From Digital Twins to 5G: ISO 23247 & 20140 for Industry 4.0

Industry 4.0 represents the future of manufacturing; digital twins, 5G, smart factories - the production evolution is becoming real. To make that happen, standards like ISO 23247 and ISO 20140 are part of the process. Standards for automation systems, integration and cybersecurity to smart manufacturing.

In this blog we will explore how ISO 23247 and ISO 20140 are being utilized for impending smart manufacturing technologies and initiatives, toward supporting digital transformational initiatives, optimizing industrial automation, or connecting systems with same interface. In addition, looking at some use cases, funding opportunities and how to ensure cybersecurity in Industry 4.0.

For assistance, contact us at [email protected]

Introduction

Industry 4.0 combines digital technologies with manufacturing, including digital twins, Internet of Things (IoT) devices, artificial intelligence (AI), and 5G. Industrial IoT devices collect data in real time and utilize predictive analytics and automated decision-making, and Industry 4.0 will change how products are designed, manufactured, and distributed to people.

Two key standards are ISO 23247 and ISO 20140. ISO 23247 will provide reference architectures for a digital twin and other cyber-physical systems and ISO 23247 will integrate systems regardless of the type of industrial application, as well as clarify cyber-physical system strategies for automated decision-making in complex environments

ISO 23247 reference architecture explained

ISO 23247 describes a reference architecture for digital twins and other cyber-physical systems in relation to Industry 4.0. Digital twins are essentially a non-physical digital representation of a physical asset or system designed to upgrade performance, anticipate maintenance, and simulate changes before they take place in the real world. The ISO 23247 standard gives manufacturing operations a roadmap to pull such virtual models into their operations.

The architecture provides a pathway to integrate the digitized assets via the relevant physical assets, sensors, and data sources to the digital twin model. Thereby allowing incoming and historical sensing and data sources to engage with their peer digital twin in real time. The standard underlines interoperability for heterogeneous systems to work together in the same digital ecosystem, despite using different technologies.

ISO 20140 Automation Systems & Integration: Practical use cases

ISO 20140 focuses on the integration and automation of systems in industrial environments, enabling more smooth operations, improved system performance, and greater flexibility in manufacturing processes.

By following ISO 20140's guidelines, manufacturers can implement automation systems in their production lines, that control production lines, monitor the status of equipment and workflow according to real-time data.

ISO 20140 can also integrate energy monitoring systems with production systems to manage energy usage, waste, and help with sustainability initiatives.

Supporting predictive maintenance approaches through automation systems following ISO 20140 can be completed by monitoring the equipment's performance and notifying operators precisely before it fails.

ISO 20140 promotes automation across all core supply chain systems to optimize product flow, inventory, and supplier interactions to provide the most efficiency across the supply chain.

Time‑sensitive networking and ISO/IEC 8802‑1 time profiles

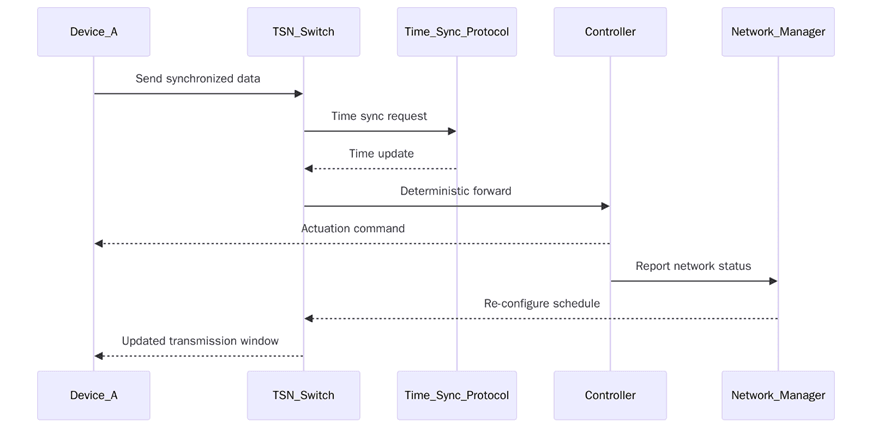

Time-Sensitive Networking (TSN) is an essential technology for Industry 4.0, providing deterministic communication with low-latency and high-reliability across industrial networks. It enables accurate synchronization of all devices on the network, so that critical data flows (and is received) in real time.

By incorporating TSN, ISO/IEC 8802-1 provides for real-time response of critical industrial systems, which is particularly necessary for robotics, machine-to-machine communication, and autonomous systems. The standard facilitates the creation of highly available networks so that downtime does not affect industrial operations, allowing companies to run more continuous operations. ISO/IEC 8802-1 also supports scalable architectures, which allow companies to incrementally deploy TSN-enabled networks as their manufacturing operations grow.

KPI Dashboard template for smart factories

Monitoring key performance indicators (KPIs) is essential for optimizing the performance of smart factories. A KPI Dashboard allows manufacturers to track and visualize real-time data on production efficiency, machine performance, energy usage, and more.

Cyber‑Physical Security: Linking ISO 27019 with ISO 23247

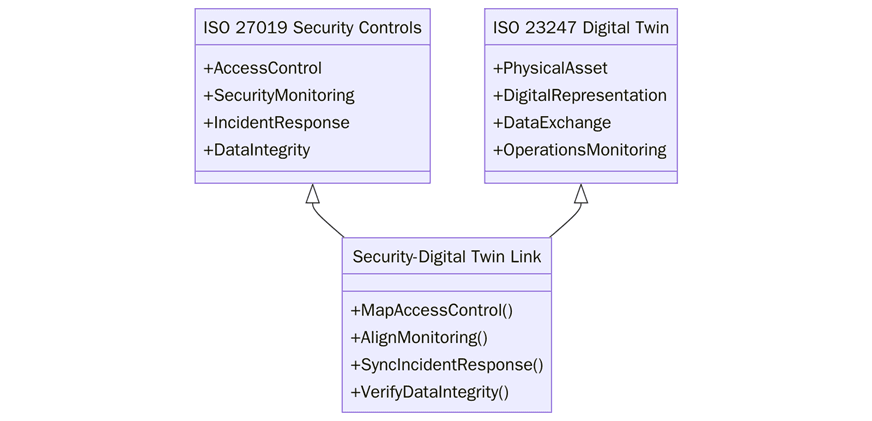

As Industry 4.0 relies heavily on interconnected systems, ensuring the security of cyber-physical systems becomes critical. ISO 27019, which focuses on cybersecurity for energy utilities, can be integrated with ISO 23247 to ensure that both the digital and physical aspects of Industry 4.0 systems are secured against cyber threats.

Key integration points between ISO 27019 and ISO 23247 include:

ISO 27019 contains guidelines for ensuring the confidentiality, integrity, and availability of data which is especially important in the context of data transfer from physical systems to digital systems in Industry 4.0.

Each ISO standard emphasizes restricting access to sensitive information or systems to authorized personnel only; that it is important to prevent unauthorized access to manufacturing systems.

Incorporating ISO 27019 security protocols into an ISO 23247 implementation of digital twins enables manufacturers to quickly identify and respond to cyber threats that could not only interrupt production but threaten safety as well.

Factories should protect data and systems within their supply chain against cyber threats, in accordance with both ISO 27019 and 23247 security guidelines.

For assistance, contact us at [email protected]

Funding Opportunities for Industry 4.0 ISO Alignment in the U.S.

Industry 4.0 opportunities are inherently capital intensive and manufacturers in the U.S. are always looking for sources of funding to help offset the costs of technologies like 5G, digital twins, automation systems, etc. Numerous funding opportunities exist for businesses to adopt Industry 4.0 principles and align with ISO 23247 and ISO 20140.

Government grants for manufacturers for Industry 4.0 technologies include grants enabling the utilization of Industry modernizations, digital technology, and cyber security. There are also several specific regional programs in the U.S. which offer areas of support for businesses adopting Industry 4.0. States have also developed direct funding programs focused on IoT connections, automation, and workforce training programs.

Manufacturers can access tax incentives for R&D engagements, digital product or services, and investments in various sustainable manufacturing technologies. Lastly, private equity or venture capital firms often invest in innovative manufacturing companies and look for ways for these firms to adopt Industry 4.0 practices.

Contact Us

Pacific Certifications can assist your organization in having the adoption of ISO 23247 and ISO 20140 for Industry 4.0, providing guidance on certification processes, implementation strategies, and compliance. Our team of experts will help you integrate cutting-edge technologies into your operations while ensuring that your systems meet global standards.

If you need support with ISO 23247 and ISO 20140 certification, contact us at [email protected].

Read More at: Blogs by Pacific Certifications