ISO Certifications for Synthetic Rubber Manufacturing Businesses, Requirements and Benefits

Introduction to ISO Standards for Synthetic Rubber Manufacturing

Ensuring quality, safety, and efficiency in synthetic rubber manufacturing requires strict adherence to internationally recognized standards. The ISO certifications for synthetic rubber manufacturing play a pivotal role in streamlining processes, meeting regulatory requirements, and fostering trust in the global market.

Synthetic rubber manufacturing is a critical industry, contributing to products ranging from automotive tires to industrial gaskets. To ensure the highest quality and environmental sustainability, manufacturers turn to ISO (International Organization for Standardization) standards.

ISO standards provide comprehensive frameworks to manage quality, minimize environmental impact, and enhance operational efficiency. For synthetic rubber manufacturers, these certifications are not just about compliance—they’re a commitment to excellence and customer satisfaction.

Whether addressing material consistency, production techniques, or waste management, ISO certifications ensure that manufacturers meet global benchmarks. This is particularly important as industries face rising demands for sustainable and high-performance rubber products.

If you're seeking ISO certification for synthetic rubber manufacturing, our team at Pacific Certifications is here to guide you. Contact us at [email protected] or call +91-8595603096 for expert assistance.

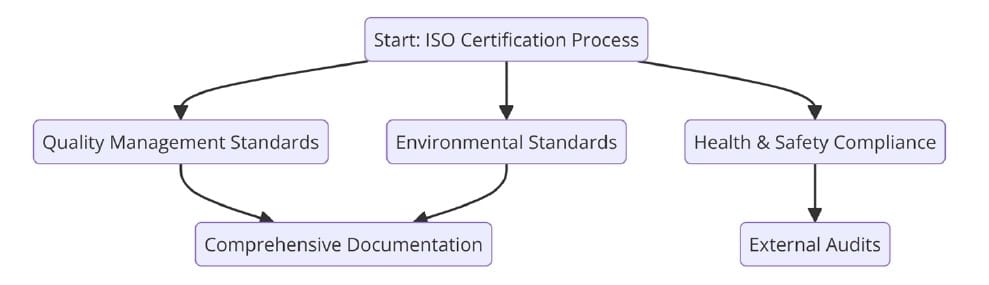

Applicable ISO Standards for Synthetic Rubber Manufacturing

Several ISO standards apply directly or indirectly to synthetic rubber manufacturing, addressing various facets of production, quality control, and sustainability. Key certifications include:

ISO 9001: Quality Management Systems

- Focuses on improving process efficiency and product quality.

- Helps manufacturers deliver consistent products that meet customer and regulatory requirements.

ISO 14001: Environmental Management Systems

- Ensures sustainable practices in managing environmental impact.

- Aids manufacturers in controlling emissions, reducing waste, and conserving resources.

ISO 45001: Occupational Health and Safety Management Systems

- Prioritizes workplace safety by reducing risks associated with manufacturing.

- Focuses on the well-being of employees in potentially hazardous environments.

ISO 50001: Energy Management Systems

- Supports energy efficiency improvements in manufacturing processes.

- Reduces energy consumption and operational costs, aligning with global energy sustainability goals.

ISO 17025: Competence of Testing and Calibration Laboratories

- Relevant for synthetic rubber testing laboratories.

- Ensures accurate testing and analysis of rubber properties.

ISO 26000: Social Responsibility

- Provides guidance on integrating ethical and sustainable practices.

- Encourages manufacturers to balance profitability with social and environmental stewardship.

ISO 15223-1: Symbols for Medical Device Labeling

- Applicable when synthetic rubber is used in medical devices.

- Assures compliance with labeling and usage standards.

By implementing these standards, manufacturers ensure a well-rounded approach to quality, safety, and sustainability.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in providing certification services tailored to your needs. As a globally recognized certification body, we guide organizations through auditing and certification processes, ensuring compliance with the relevant ISO standards.

Our dedicated team ensures that the certification process is seamless, transparent, and aligned with your operational goals. From initial audits to issuing certifications, Pacific Certifications is your partner in achieving excellence.

For seamless ISO certification tailored to synthetic rubber manufacturing, connect with Pacific Certifications. Email us at [email protected] or call +91-8595603096 today.

Requirements of ISO Certifications for Synthetic Rubber Manufacturing

Each ISO standard sets out specific requirements tailored to improve various aspects of synthetic rubber manufacturing. Below is a breakdown of the essential requirements for each relevant standard:

ISO 9001: Quality Management Systems Requirements

Focus: Quality, consistency, and customer satisfaction.

- Establishment of a Quality Policy: Define a quality policy that aligns with organizational goals and meets customer requirements.

- Documented Processes: Maintain detailed documentation of manufacturing processes, quality objectives, and procedures.

- Customer Focus: Incorporate mechanisms to understand and fulfill customer expectations consistently.

- Risk-Based Thinking: Identify potential risks and opportunities to ensure stable production and delivery.

- Internal Audits: Conduct regular internal audits to ensure the quality management system's effectiveness.

- Performance Measurement: Monitor and measure process performance through KPIs (Key Performance Indicators).

- Continuous Improvement: Implement corrective actions and continuously seek opportunities for process enhancement.

ISO 14001: Environmental Management Systems Requirements

Focus: Sustainability and minimizing environmental impact.

- Environmental Policy: Develop a policy demonstrating commitment to sustainable practices.

- Environmental Impact Assessment: Identify and assess environmental aspects, such as emissions, waste, and resource usage.

- Compliance Obligations: Ensure adherence to all applicable environmental laws and regulations.

- Objectives and Targets: Set measurable goals for reducing environmental impact, such as waste reduction and energy efficiency.

- Lifecycle Perspective: Consider the environmental impact of products and processes from raw material acquisition to disposal.

- Operational Controls: Establish controls to manage significant environmental aspects effectively.

- Emergency Preparedness: Develop response plans for potential environmental incidents.

ISO 45001: Occupational Health and Safety Management Systems Requirements

Focus: Workplace safety and employee health.

- Hazard Identification and Risk Assessment: Identify potential workplace hazards and evaluate associated risks.

- Legal and Regulatory Compliance: Ensure compliance with occupational health and safety laws and standards.

- Employee Participation: Involve employees in safety decision-making processes, such as hazard reporting.

- Training and Awareness: Provide health and safety training tailored to employee roles and responsibilities.

- Incident Reporting and Investigation: Create a system for reporting, investigating, and addressing workplace incidents.

- Emergency Preparedness: Establish plans to manage workplace emergencies effectively.

- Monitoring and Improvement: Regularly evaluate safety performance and implement corrective actions as needed.

ISO 50001: Energy Management Systems Requirements

Focus: Efficient energy use and reduction of energy costs.

- Energy Policy: Develop a policy that outlines the organization's commitment to energy efficiency.

- Energy Review: Conduct an energy review to identify significant energy uses and areas for improvement.

- Energy Baseline: Establish a baseline to measure energy performance improvements over time.

- Objectives and Targets: Set measurable energy efficiency goals aligned with business priorities.

- Action Plans: Develop and implement action plans to achieve energy performance objectives.

- Monitoring and Measurement: Use meters and tracking tools to monitor energy consumption and performance.

- Regular Audits: Perform energy audits to identify inefficiencies and opportunities for savings.

ISO 17025: Competence of Testing and Calibration Laboratories Requirements

Focus: Accuracy and reliability of testing for synthetic rubber properties.

- Competence: Ensure laboratory personnel have the required skills and qualifications.

- Calibration and Validation: Maintain calibrated equipment and validate testing methods.

- Quality Assurance: Implement quality control measures to verify the reliability of test results.

- Document Control: Maintain detailed records of all testing procedures and results.

- Customer Communication: Provide clear and detailed test reports to clients, ensuring transparency.

- Impartiality: Ensure independence in testing to maintain credibility.

ISO 26000: Social Responsibility Guidance Requirements

Focus: Ethical and sustainable business practices.

- Organizational Governance: Ensure decisions align with ethical and sustainable principles.

- Human Rights: Respect and promote human rights throughout the supply chain.

- Labor Practices: Provide fair working conditions and opportunities for employee development.

- Community Involvement: Engage with local communities and support development initiatives.

- Environmental Responsibility: Adopt practices that reduce harm to the environment.

- Transparency: Communicate openly about the organization's social and environmental performance.

ISO 15223-1: Medical Device Labeling Requirements (if applicable)

Focus: Proper labeling of synthetic rubber used in medical devices.

- Symbol Usage: Use standardized symbols to convey information clearly.

- Risk Information: Include details about potential risks associated with the material.

- Compliance: Ensure labels meet regulatory requirements in target markets.

- Traceability: Provide batch numbers or unique identifiers for product traceability.

General Requirements Across All Standards

Some common themes run through all ISO standards, including:

- Leadership Commitment: Top management must demonstrate leadership and commitment to the implementation and maintenance of the standard.

- Training and Awareness: Employees must be adequately trained and aware of their roles in meeting ISO requirements.

- Documentation and Record Keeping: Maintain detailed records to demonstrate compliance and facilitate audits.

- Internal Audits and Reviews: Conduct regular reviews to ensure the effectiveness of implemented systems.

- Corrective Actions: Establish a framework to address non-conformities and implement corrective measures.

By meeting these requirements, synthetic rubber manufacturers can build robust systems that ensure compliance, enhance efficiency, and align with global market demands.

Need certification for synthetic rubber manufacturing? Let Pacific Certifications help! Contact us via [email protected] or call +91-8595603096 for more information.

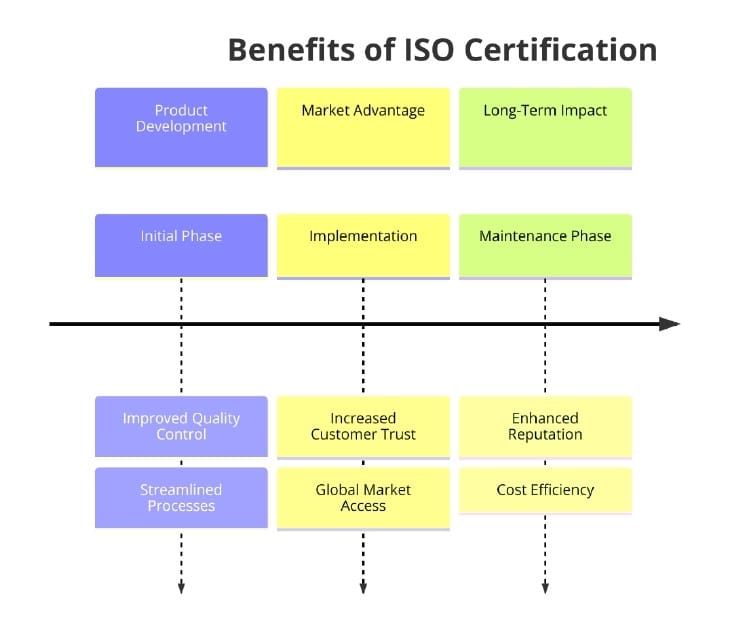

Benefits of ISO Certifications for Synthetic Rubber Manufacturing

The advantages of adopting ISO certifications go beyond compliance. They provide tangible and intangible benefits that enhance the entire manufacturing process:

Enhanced Product Quality: ISO standards focus on consistency, ensuring that synthetic rubber products meet global quality benchmarks.

Regulatory Compliance: Certifications demonstrate compliance with international and local laws, reducing the risk of penalties.

Improved Operational Efficiency: Streamlined processes, waste reduction, and energy efficiency directly impact profitability.

Increased Market Credibility: ISO certifications enhance brand reputation, making it easier to secure global clients and partners.

Employee Well-Being: ISO 45001 ensures a safer work environment, improving employee morale and reducing absenteeism.

Environmental Sustainability: ISO 14001 and ISO 50001 support sustainable practices, aligning businesses with modern eco-conscious consumer expectations.

Whether it’s ISO 9001, 14001, or others, Pacific Certifications is your trusted partner for synthetic rubber manufacturing. Email us at [email protected] or call +91-8595603096 now.

Market Trends

As of 2025, the synthetic rubber industry is undergoing rapid changes driven by technology and sustainability. Manufacturers are increasingly leveraging ISO standards to address the demand for bio-based rubber and eco-friendly production methods.

Reports indicate a surge in the adoption of ISO 14001 and ISO 50001, as companies aim to meet strict environmental regulations. Moreover, advancements in testing technologies are bolstering the importance of ISO 17025.

Conclusion

Ready to elevate your synthetic rubber manufacturing process? Achieve operational excellence and global recognition with ISO certifications. At Pacific Certifications, we’re committed to helping you unlock the full potential of ISO standards. Contact us at [email protected] to get started today.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Synthetic Rubber Manufacturing business, please contact us at [email protected] or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs