ISO Certifications for the Textile and Apparel Industry: Quality, Sustainability and Compliance

The textile and apparel industry is one of the world’s largest employers, but also one of the biggest polluters. According to the United Nations Environment Programme (UNEP), it generates 92 million tons of textile waste annually and accounts for 10% of global carbon emissions. At the same time, global buyers like H&M, Zara and Nike now demand certified suppliers to ensure product quality, sustainability and fair labour practices.

ISO certifications provide manufacturers, suppliers and brands with internationally recognized frameworks to improve quality, cut waste, protect workers and secure market access. For an industry under constant scrutiny, ISO certification is no longer optional - it is a baseline requirement for global competitiveness.

Start your ISO certification journey with Pacific Certifications and strengthen compliance across your textile and apparel operations.

Quick summary

"ISO certifications help textile and apparel manufacturers reduce defects, manage environmental impact and ensure worker safety and social accountability. The most relevant standards include ISO 9001 certification for textile industry, ISO 14001 sustainability certifications for apparel manufacturers, ISO 45001 for worker safety and SA 8000 for garment factories. Together, they ensure compliance with global buyer requirements and ESG standards, while delivering measurable improvements in quality, sustainability and market access."

What is ISO certification for textiles and apparel?

ISO certification verifies that a manufacturer, supplier, or brand follows globally recognized management systems for quality, environment, safety and labour practices. Unlike national regulations, ISO standards are internationally accepted and directly support supplier approval by global buyers. For garment factories and mills, certification provides structured governance and evidence that processes meet both regulatory and market expectations.

Why it matters: market and sustainability drivers

1. The textile sector contributes 10% of global carbon emissions (UNEP).

2. Mills and factories certified to ISO 14001 report 20–30% reductions in waste and emissions.

3. ISO 45001-certified factories see up to 30% fewer workplace incidents.

4. Over 60% of EU importers require ISO or SA 8000 certification for suppliers (European Commission study).

5. Certified suppliers are 50% more likely to win contracts with EU/US buyers.

With ESG audits, digital traceability and circular economy pressures rising in 2025, ISO certification is becoming a strategic differentiator as well as a compliance requirement.

Relevant ISO standards for textile and apparel

Standard | Focus area | Application in textiles & apparel | Example evidence | Useful KPIs / SLAs |

Quality management | Fabric quality, inspections, stitching accuracy | Quality manuals, NCR logs, inspection reports | Defect rate, right-first-time % | |

Environmental management | Dyeing, effluent control, waste reduction | EMP, water monitoring, emissions logs | Water reuse %, emissions per ton, waste diversion rate | |

Health & safety | Worker safety, machine operation, PPE | Risk assessments, incident reports, toolbox talks | TRIR, accident frequency rate | |

SA 8000 | Social accountability | Labor rights, fair wages, working hours | Payroll records, HR policies, grievance logs | Supplier SLA compliance, audit closure rate |

Energy management | Energy-intensive spinning, weaving, dyeing | Energy audits, consumption logs | Energy intensity per ton, annual improvement rate |

What are the requirements for ISO certification in textile and apparel?

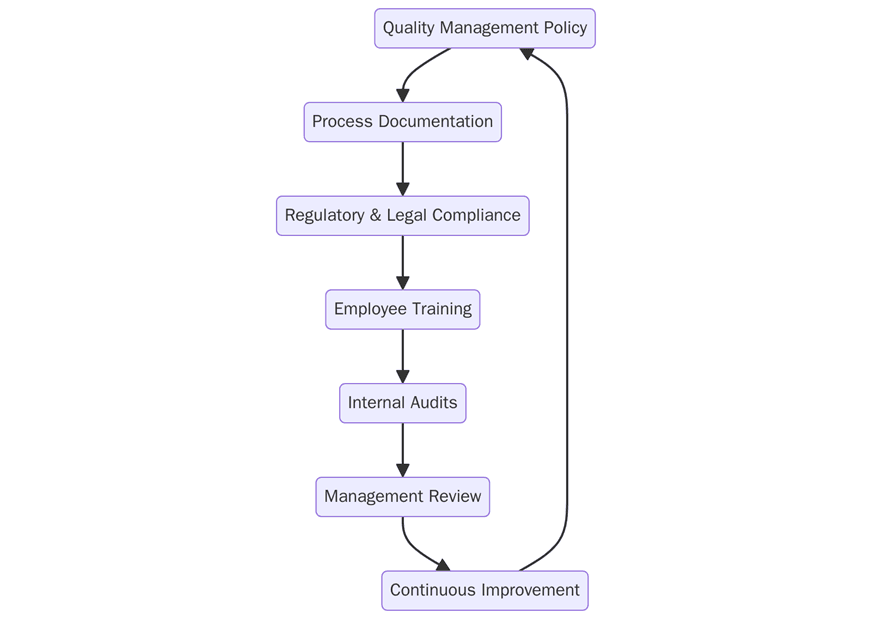

To qualify, manufacturers and suppliers must demonstrate that quality, environmental and social governance systems are documented, monitored and continually improved. Key requirements include:

1. Define scope (e.g., factories, mills, dye houses, supply chain)

2. Publish policies on quality, environment, health & safety and social accountability

3. Conduct risk assessments for defects, emissions and labour risks

4. Document processes for production, inspection, packaging and logistics

5. Maintain evidence: test reports, monitoring logs, payroll data, training records

6. Train staff on quality checks, safety rules and compliance responsibilities

7. Run internal audits and close nonconformities before external certification

8. Review performance through KPIs, SLAs and management oversight

What are the benefits of ISO certification in textile and apparel?

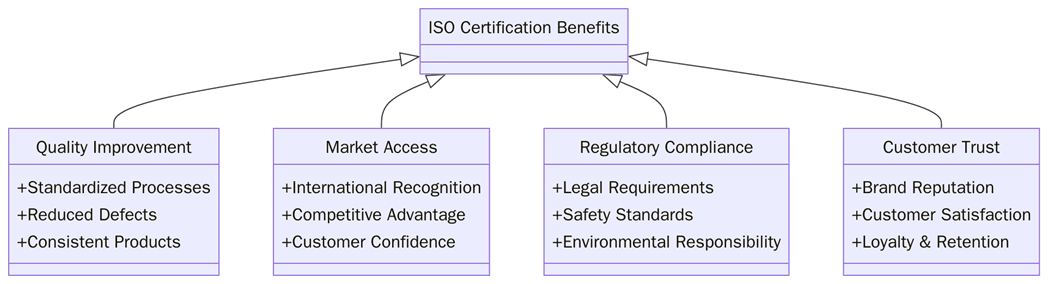

ISO certifications deliver measurable outcomes that go beyond compliance.

1. Quality improvement: ISO 9001 reduces defect rates by up to 40%, lowering returns and rework.

2. Sustainability: ISO 14001 certified mills cut water use by 25% and emissions by up to 30%.

3. Safety: ISO 45001 reduces workplace incidents by around 30% compared to non-certified factories.

4. Market access: Certified suppliers are 50% more likely to win international contracts.

Textile and apparel institutions are adopting integrated management systems that combine ISO 9001, ISO 14001, ISO 45001 and SA 8000 under one framework. Digital traceability is emerging as a top trend, with buyers demanding QR-coded product histories that align with ISO standards. Circular economy practices such as textile recycling and closed-loop production are also being linked to ISO 14001 certification. Institutions are tracking KPIs like water reuse %, emissions per ton, accident response times and supplier SLA compliance to prove improvements during ESG audits.

How Pacific Certifications can help?

Pacific Certifications provides accredited ISO certification services for textile and apparel manufacturers, suppliers and brands. Our independent audits help demonstrate compliance, strengthen governance and support buyer approval processes worldwide.

Request your ISO audit plan and fee estimate, we will help you map Stage 1 and Stage 2 timelines and evidence requirements for your facilities. Contact us at [email protected] or visit www.pacificcert.com.

Summary

ISO certifications in textiles and apparel help manufacturers, suppliers and brands meet global buyer expectations on quality, sustainability and social accountability. By adopting standards like ISO 9001, ISO 14001, ISO 45001, ISO 50001 and SA 8000, institutions can reduce defects, improve safety, cut environmental impact and strengthen worker welfare. With consumer and regulatory scrutiny increasing in 2025, ISO certification is becoming a baseline requirement for international buyers and a key driver of competitiveness in the global fashion industry.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs

Author's name: Alina Ansari