ISO Certifications for Wooden Furniture Manufacturing Businesses, Requirements and Benefits

Quick Summary

"Wooden furniture manufacturers benefit significantly from ISO certifications that enhance quality, sustainability, safety, and operational efficiency. ISO 9001 ensures consistent, customer-focused production. ISO 14001 promotes environmentally responsible operations through efficient resource use and waste reduction. ISO 45001 safeguards worker health in environments with machinery and airborne dust. ISO 28000 improves supply chain security and material integrity—especially important for sustainable sourcing. ISO 50001 helps streamline energy consumption in production facilities. ISO 38200 validates that the wood used comes from legal, ethical, and sustainable sources. Achieving these certifications involves documented systems, audits, and performance monitoring. The benefits include enhanced product quality, stronger eco-credentials, safer workplaces, greater market access, and increased customer trust—positioning manufacturers for long-term success."

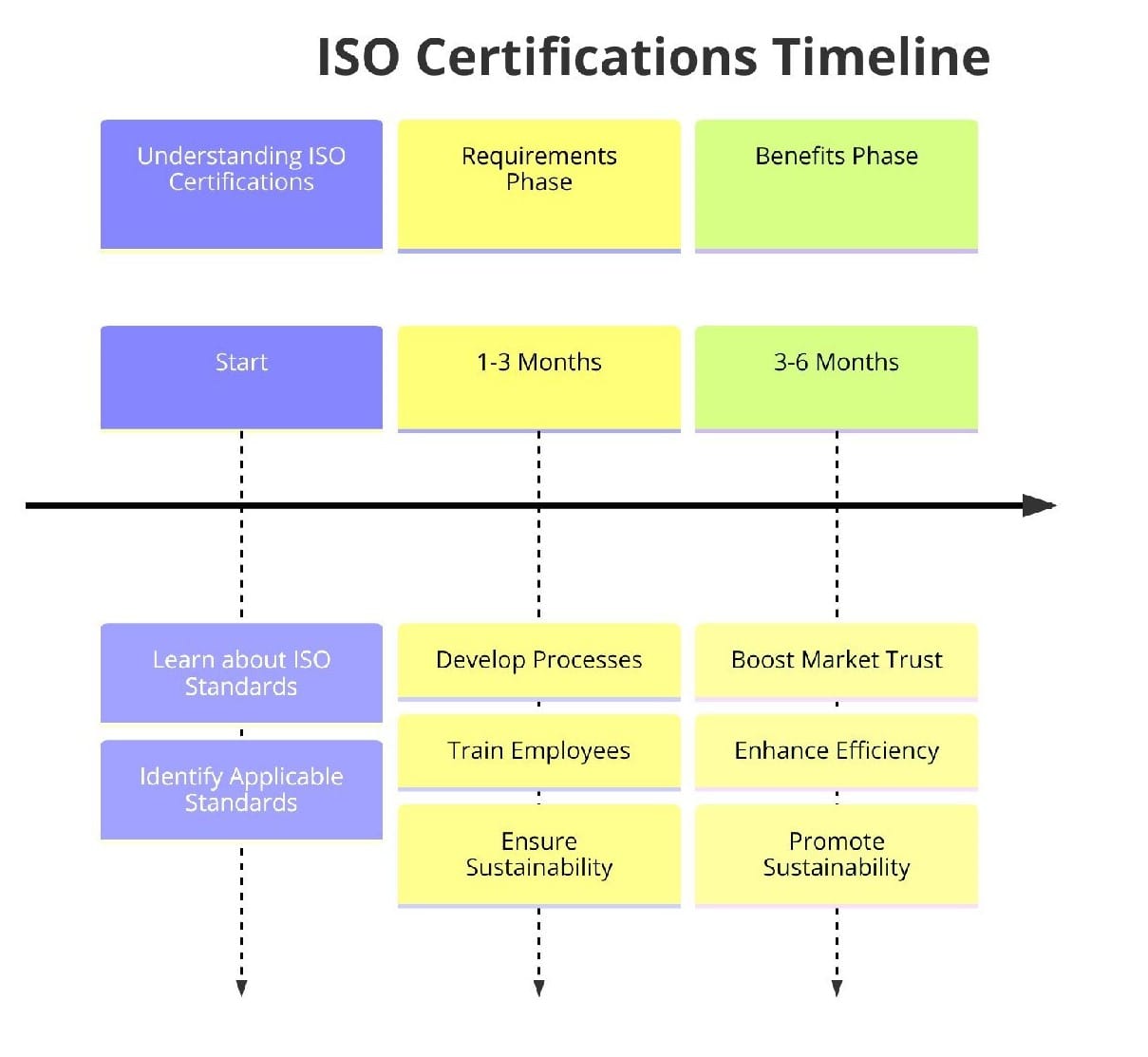

Introduction to ISO Standards for Wooden Furniture Manufacturing

ISO certifications provide a structured framework for companies to meet global quality, environmental, and safety standards. These certifications not only enhance a manufacturer’s reputation but also improve operational efficiency.

ISO certifications are internationally recognized standards developed to improve quality and sustainability. For wooden furniture manufacturing, ISO certifications help businesses streamline their processes, ensure product consistency, and minimize environmental impact.

ISO certifications assure customers that a manufacturer adheres to stringent standards, ensuring trust and long-term relationships.

If you're seeking ISO certification for wooden furniture manufacturing, reach out to us at [email protected] or call +91-8595603096 for expert assistance.

Applicable ISO Standards for Wooden Furniture Manufacturing

Several ISO standards are applicable to wooden furniture manufacturing. Each addresses specific aspects of production, safety, quality, and environmental management.

ISO 9001: Quality Management Systems

ISO 9001 focuses on quality management by emphasizing customer satisfaction, process efficiency, and continual improvement. For furniture manufacturers, it ensures that products meet customer expectations consistently.

ISO 14001: Environmental Management Systems

ISO 14001 promotes environmentally responsible practices. This standard is essential for wooden furniture manufacturers, as it encourages sustainable sourcing, waste reduction, and compliance with environmental laws.

ISO 45001: Occupational Health and Safety Management Systems

This standard ensures the health and safety of workers in manufacturing units. Wooden furniture manufacturing involves risks such as exposure to dust, heavy machinery, and chemicals, making ISO 45001 crucial for ensuring workplace safety.

ISO 28000: Supply Chain Security Management Systems

ISO 28000 enhances supply chain security and ensures the integrity of raw materials, especially in industries like furniture manufacturing, where sustainable wood sourcing is vital.

ISO 50001: Energy Management Systems

ISO 50001 helps organizations optimize energy use. For wooden furniture manufacturers, this is particularly relevant to minimize energy costs associated with machinery and production.

ISO 38200: Chain of Custody of Wood Products

This standard ensures that wood used in furniture manufacturing comes from sustainable sources, supporting legal compliance and ethical business practices.

Click here to find out more applicable standards to your industry

Ensure quality and compliance with ISO certifications. Contact us today at [email protected] or dial +91-8595603096 to get started.

At Pacific Certifications, we specialize in providing auditing and certification services to ensure your wooden furniture manufacturing processes meet ISO standards. Our experienced auditors conduct detailed assessments to confirm compliance and issue relevant certifications.

We simplify the certification journey by offering transparent, efficient, and impartial services. With Pacific Certifications, you gain credibility, competitive advantage, and customer trust.

Take the next step towards ISO certification for your wooden furniture business. Email us at [email protected] or call +91-8595603096 now.

Requirements of ISO Certifications for Wooden Furniture Manufacturing

To obtain ISO certifications, wooden furniture manufacturers must meet specific requirements outlined in each standard:

For ISO 9001:

- Implementation of a quality management system (QMS).

- Regularly monitoring and reviewing production processes.

- Focusing on customer satisfaction and feedback.

For ISO 14001:

- Identifying environmental impacts of operations.

- Setting measurable environmental objectives.

- Adhering to laws regarding emissions, waste disposal, and resource use.

For ISO 45001:

- Developing health and safety protocols for workers.

- Conducting regular risk assessments in manufacturing units.

- Providing training to ensure a safe working environment.

For ISO 28000:

- Establishing secure and traceable supply chains.

- Monitoring suppliers to ensure raw material integrity.

- Regular audits of supply chain processes.

For ISO 50001:

- Conducting energy audits to identify savings opportunities.

- Monitoring energy consumption and reducing waste.

For ISO 38200:

- Verifying the legality and sustainability of wood sourcing.

- Maintaining records of suppliers and raw materials.

Compliance with these requirements ensures your business aligns with industry best practices while addressing customer expectations.

Looking for ISO certification for wooden furniture manufacturing? We're here to help. Reach us at [email protected] or +91-8595603096.

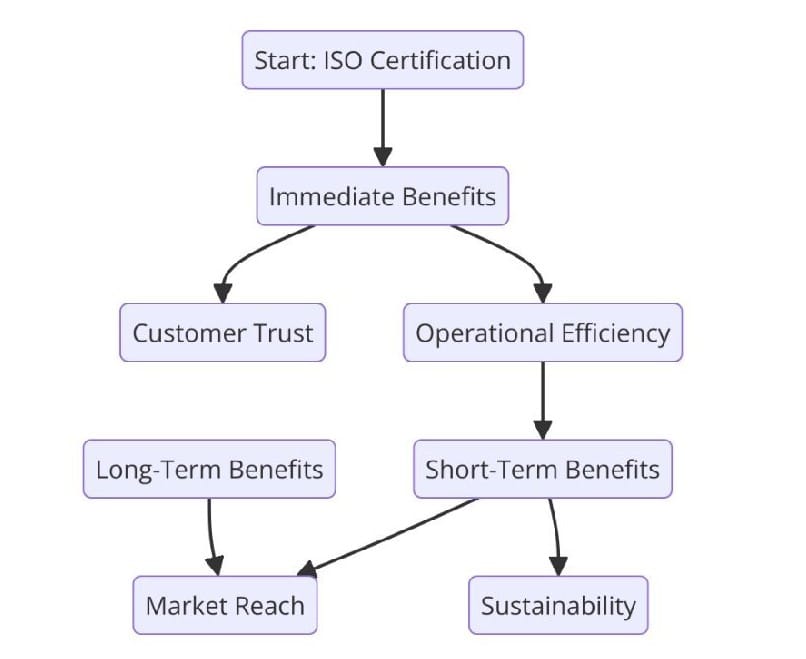

Benefits of ISO Certifications for Wooden Furniture Manufacturing

ISO certifications provide a wide range of benefits for wooden furniture manufacturers:

- Enhanced Product Quality: By adhering to ISO standards, manufacturers ensure consistent quality, reducing defects and complaints.

- Improved Environmental Responsibility: Implementing ISO 14001 and ISO 38200 demonstrates a commitment to sustainable practices, which is increasingly valued by consumers.

- Increased Safety and Compliance: ISO 45001 ensures worker safety, reducing accidents and boosting productivity.

- Operational Efficiency: Standardized processes under ISO certifications enhance efficiency, reducing waste and production costs.

- Competitive Advantage: ISO certifications serve as a mark of trust and reliability, helping manufacturers stand out in a crowded market.

- Market Expansion: Compliance with international standards opens doors to global markets, ensuring regulatory acceptance and customer confidence.

- Customer Satisfaction: ISO standards emphasize meeting customer needs and expectations, building stronger relationships and repeat business.

Achieve ISO certification effortlessly! Contact Pacific Certifications at [email protected] or give us a call at +91-8595603096 today.

In 2024, sustainability continues to dominate the wooden furniture market. A report by industry analysts highlights that 65% of consumers prioritize environmentally friendly products, pushing manufacturers to adopt ISO 14001 and ISO 38200. Furthermore, automation and digital monitoring are transforming quality management under ISO 9001, enabling real-time oversight and swift improvements.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Wooden Furniture Manufacturing business, please contact us at [email protected] or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs