How to Get ISO 9001 Certified and What Are the Requirements?

Introduction

Quality has become one of the strongest competitive differentiators for organizations across every sector. Institutions today are expected to deliver reliable products, consistent services and predictable outcomes while building trust among customers, suppliers and regulatory bodies. ISO 9001 serves as the world’s most recognized framework for establishing a structured Quality Management System (QMS) that drives consistency and customer satisfaction. It helps organizations clarify responsibilities, evaluate risks, define processes and measure performance in a disciplined, repeatable manner.

Getting ISO 9001 certified is not just about meeting a requirement, it strengthens internal governance, improves transparency and builds a culture where quality becomes a continuous practice rather than a static target. As global markets place higher value on dependable systems and measurable performance, ISO 9001 certification is becoming fundamental for organizations seeking long-term reliability and recognition.

Start your ISO 9001 audit readiness process with Pacific Certifications, an accredited certification body trusted globally.

Quick summary

ISO 9001 sets the requirements for a Quality Management System that focuses on consistent service delivery, risk-based planning, customer satisfaction and continual improvement. Organizations use ISO 9001 to streamline operations, clarify procedures, strengthen leadership accountability and measure quality performance. Certification demonstrates system reliability, builds customer trust and enhances operational discipline across all processes.

Why ISO 9001 certification matters?

Organizations face increasing expectations for quality, traceability and measurable results. ISO 9001 provides a structured system that aligns leadership, processes and monitoring tools to achieve consistent performance. It guides institutions toward greater clarity in roles, responsibility and decision-making.

By implementing ISO 9001, institutions improve communication, reduce errors, strengthen customer confidence and create a culture built on accountability and evidence.

“ISO 9001 transforms quality into an organization-wide commitment, supported by clear processes, reliable controls and measurable results.”

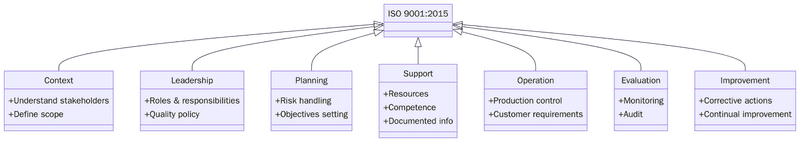

ISO 9001 Core Elements and What They Support?

What are the requirements of ISO 9001 certification?

To achieve ISO 9001 certification, organizations must establish a clear and consistent framework that defines how quality is planned, monitored and improved. A structured QMS ensures that processes are understood, responsibilities are assigned and performance is measurable. Below are the key requirements:

1. Define the scope of the QMS and identify relevant processes.

2. Analyse internal and external issues that influence quality.

3. Establish a quality policy aligned with organizatonal goals.

4. Define measurable quality objectives.

5. Implement risk-based thinking across activities.

6. Maintain documented procedures, process instructions and records.

7. Allocate resources and ensure competence of personnel.

8. Monitor customer satisfaction and feedback.

9. Conduct internal audits to verify performance.

10. Hold management review meetings to evaluate system effectiveness.

11. Implement corrective actions for any issues found.

12. Maintain continual improvement as a sustained practice.

Tip:Build a centralized documentation portal for procedures, changes and evidence to support faster audit readiness and better internal communication.

How to prepare for ISO 9001 certification?

Preparation requires structured planning and a clear understanding of current system maturity. Institutions must document processes, evaluate performance and ensure leadership is actively involved in quality oversight.

Conduct a gap assessment against ISO 9001 requirements.

Update or create QMS documentation such as manuals, procedures and templates.

Define process owners and establish performance indicators.

Provide training to employees on documented procedures.

Implement internal audits to identify issues.

Review findings and complete corrective actions.

Conduct a management review meeting to finalize system readiness.

Certification audit

Stage 1 audit: Evaluates documentation, process descriptions and QMS readiness.

Stage 2 audit: Confirms the implementation of processes, controls and monitoring.

Nonconformities: Must be resolved with evidence before certification.

Management review: Confirms leadership involvement in quality direction.

Final certification: Issued when all requirements are fulfilled.

Surveillance audits: Conducted annually to evaluate sustained performance.

Recertification audits: Required every three years to maintain certification.

What are the benefits of ISO 9001 certification?

Implementing ISO 9001 improves clarity, strengthens accountability and enhances customer confidence. Before these results appear, organizations typically notice improved documentation structure and clearer communication across teams. Below are the key benefits:

Improved consistency in service and product delivery

Increased customer confidence and satisfaction

Better communication and process clarity across departments

Reduced errors, rework and operational inefficiencies

Stronger monitoring through KPIs and performance reviews

Clearer role allocation and documented responsibilities

Better supplier evaluation and procurement reliability

KPIs: defect rate, customer satisfaction index, audit closure cycle

SLAs: complaint resolution time, supplier evaluation cycle, internal audit schedule

Market Trends

Organizations are strengthening their QMS by adopting digital tools, automated dashboards and integrated systems that support data-based decision-making. Cloud-based documentation controls, electronic approval systems and centralized audit tracking platforms are becoming more common. Many institutions are merging with ESG objectives, traceability frameworks and supply chain expectations.

In the coming years, ISO 9001-certified organizations will benefit from AI-enabled monitoring, predictive quality analytics and automated performance measurement tools. Integrating digital quality systems with supplier platforms and customer portals will create more transparent and efficient operations. Institutions that adopt strong QMS structures today will be better prepared for expanded global requirements and quality-driven market expectations.

Training and courses

Pacific Certifications offers accredited training for ISO 9001:

Lead Auditor Training: For individuals performing quality system audits and evaluating compliance.

Lead Implementer Training: For personnel establishing or improving the organization’s Quality Management System.

To schedule ISO 9001 training or awareness programs, contact [email protected].

How Pacific Certifications can help?

Pacific Certifications provides accredited ISO 9001 certification and audit services. Our assessments verify QMS implementation, leadership involvement, documented processes and performance evaluation. We issue Certificates of Conformity after impartial certification audits without offering consultancy services.

For an ISO 9001 certification roadmap, audit plan, or quotation, contact [email protected] or visit www.pacificcert.com.

Contact Us

If you need support with ISO 9001 certification, contact us at [email protected].

Read More at: Blogs by Pacific Certifications