ISO Certifications in Japan, Popular Standards, Requirements and Benefits

Introduction

Japan’s economy spans semiconductors and electronics, precision machinery and automotive, shipbuilding and chemicals, healthcare and laboratories, logistics and a fast-growing SaaS/cloud ecosystem across Tokyo, Kanagawa, Aichi, Osaka, Hiroshima, Fukuoka and Hokkaido. By adopting standards such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health & Safety), companies in Japan can improve efficiency, reduce waste and earn trust from partners and regulators. For expanding areas like ICT, construction advanced manufacturing, ISO certification has become a practical step toward attracting international clients and competing confidently in global markets. These programs provide verifiable assurance on quality, safety, environment, information security and continuity that buyers and lenders accept across APAC, the EU and North America.

Contact Pacific Certifications to confirm your ISO certification scope and proposed Stage 1/Stage 2 audit dates in Japan under recognized accreditation.

Economic Context & Industry Overview

Japan remains one of the world’s most sophisticated industrial and services economies. Electronics, mobility and materials are undergoing reinvestment (including next-gen fab initiatives), while logistics upgrades and construction projects continue across major corridors. Digital government priorities and the broader data-centre/cloud buildout are raising expectations on cybersecurity and service continuity. Across these sectors, procurement teams and regulators increasingly expect auditable management systems for vendor approval, tenders and due diligence.

Why ISO certification matters in Japan?

Tier-one buyers and public authorities require evidence-based systems with clear records. ISO standards give a shared assurance language that shortens vendor approval, stabilizes yield on precision lines, improves site safety and environmental performance, protects data and uptime for digital platforms and demonstrates HACCP-based traceability for food brands. Certification also organizes the evidence, policies, KPIs, competence, risk files and corrective actions, so reviews by customers, regulators and financiers move quickly and predictably.

Popular ISO Standards in Japan

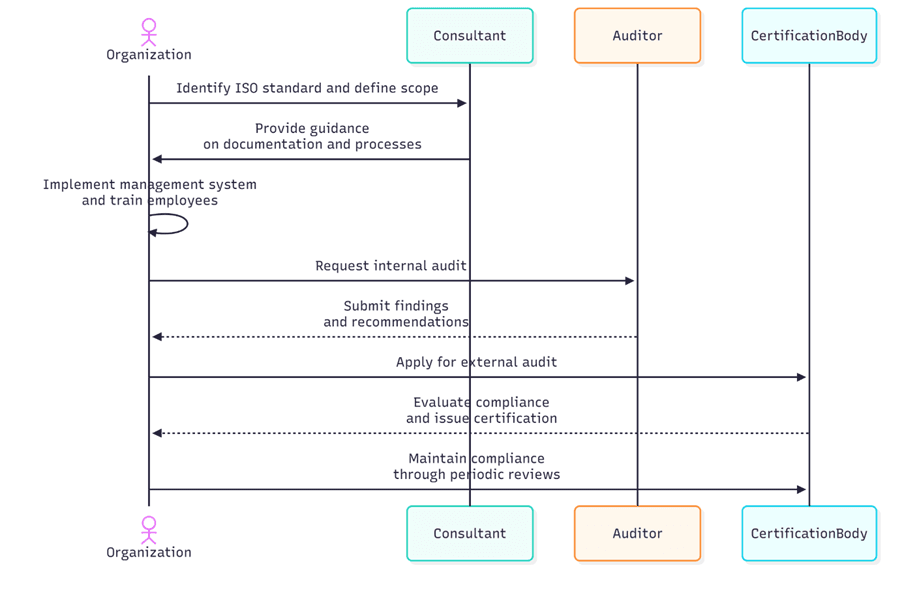

Certification Process in Japan

Preparation starts with an honest view of how work runs today and how evidence is captured. The aim is to make your system auditable without reinventing daily routines. Below are the steps to consider:

List products services sites headcount and high-risk processes for clear scope

Map processes end to end to show handoffs records and responsibilities

Set policy and measurable objectives linked to customer and legal needs

Assemble evidence packs for production maintenance labs IT and logistics

Train process owners keep competence matrices and attendance records current

Calibrate instruments verify methods and file certificates for quick checks

Run internal audits that sample high-risk tasks and supplier interfaces

Hold management review with KPIs audit results complaints legal updates and actions

Schedule Stage 1 for readiness and Stage 2 for implementation verification align multi-site sampling to risk

Blend on-site checks with remote interviews where suitable to reduce travel time

Keep permits licenses and regulatory reports organized for quick verification

What are the requirements of ISO Certifications in Japan?

Build the system around how work actually runs on lines, sites, clinics, warehouses and data rooms and align with Japanese norms so evidence stands up in audits, inspections and buyer reviews; below are the key requirements:

Scope that matches products/services, processes and sites (single or multi-site).

Documented system with controlled procedures and records that match practice.

Risk assessment with controls reflecting real hazards (HACCP, site safety, environmental aspects, privacy/security, energy) and change management.

Competence matrices and training records for process owners and high-risk roles.

Internal audits with reports, nonconformities, root-cause actions and verified closures.

Management review with inputs (KPIs, audits, incidents/complaints, legal updates) and tracked decisions.

Standard-specific artefacts: HACCP & CCP logs (ISO 22000), Statement of Applicability & risk files (ISO/IEC 27001), HIRA & PTW (ISO 45001), aspect-impact registers & objectives (ISO 14001), energy review & EnPIs (ISO 50001).

Legal/other requirements register with permits, inspections, calibrations, monitoring data and supplier compliance evidence.

Tip:Map controls to APPI privacy duties and incident reporting via the PPC, environmental permitting/monitoring and industrial safety expectations; keep calibration certificates, energy/emissions data, cold-chain logs and supplier test reports ready for sampling.

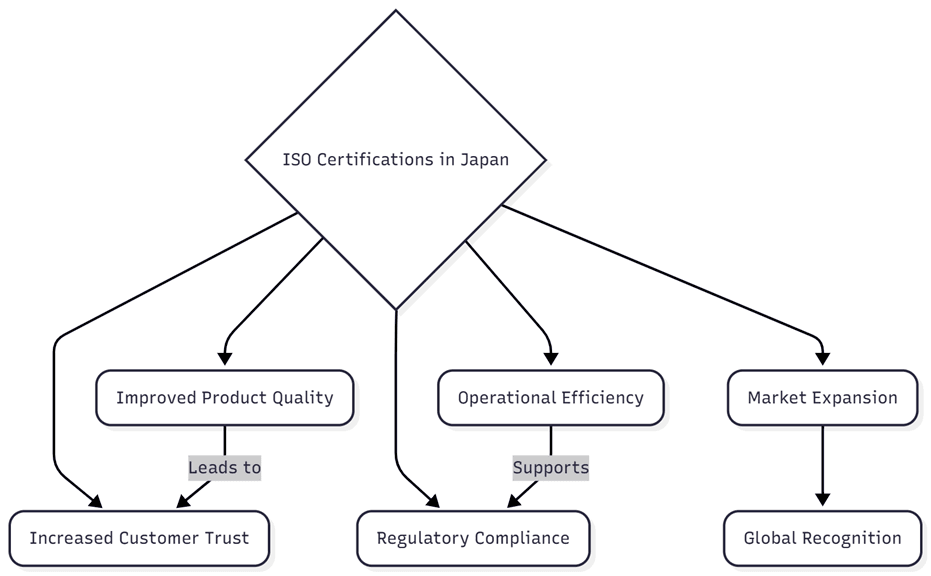

What are the benefits of ISO Certifications in Japan?

Use certification to win vendor status with global OEMs, pass retailer and regulator checks and stabilize operations across shifts and sites; below are the key benefits:

Faster prequalification in buyer portals and public procurement

Fewer incidents, defects and unplanned stoppages on lines and sites

Clear roles and competence paths for critical operations and maintenance

Traceable data for warranty, claims, ESG and due diligence

Better supplier control through audits, KPIs and corrective actions

Measured gains in energy use, waste, emissions, uptime and yield

Stronger brand signals in APAC, EU and US markets

Market Trends

Looking to 2027–2030, two forces are set to pull ISO adoption. Digital society build-out: Japan’s updated Priority Plan for the Realization of a Digital Society points to continued modernization of identity, data exchange and government platforms, pressure that will keep fintech, cloud and public services leaning on ISO/IEC 27001 for security, ISO 22301 for continuity and ISO/IEC 20000-1 for service quality as SLAs harden. Industrial reinvestment in semiconductors: Government support to restore leading-edge capacity (e.g., large-scale subsidies and a national fab program) is catalysing tighter supplier controls across materials, equipment and logistics, reinforcing demand for ISO 9001/14001/45001/50001 and ISO 28000 in the wider ecosystem as new capacity targets the late-2020s. (source: Reuters)

Challenges Faced in Japan

Operational, regulatory and evidence-readiness issues related to getting certified can cause delays, budget constraints and staffing gaps, incomplete or outdated documentation and records, weak internal audits and corrective actions, supplier-control gaps, multi-site sampling and travel logistics, calibration and permit backlogs and data/privacy mapping for ICT; below are the key challenges:

Budgeting for certification time and ongoing system maintenance

Perception of ISO as “compliance” rather than a performance tool in some teams

Shortage of seasoned internal auditors and process owners outside major hubs

Stalling on document control, internal audits and corrective-action discipline

Multi-site and supplier sampling (tiered electronics chains) complicating logistics and evidence quality

What is the cost of certification in Japan?

Certification fees are confirmed after scoping and reflect headcount and risk, the number and spread of sites (e.g., Kanto/Kansai/Chubu/Hokkaido/Kyushu), your standards set (single vs. integrated such as 9001+14001+45001), sector sampling depth (precision lines and cleanrooms vs. offices) and travel/logistics. Your proposal itemizes Stage 1, Stage 2 and surveillance days, clarifies on-site versus remote activities and highlights any multi-site efficiencies so budgets remain transparent and predictable.

For personalized quote, contact [email protected].

What is the timeline for certification in Japan?

Timelines depend on document and record readiness, the speed of closing any Stage-1 findings, whether you are single- or multi-site and whether the program is single-standard or integrated. Coordinating audit windows around shutdowns, production ramps, or release cycles and auditor travel to regional sites, also affects duration. A well-prepared single site can progress from application to decision within one audit cycle; multi-site or integrated programs typically require additional planning and sampling time.

How Pacific Certifications can help?

Pacific Certifications audits and certifies ISO management systems for electronics and semiconductors, automotive and machinery, chemicals and materials, logistics and ports, healthcare and SaaS/cloud across Japan. We work under recognized accreditation with transparent pricing and an experienced local team that understands site realities and buyer expectations. Our certificates are accepted by procurement portals and international customers and we are recognized by ABIS.

Request your ISO audit plan and fee estimate. We will help you map Stage 1 and Stage 2 timelines and evidence requirements for your organization. Contact us at [email protected] or visit www.pacificcert.com.

Accredited Training Programs

Pacific Certifications provides accredited training programs in Japan for ISO 9001, ISO 14001, ISO 45001, ISO 22000/FSSC 22000, ISO/IEC 27001, ISO 22301 and ISO/IEC 20000-1.

Lead Auditor Training: for professionals auditing these systems across Japanese industries.

Lead Implementer Training: for personnel establishing or improving systems in plants, sites, cold chains, hospitals, utilities and ICT platforms.

These programs are conducted online or onsite, depending on client needs under ISO/IEC 17024 for personnel certification.

Contact Us

For ISO certifications in Japan, contact [email protected]or call +91-8595603096.

Author: Sony

Read More at: Blogs by Pacific Certifications