customer satisfaction is crucial in the automotive industry. ISO 10002 provides guidelines for handling customer complaints effectively, helping companies address customer concerns and improve their products and services.

ISO 12100:2010 - Safety of Machinery - General Principles for Design - Risk Assessment and Risk Reduction

ISO 12100 is often applied to assess and mitigate risks associated with machinery used in automotive manufacturing processes.

ISO 13485:2016 - Medical devices - Quality Management Systems - Requirements for Regulatory Purposes

This standard is relevant for automotive companies that produce medical devices or components for the healthcare industry, which is sometimes a part of the automotive supply chain.

ISO 15408 - Common Criteria for Information Technology Security Evaluation:

While not exclusive to the automotive industry, ISO 15408 can be relevant for assessing and ensuring the cybersecurity of automotive systems, especially as vehicles become increasingly connected and reliant on electronic systems.

These ISO standards play important role in helping automotive companies ensure the quality & safety of their products and services, maintain compliance with industry regulations, and improve overall business processes.

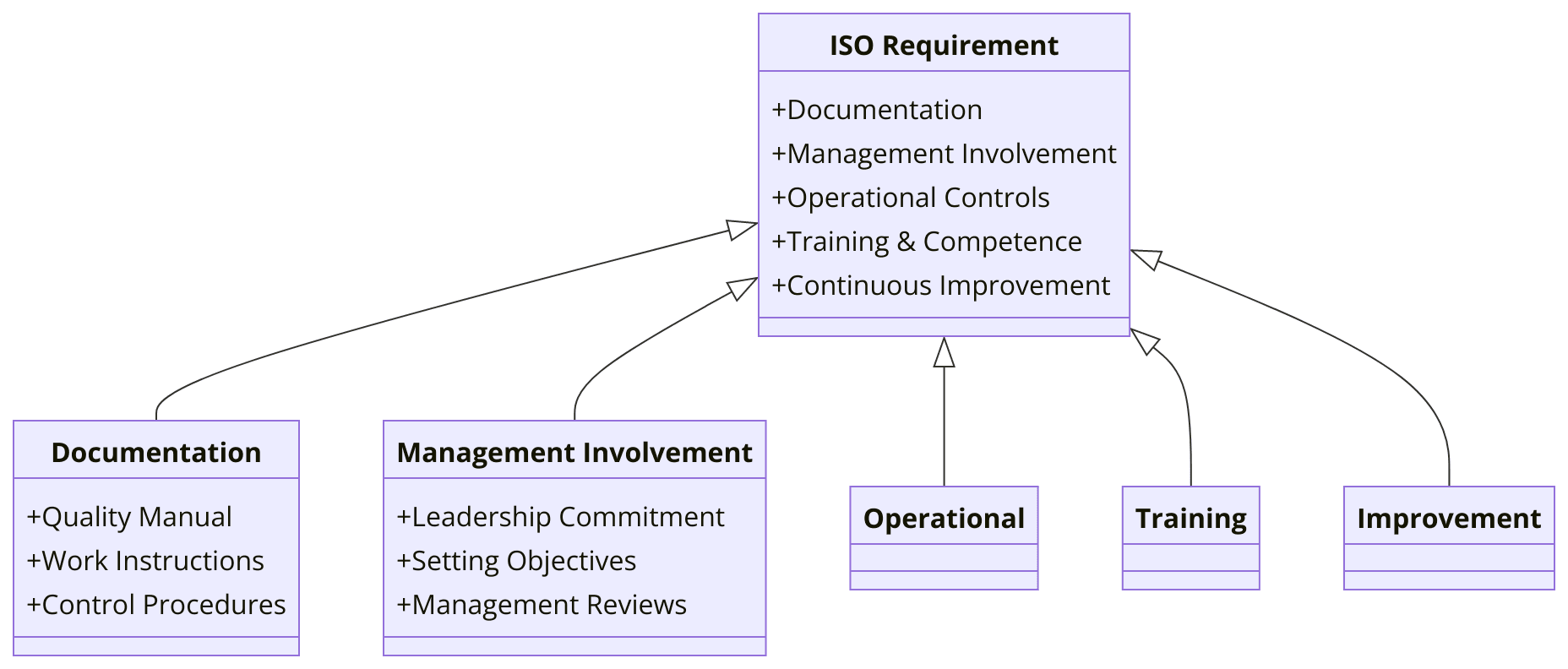

What are the requirements of ISO Certifications for Automotive Industry?

ISO certifications in the automotive industry have specific requirements that organizations must meet to achieve and maintain certification. Here are some key requirements for commonly used ISO certifications in the automotive industry:

ISO 9001:2015 - Quality Management System (QMS) requirements:

Establish a quality policy and quality objectives.

Document the organization's processes and procedures.

Implement a system for document control and record keeping.

Monitor customer satisfaction and manage customer feedback.

Conduct internal audits and management reviews.

Continually improve the QMS and processes.

IATF 16949:2016 - Quality Management System for Automotive Suppliers requirements:

Comply with the specific requirements outlined in IATF 16949, which are tailored to the automotive industry.

Implement a robust process for product quality and safety.

Address risk management and contingency planning.

Ensure traceability of products and parts throughout the supply chain.

Demonstrate compliance with applicable legal and regulatory requirements.

Conduct regular internal audits and participate in external audits by certification bodies.

ISO 14001:2015 - Environmental Management System (EMS) requirements

Develop an environmental policy and set environmental objectives.

Identify environmental aspects and assess their impacts.

Establish an environmental management program.

Monitor and measure environmental performance.

Ensure compliance with environmental legal and regulatory requirements.

Continually improve the EMS and environmental performance.

ISO 45001:2018 - Occupational Health and Safety Management System (OHSMS) requirements:

Develop an OH&S policy and OH&S objectives.

Identify workplace hazards and assess risks.

Implement controls to mitigate OH&S risks.

Establish emergency response plans and procedures.

Ensure compliance with OH&S legal and regulatory requirements.

Continually improve the OHSMS and OH&S performance.

ISO 26262 - Road Vehicles - Functional Safety requirements:

Develop a functional safety management system.

Identify safety goals and define the necessary safety integrity levels (SIL).

Conduct hazard analysis and risk assessments.

Implement safety measures and safety mechanisms.

Verify and validate the functional safety of electronic systems in vehicles.

Maintain comprehensive documentation of safety-related activities.

ISO 50001:2018 - Energy Management System (EnMS) requirements:

Establish an energy policy and set energy performance objectives.

Identify significant energy uses and assess energy consumption.

Develop an energy management program to improve energy efficiency.

Monitor, measure, and analyze energy performance.

Comply with energy-related legal and regulatory requirements.

Continually improve energy performance and reduce energy consumption.

ISO 10002:2018 - Customer Satisfaction - Guidelines for Complaints Handling in Organizations requirements:

Develop a customer complaints handling process.

Ensure effective resolution of customer complaints.

Monitor and measure customer satisfaction and feedback.

Continually improve the complaints handling process.

General requirements:

Define the scope of certification (design, manufacturing, supply chain, or aftersales).

Establish policies for quality, safety, environmental care, and data security.

Conduct risk assessments for product defects, workplace safety, and supply chain interruptions.

Document processes for design validation, production, testing, and distribution.

Train staff in quality control, safety protocols, and compliance with automotive standards.

Maintain records of inspections, testing results, audits, and corrective actions.

Track KPIs such as defect rates, warranty claims, accident records, and energy use.

Perform regular audits and management reviews to ensure system effectiveness.

Tip: Start with ISO 9001 if you are an automotive manufacturer or supplier. Supporting standards like ISO 14001 and ISO 26262 can then be added for environment and safety compliance.

Meeting these requirements involves implementing and maintaining documentations & processes within the organization. It also involves regular internal audits and external assessments by certification bodies to ensure ongoing compliance with the standards.

Contact us today to start your certification journey!

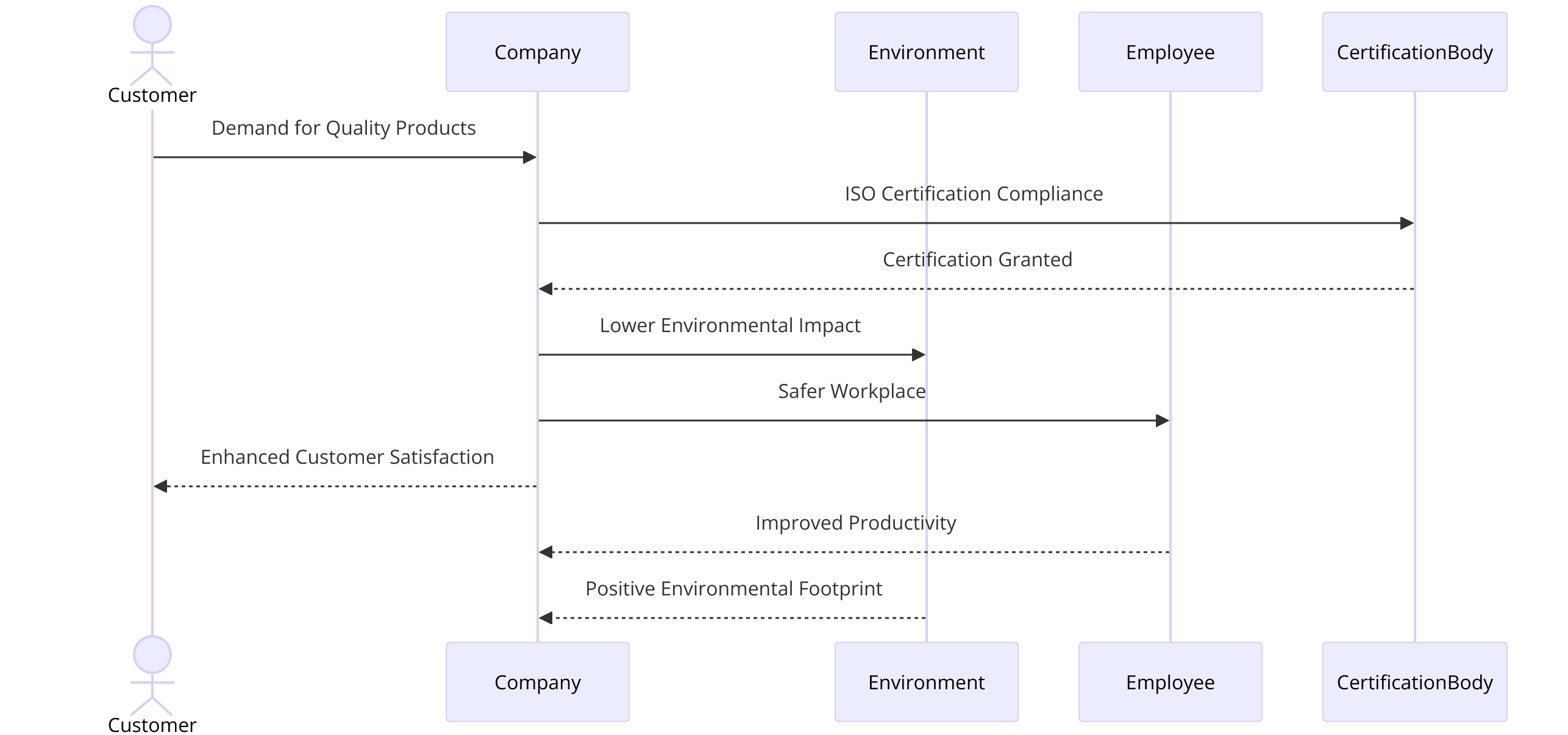

What are the benefits of ISO Certifications for Automotive Industry?

ISO certifications offer various benefits to organizations in the automotive industry. These certifications provide a framework from quality, safety to other essential aspects of automotive manufacturing and service. Here are some key benefits:

ISO 9001 and IATF 16949 certifications help organizations establish and maintain quality management systems, leading to improved product and service quality.

Enhanced quality often results in higher customer satisfaction.

ISO certifications help automotive companies to enter global markets and compete on a global scale.

ISO standards are often prerequisites for doing business with major automakers.

ISO 14001 certification demonstrates an organization's commitment to environmental sustainability.

Compliance with environmental regulations can lead to cost savings and a reduced environmental footprint.

ISO 45001 certification helps organizations protect the health and safety of their employees and stakeholders.

ISO 26262 certification ensures that safety-critical electronic systems in vehicles are developed with a focus on risk mitigation.

ISO 50001 certification promotes energy management and efficiency.

Reducing energy consumption not only lowers operational costs but also demonstrates commitment to sustainability.

Implementing ISO standards often involves documenting processes, which leads to greater transparency and consistency.

Well-defined processes reduce errors, waste, and operational inefficiencies.

ISO certifications help organizations stay up-to-date with evolving industry regulations and standards.

ISO standards require organizations to continually monitor and improve their systems and processes.

ISO certifications encourage organizations to identify and assess risks.

ISO-certified organizations can use their certifications as a competitive differentiator.

The automotive industry is being reshaped by electrification and digitalization. Electric vehicles are rapidly increasing their share of the market, creating demand for ISO 26262 and ISO/SAE 21434 to manage safety and cybersecurity in advanced systems.

Sustainability remains central, with automakers investing heavily in low-emission manufacturing and recycling initiatives. Standards such as ISO 14001 and ISO 50001 are being adopted to reduce environmental impact and energy consumption.

At the same time, supply chain resilience is now a key priority after disruptions from global events. Companies are turning to ISO 22301 for continuity planning. With consumer expectations for safety, data security, and reliability at an all-time high, ISO certifications are increasingly part of mandatory requirements in contracts with major OEMs.

How Pacific Certifications can help?

Pacific Certifications, accredited by ABIS, provides certification and auditing services across the automotive industry. From OEMs to Tier-1 and Tier-2 suppliers, we support businesses in aligning with international standards and contractual requirements.

With Pacific Certifications, you can:

Achieve certification for IATF 16949, ISO 9001, ISO 26262, ISO 14001, ISO 45001, ISO/SAE 21434, and more.

Strengthen compliance with regulatory and safety requirements.

Build confidence with OEMs, suppliers, and customers through accredited certification.

Adopt structured systems that support long-term performance.

If you need more support with ISO certification for your business in Automotive Industry, please contact us at +91-8595603096 or [email protected].

Written by: Sony

Read more: ISO Certifications for Aerospace industry Requirements and Benefits