ISO 9001 Processes, Procedures, Work Instructions and Certification & Audit Services

Introduction

In an increasingly competitive marketplace, quality is not only a differentiator, it is a necessity. If you are an organization that is seeking consistency, customer satisfaction and continual improvement, ISO 9001 is the world’s most trusted standard for Quality Management Systems (QMS) that organizations can implement. However, if your organization sees obtaining ISO 9001 certification as very simply writing a quality policy statement and moving on to other matters you are going to miss the main ingredient, quality assurance. Obtaining ISO 9001 certification requires an organized approach that includes written processes, procedures and work instructions, and many organizations are more confused on what those mean and the value.

The foundation of a well-functioning QMS is the simple act of moving an organization from quality control in a reactive state, to quality assurance in a proactive state. A well-developed QMS will not serve as a reporting tool, but will also turn daily operations into measurable, repeatable and continually improving processes that meet both the customer and regulatory expectations. Whether you’re leading a manufacturing plant, service company, or public institution, obtaining ISO 9001 certification supports your organization in creating a foundation of accountability and performance.

Discuss your certification plan with an auditor at Pacific Certifications and identify how ISO 9001 can help your organization standardize, improve and sustain quality performance.

Quick summary

ISO 9001:2015 establishes the framework for building a Quality Management System based on the Plan-Do-Check-Act (PDCA) model. It defines the need for documented processes, clear procedures and operational work instructions to achieve quality consistency and continual improvement. The standard applies to organizations of all sizes and industries, focusing on process-based management rather than departmental silos.

Why ISO 9001 matters for organizations?

ISO 9001 certification remains one of the most recognized management standards globally, with over a million organizations certified. It provides assurance that a company can consistently deliver products and services meeting customer and legal requirements.

Implementing ISO 9001 builds credibility, strengthens customer trust and supports operational resilience. It allows organizations to identify inefficiencies, reduce defects and establish measurable KPIs that drive consistent quality outcomes.

“A strong Quality Management System is not about paperwork, it’s about creating clarity, accountability and reliability across every process that impacts the customer.”

Understanding processes, procedures and work instructions under ISO 9001

Before implementation, it is important to distinguish how these three components work together within a Quality Management System:

Processes: High-level activities that convert inputs into outputs to achieve organizational objectives (e.g., production, procurement, sales).

Procedures: Documented methods describing how specific processes are carried out (e.g., supplier evaluation, corrective action handling).

Work instructions: Step-by-step operational guidelines explaining how to perform specific tasks (e.g., machine setup, inspection steps).

Together, these ensure standardization, reduce variation and support continuous improvement across all operational levels.

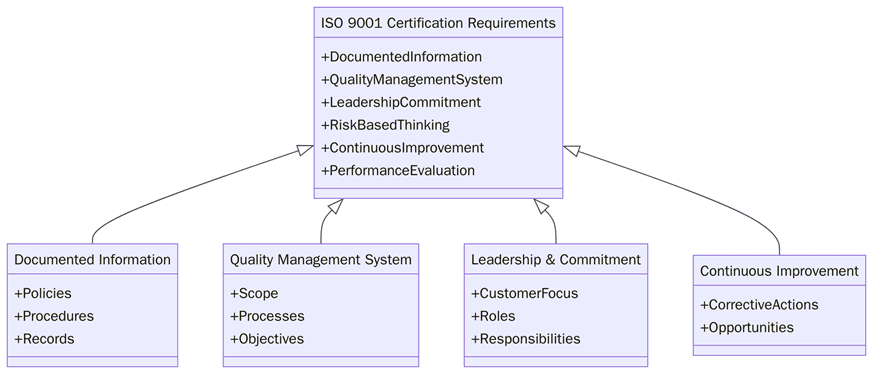

What are the requirements for ISO 9001 certification?

To achieve ISO 9001 certification, organizations must establish a structured Quality Management System with defined processes and supporting documentation. Below are the key requirements:

Define the scope of the QMS, identifying products, services and locations covered.

Develop a quality policy and measurable quality objectives.

Map processes and determine their inputs, outputs and interrelations.

Document procedures for control of nonconforming products, internal audits and management reviews.

Create work instructions where task-level consistency is critical.

Implement documented information control systems for version and approval management.

Establish risk-based thinking to identify potential failures and corrective actions.

Conduct performance monitoring and data-driven analysis.

Engage leadership to review the QMS regularly for adequacy and improvement.

Maintain evidence of continual improvement across all areas.

Tip:Start by aligning your existing procedures with ISO 9001 clauses to identify documentation gaps before developing new work instructions.

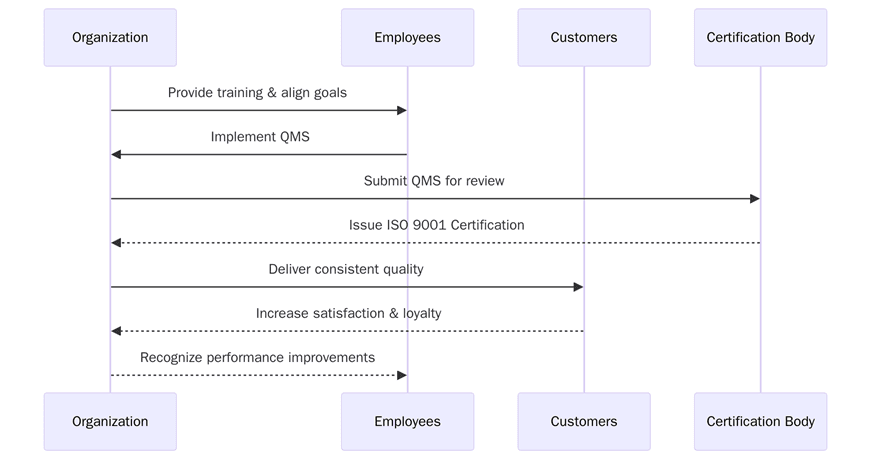

How to prepare for ISO 9001 certification?

Preparing for ISO 9001 requires planning, communication and commitment across the organization.

Conduct a gap analysis to evaluate current systems against ISO 9001 requirements.

Train management and teams on quality objectives and roles.

Document core processes and establish measurable performance indicators.

Implement control mechanisms for documents, products and nonconformities.

Perform internal audits to assess compliance and identify improvement areas.

Conduct a management review to confirm readiness for external certification.

Certification audit

Stage 1 audit: Evaluates the organization’s documented processes, quality policy and objectives.

Stage 2 audit: Verifies implementation, employee awareness and performance evidence across departments.

Nonconformities: Identified issues must be corrected and verified with documented evidence.

Management review: Confirms leadership commitment to quality performance and continual improvement.

Final certification: Granted upon successful audit completion.

Surveillance audits: Conducted annually to monitor ongoing compliance.

Recertification audits: Performed every three years to maintain certification validity.

What are the benefits of ISO 9001 certification?

Implementing ISO 9001 offers measurable advantages across quality, efficiency and credibility. Below are the key benefits:

Increased customer satisfaction through consistent product and service quality.

Streamlined workflows with clear documentation and accountability.

Reduced operational errors and rework costs.

Improved employee engagement through structured roles and training.

Stronger supplier relationships and evaluation systems.

Data-driven decision-making through continual performance analysis.

Better market access and competitiveness in global tenders.

Integration opportunities with ISO 14001 and ISO 45001.

Enhanced reputation through third-party certification and audit validation.

KPI improvements such as defect rate reduction, on-time delivery and customer complaint decrease.

Recent Trends

In recent years, organizations are integrating ISO 9001 with digital quality systems and AI-based analytics to improve data accuracy and real-time monitoring. Paperless audits, remote QMS platforms and automated corrective action tracking have made certification more efficient. Companies are also linking ISO 9001 metrics to ESG and sustainability reporting frameworks, emphasizing quality as part of responsible governance.

By 2030, ISO 9001 is expected to evolve with stronger focus on digital traceability, cyber-physical systems and AI-supported quality assurance. Organizations that align early with these advancements will reduce quality-related losses by up to 40% and increase audit transparency through data-driven QMS dashboards. Certification will continue to serve as a recognized trust mark in both traditional and digital supply chains.

Training and courses

Pacific Certifications provides accredited training programs for ISO 9001, designed for professionals aiming to build and maintain a high-performing Quality Management System:

Lead Auditor Training: For professionals auditing ISO 9001 systems, covering audit principles, performance evaluation and nonconformity assessment techniques.

Lead Implementer Training: For managers and quality officers responsible for developing and improving internal quality processes, focusing on documentation, risk-based thinking and process control.

To schedule training or ISO 9001 awareness sessions, contact [email protected].

How Pacific Certifications can help?

Pacific Certifications provides ISO 9001 certification and audit services to organizations across industries. Our accredited audits evaluate process effectiveness, documentation quality and compliance with ISO 9001:2015 requirements.

We issue ISO 9001 certificates of conformity following impartial audits that verify process control, performance evaluation and continual improvement practices. As an accredited certification body, Pacific Certifications focuses solely on audit and certification, not consultancy - ensuring credibility and transparency in every assessment.

Contact Us

To request your ISO 9001 audit plan and Stage-1/Stage-2 timeline, contact us at [email protected] or visit www.pacificcert.com.

Read more: Pacific Blogs