ISO 10427-1:2024 – Well Cementing Equipment: Casing Centralizers

Quick Summary

In this post, ISO 10427-1:2024 is introduced as the part of the ISO 10427 series that focuses on casing bow-spring centralizers—key tools in well cementing for oil, gas, and lower-carbon energy sectors. The standard sets specifications for their design, materials, performance testing, installation, and compatibility to ensure these devices consistently center casing and enable uniform cement placement, improving well integrity and zonal isolation. Certification under ISO 10427-1 ensures equipment reliability under harsh downhole conditions, reduces cementing failures and costly rework, supports regulatory compliance, and promotes safer, more efficient operations.

Introduction

ISO 10427-1 is part of ISO 10427, introducing equipment used in well cementing for the oil and gas industry (lower carbon energy applications included). ISO 10427-1 covers casing bow-spring centralizers as well as providing a technical specification for the design, materials, testing and performance of casing bow-spring centralizers for well cementing operations. Casing bow-spring centralizers assist in centre the casing in the well-bore to provide a uniform cement sheath around the casing. This is important for improving the integrity of the wellbore and ensuring zonal isolation is maintained properly.

In this blog piece, we will give an overview of the key points of ISO 10427-1, including the requirements, use, and benefits, and how it impacts the oil and gas industry with respect to well cementing operations.

For assistance, contact us at [email protected].

Well cementing is an essential step in the construction of oil and gas wells. The goal of the cementing process is to downhole cement correctly in the annular space between the wellbore and the casing to provide support to the casing, zonal isolation, and to prevent contamination. Foundation of the issues surrounding well cementing stems directly from things like the irregular shapes of the wellbore and fluid dynamics that make it difficult to obtain quality cement placement.

Casing bow-spring centralizers shall be utilized to mitigate against the challenges associated with cementing. Casing bow-spring centralizers centre casing in the wellbore while cement is being placed in the circumferential area separating the casing and borehole. The centralizers ensure the casing remains stationary which allows for more even distribution of cement, ultimately reducing the likelihood of not obtaining good cement bonding, etc. In other words, the casing bow spring centralizers allow for a better opportunity to avoid channelling or other issues that tend to minimize the integrity of the well itself.

ISO 10427-1 identifies the specifications applicable to casing bow-spring centralizers in the pursuit of establishing how they are going to operate correctly during well cementing.

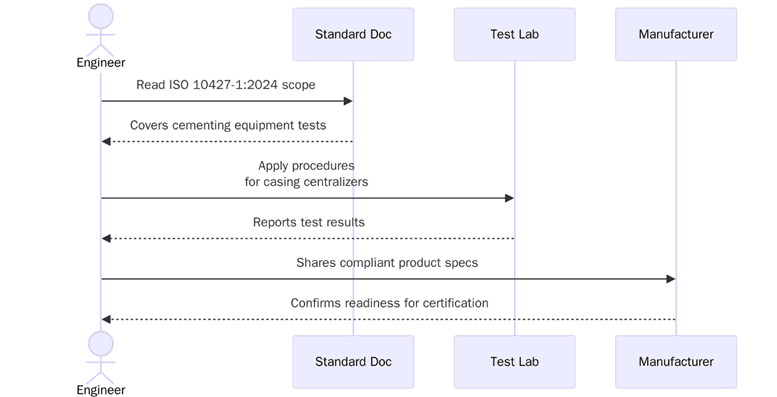

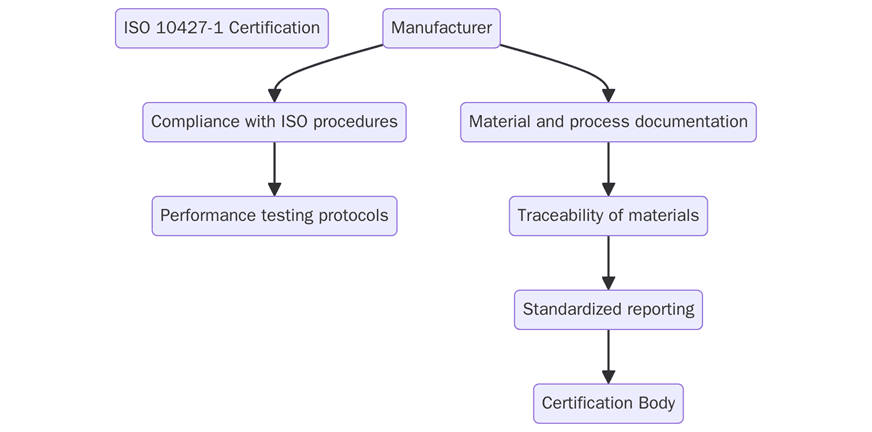

What are the requirements of ISO 10427-1 Certification?

ISO 10427-1 outlines several key requirements that organizations must meet to ensure the effective performance of casing bow-spring centralizers in well cementing operations. These requirements are crucial to ensuring that casing centralizers operate under the demanding conditions of wellbore environments, thus improving well cementing quality and well integrity.

1. This standard establishes guidelines for the design of casing bow-spring centralizers that include material, mechanical properties and dimensions of centralizers. The manufacturer must ensure casing bow-spring centralizers will withstand the conditions imposed during cementing operations which may include high pressure and temperature.

2. ISO 10427-1 establishes material specifications for casing bow-spring centralizers to include strength, durability and resistance to corrosion. Materials must withstand the harsh conditions typically encountered in the oil and gas industry as casing bow-spring centralizers are exposed to high temperatures and aggressive wellbore conditions.

3. The standard identifies the testing requirements for casing bow-spring centralizers to determine mechanical strength, spring deflection, and maintain casing centralization. This testing simulates realistic conditions to provide reliability of the casing bow-spring centralizers used in cementing applications.

4. ISO 10427-1 provides guidance on the proper handling, installation, and deployment of casing bow-spring centralizers. This ensures that they are used effectively during well cementing operations and that the correct procedures are followed to achieve optimal performance.

5. The standard requires that casing bow-spring centralizers be compatible with other well cementing equipment, such as cement plugs and pumps, to ensure smooth integration and operation during cementing.

For assistance, contact us at [email protected]

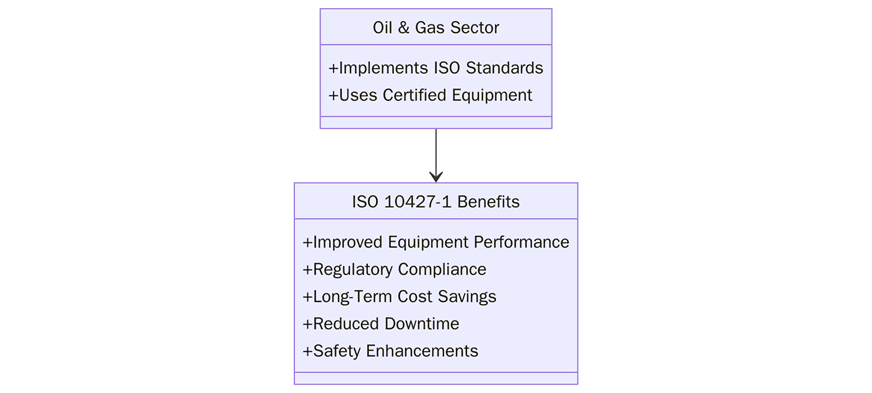

What are the benefits of ISO 10427-1 for the Oil and Gas Industry?

Implementing ISO 10427-1 provides several advantages for organizations involved in well cementing operations. By adhering to the guidelines set forth in ISO 10427-1, companies can see notable improvements in cementing quality, operational smoothness, and cost-effectiveness. These benefits help improve the success of well construction projects:

Proper cement placement is critical for well integrity and mitigation of gas migration and water contamination. ISO 10427-1 ensures casing centralizers provide proper casing centralization, and uniform cement coverage to maximize well integrity and zonal isolation.

ISO 10427-1 helps alleviate cementing failures, which can be costly in terms of time delays and rework. By outlining the performance and design characteristics of the casing centralizers, ISO 10427-1 improves overall efficiencies related to the cementing component of the well.

The reduction of remedial work required and minimized risk of expensive well integrity failures are a result of effective cementing. By ensuring that casing bow-spring centralizers perform consistently, ISO 10427-1 reduces operational costs and upgrades overall long-term cost effectiveness.

The standard ensures that casing bow-spring centralizers comply with specific performance criteria and provides consistency in cementing operations, allowing operators to adopt and rely on a standardized method of well construction to mitigate risks and improve outcome success.

ISO 10427-1 provides organizations with a means of compliance with industry standards and regulations, relating to their well cementing operations. By following the specifications afforded by this standard, organizations can ensure compliance with regulatory requirements regarding well integrity and protection of the environment.

By ensuring proper cement placement and reducing the likelihood of wellbore failures, ISO 10427-1 contributes to safer operations. Well integrity issues can pose significant safety risks, so maintaining a reliable cement sheath is crucial for safeguarding both personnel and the environment.

Contact Us

Pacific Certifications can assist your organization in navigating the ISO 10427-1 certification process. Our team of experts will guide you through the steps of implementing the standard for casing bow-spring centralizers and other well cementing equipment, ensuring compliance with industry standards and improving your operational fluency.

For assistance, contact us at [email protected].

Visit our website at www.pacificcert.com.

Read more: Pacific Blogs