Designing for Circularity: ISO 59000 Series & EPR Laws

As sustainability increases in focus globally, it is bringing the circular economy model which both reduces waste and utilizes resources smoothly to the forefront. Central to this movement is the need for businesses to change how products are designed, updated, supplied and how business models interact with these products to keep resources in circulation as long as possible. Furthermore, ISO 59000 series and Extended Producer Responsibility (EPR) laws provide governing practices and guidelines for organizations to achieve circularity and required both for compliance to existing regulations in business for compliance with regulations, which considers sustainable development in its broadest context.

This blog will look at how the ISO 59000 series, ISO 59004 and ISO 59010, in particular can assist businesses to practice the principles of circular economy and also how using ISO 14025, ISO 20887 and ultimately even EPR compliance help to support good product stewardship and the circular economy as a whole.

For assistance, contact us at [email protected].

Introduction

The circular economy aims to reduce waste, lengthen the life of products, and reclaim valuable materials. Adopting the circular economy means businesses must rethink product design, production processes, and disposal methods to better close the loop on all resource use. Standards such as the ISO 59000 series and EPR laws are able to facilitate the transition to a circular economy by laying the foundation for sustainable product design, waste prevention and better environmental impact management.

The ISO 59000 series, which comprises ISO 59004 and ISO 59010, offer businesses guiding principles and criteria to enable them to centre their responsibilities around circularity. Extended Producer Responsibility (EPR) laws and regulations are also gaining importance, with governmental and non-governmental organizations making producers accountable for all product life-cycle management.

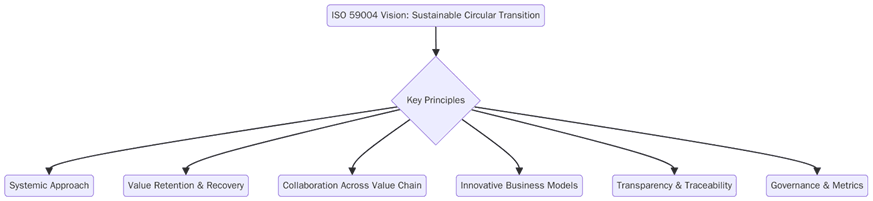

ISO 59004 Principles for Circular Economy Transition

ISO 59004 provides an overreaching set of principles for transitioning to a circular economy. The standard outlines how organizations can redesign their operations and value chains to minimize waste, maximize resource use and upgrade product lifespan. The key principles of ISO 59004 include:

1. Products should be conceived for longevity and be amenable for repair, refurbishment and reuse.

2. Minimizing waste, by maximizing material efficiency so that production has lower environmental impact.

3. Promoting modular designs, to enable repairs and alterations of products, encouraging reuse and recycling.

4. Ensuring that products are not assembled, and recycled or reused at end-of -life so as to minimize landfill.

5. Encouraging renewable, recyclable or biodegradable materials that will continue a circular supply chain.

Product Design Criteria Under ISO 59010

ISO 59010 identifies the criteria for the design of products that meet circular economy principles. Products should be designed for durability and longevity to help prevent them from needing to be replaced. Products should be designed in materials that are recyclable or biodegradable enabling them to be reused or repurposed once their useful life is complete. Products should also be aware of energy use throughout the life of the product, from production to disposal, and select the most energy smooth options possible. Materials should not pose any health risk or environmental concern so that products are not dangerous to health or the environment during any lifecycle phases.

Linking ISO 14025 EPDs with Circular Labels

ISO 14025 provides guidelines for Environmental Product Declarations (EPDs), which are standardized reports that communicate the environmental performance of products. EPDs help businesses measure the environmental impact of their products, including energy use, material consumption and emissions over the product's life cycle

Aspect | ISO 14025 EPDs | Circular Labels | |

Purpose | Communicates the environmental performance of products, including life cycle impact. | Indicates products designed with circular economy principles such as recyclability or durability. | |

Data Provided | Quantifies environmental impacts like carbon footprint, water usage, and emissions. | Displays information on the product’s circularity, such as its recyclability or modularity. | |

Certification | Requires third-party verification of product environmental data. | Labels indicate products meeting specific circularity standards or criteria. | |

Consumer Benefit | Provides transparent, detailed data for eco-conscious consumers. | Makes it easier for consumers to identify products that align with sustainable purchasing preferences. | |

Application | Used for communicating lifecycle impacts for all product categories. | Primarily used to signal products with circularity attributes, enhancing consumer trust. |

Extended Producer Responsibility and ISO Standards

Extended Producer Responsibility (EPR) laws are laws that require producers to take responsibility for the (life cycle and post-consumer...) phase of their products.

Standards like ISO 59000, ISO 14025, and ISO 8000 promote EPR by helping businesses design for products, data management, and sustainability reporting, which ultimately mean they can be compliant with EPR and be aware of their product's waste and impact.

Building systems to collect and recycle products after they have reached the end of their life cycle. Designing products for recycling, reusing materials, and committing to reducing packaging waste. Using standards like ISO 14025 to provide transparent environmental impact data to support EPR initiatives.

For assistance, contact us at [email protected].

ISO 20887 for Sustainable Buildings Assessment

ISO 20887 provides a framework for assessing the sustainability of buildings. As part of the broader push towards sustainability, buildings must be designed and constructed with circular economy principles in mind.

Key features of ISO 20887 include:

• Ensuring that buildings utilize energy smoothly and reduce their carbon footprint and facilitate renewable energy efforts.

• Assessing what materials are used in a building design and assessing their sustainability, recyclability, or biodegradability elements.

• Implementing waste management practices into building design; often buildings have waste during construction and demolition. Provide opportunities for reuse and recycling of the materials in each stage.

• Life cycle assessments can identify the environmental cost of buildings over the course of their life, through demolition and reuse.

Circular Supply Chain Metrics Template

The measurement of supply chain performance is critical to the transition to a circular economy to ensure that resources are utilized, eliminate waste, and to measure sustainability goals. Utilizing a Circular Supply Chain Metrics Template is a valuable way to measure key performance indicators (KPIs) associated with the circular economy.

The amount of raw materials used for every unit of production, which assists in measuring resource efficiency. Supplier sustainability practices, such as if they are utilizing renewable materials or renewable energy. Tracking the average life of products/materials, so that you can understand how much are eligible for reuse or recycling. Also, measuring the waste diverted from the landfill by reuse, recycling or repurposing.

Contact Us

Pacific Certifications can assist your organization in navigating the transition to a circular economy by guiding you through ISO certifications such as ISO 59004, ISO 14025, and ISO 20887. Our team of experts will help you implement sustainable practices, upgrade compliance with EPR laws, and support your journey toward environmental sustainability.

For assistance, contact us at [email protected].

Visit our website at www.pacificcert.com.

FAQs

Q1: What is ISO 59004?

ISO 59004 provides the principles for transitioning to a circular economy, focusing on the design, production, and management of products to maximize resource efficiency and minimize waste.

Q2: How does ISO 14025 relate to circular economy principles?

ISO 14025 helps organizations create Environmental Product Declarations (EPDs) that communicate the environmental performance of products, supporting transparency and sustainability efforts in the circular economy.

Q3: How do EPR laws impact businesses?

Extended Producer Responsibility (EPR) laws hold businesses accountable for the entire lifecycle of their products, from production to disposal. By aligning with standards like ISO 59004, organizations can ensure compliance with these laws and reduce their environmental impact.

Q4: What are the benefits of using ISO 20887 for sustainable buildings?

ISO 20887 provides guidelines for evaluating the sustainability of buildings, ensuring that they are energy-smooth, resource-smooth, and aligned with circular economy principles, reducing their environmental impact over their lifecycle.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs