Implementing an Integrated ISO 9001, 14001 & 45001 IMS

In competitive and regulated business environments, the trend of companies adopting Integrated Management Systems (IMS) as a means to streamline processes, cut on costs, and achieve better organizational performance has gained momentum. By integrating ISO 9001-Quality Management, ISO 14001-Environmental Management, and ISO 45001-Occupational Health & Safety Management, a company ensures that all the main areas of its operations are considered and standardized while being subject to continuous improvement.

For assistance, contact us at [email protected].

Introduction

In today's competitive, regulated landscape, Integrated Management Systems are increasingly being adopted by companies to reduce administrative burdens and costs, thus raising performance. In other words, in integrating ISO 9001, Quality Management, ISO 14001, Environmental Management and ISO 45001, Occupational Health & Safety Management systems, the company assures that all major areas of its operations are considered and standardized, subject to continuous improvement.

This blog would highlight how a company can implement integrated ISO 9001, 14001 and 45001 with practical examples in risk management, auditing, and governance, as well as building the culture of quality. Moreover, we shall look at operational efficiencies and cost savings from integration.

Creating a Unified Risk Register Across ISO Standards

A very powerful benefit of an integrated system is putting all the disciplines of risk management under one roof. Instead of having three separate risk registers for ISO 9001, 14001 and 45001, the organization can create one risk register to manage issues concerning quality, environment, and health and safety under one framework.

1. Identifying risks concerning quality (e.g., product defects), environmental impact (e.g., generation of waste) and health and safety (e.g., accidents at the workplace).

2. Evaluating the chances of occurrence and potential level of impact for each identified risk and checking that it is in accordance with the objectives and policies inscribed in the IMS.

3. Determining clear-cut actions to reduce the risk or eliminate any such identified risk, e.g., through improvement of processes, training, or installation of safety devices.

4. Checking, from time to time, whether such actions are implemented effectively and appropriate to the circumstances so that risks can be tackled upon request.

By streamlining risks from the three standards, a company can gain more visibility into risks, improve decision-making and ensure that the risk management goals concerning all areas of their business operation are met.

Management Review Agenda Template for IMS

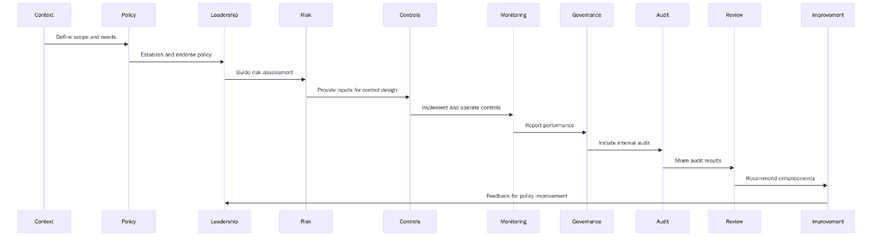

The management review is a critical part of the IMS process, ensuring that top management regularly evaluates the system’s effectiveness and makes decisions to drive improvements. A well-structured Management Review Agenda helps ensure that the review process is overreaching and aligned with the requirements of ISO 9001, ISO 14001, and ISO 45001.

A typical Management Review Agenda for an IMS may include the following:

ISO 37301 Compliance Management: Adding a Governance Layer

ISO 37301 is the international standard for compliance management systems, it allows organizations to build a framework for managing compliance risks, and ensure you are meeting your organizational compliance obligations (current applicable laws, regulations, and obligations set by your organization). By embedding ISO 37301 with ISO 9001, 14001 and 45001, organizations can elevate governance by ensuring compliance is built into all aspects of their operations.

Some of the key benefits from combining ISO 37301 with other standards include:

Establishing a governance framework that incorporates compliance based monitoring, which works to identify regulatory compliance requirements through all aspects of your quality, environmental, and health and safety management systems.

It is always better to identify compliance risks earlier than later so you can have proactive conversations before your risk becomes an issue.

Designing your compliance management system increases transparency in decision making and reporting against the compliance obligations that your organization has accepted as being their responsibilities.

Auditing against compliance obligations as part of your management systems will simplify any internal or external audit process. If compliance is included in the assessment against quality, environmental, and health and safety management systems, you are implementing a overreaching assessment strategy.

For assistance, contact us at [email protected].

Culture of Quality: Linking ISO 30415 Diversity & Inclusion

A solid culture of quality is critical to the success of any IMS and needs to go beyond being compliant with technical standards. An essential part of developing a culture of quality is making sure D&I are part of the organization’s values and practices. ISO 30415 gives guidance on diversity and inclusion for organizations and assists organizations in creating inclusive work environments as a part of their culture of quality.

Encouraging diverse perspectives as part of decision-making processes allows considerations to be taken from different perspectives when planning and implementing the IMS for quality, environment, and health and safety, fostering innovation and continuous improvement contributors. Organizations that have diverse and inclusive workplaces experience significant improvements in employee satisfaction, team effectiveness, and employee ownership in accomplishing quality objectives.

Common Nonconformities in IMS Audits

When conducting an IMS audit, while it is valuable in identifying potential improvements, there are often common, simplistic nonconformities. Engaging in corrective actions, ongoing training, and continuous improvement actions based on a common, simplistic nonconformities make the IMS an effective mechanism to abide by legal requirements and take corrective action.

Missing or incomplete documentation regarding quality, environmental, or health and safety procedures. Lack of evidence providing assurance that the organization is achieving its quality, environmental and health and safety objectives. Gaps in compliance with local, national or international laws, regulations and standards.

Contact Us

If you need support with ISO certifications, contact us at [email protected].

Read More at: Blogs by Pacific Certifications