ISO Certifications for Structural Metal Product Manufacturing Businesses, Requirements and Benefits

Quick Summary

"Structural metal product manufacturers—producing components like bridges, frames, pipelines, and more—can greatly benefit from ISO certifications that reinforce quality, safety, environmental responsibility, and energy efficiency. ISO 9001 establishes dependable quality management. ISO 14001 supports sustainable practices and waste reduction. ISO 45001 ensures occupational health and safety. ISO 3834 governs welding process quality and personnel competence. ISO 1090 applies specifically to the execution of steel and aluminium structures. ISO 50001 provides a framework for energy optimization. Meeting these certifications involves formalizing policies, documenting procedures, conducting internal audits, and undergoing external assessments. The rewards include enhanced quality control, global market access, safer workplaces, reduced environmental footprint, energy savings, and strengthened customer trust—positioning manufacturers for competitive advantage and alignment with ESG goals."

Introduction to ISO Standards for Structural Metal Product Manufacturing

Ensuring quality and sustainability in structural metal product manufacturing is essential for modern industries. The structural metal product manufacturing industry demands precision and quality. ISO certifications provide an internationally recognized framework to maintain these standards.

ISO (International Organization for Standardization) develops standards that ensure quality management, environmental sustainability, safety protocols, and product reliability. For manufacturers of metal structures, these certifications are vital in meeting regulatory demands and building customer trust.

Why ISO Certifications Matter

ISO certifications demonstrate a company’s commitment to quality and safety. They also assure stakeholders, regulators, and customers that the manufacturing processes align with global standards and inefficiencies.

If you are looking for ISO certification for Structural Metal Product Manufacturing, reach out to us at [email protected] or call +91-8595603096 for expert audit and certification services.

Applicable ISO Standards for Structural Metal Product Manufacturing

The structural metal manufacturing industry is multifaceted, encompassing the production of bridges, frames, pipelines, and other critical components. Below are the key ISO certifications relevant to the industry:

ISO 9001: Quality Management System (QMS)

ISO 9001 sets the benchmark for quality management across industries. It ensures that structural metal manufacturers have systems in place to consistently meet customer and regulatory requirements.

ISO 14001: Environmental Management System (EMS)

Environmental responsibility is crucial. ISO 14001 helps manufacturers manage their environmental impacts by promoting sustainable practices, waste reduction, and energy efficiency.

ISO 45001: Occupational Health and Safety Management

Safety is paramount in metal product manufacturing, where workers often face risks from heavy machinery and materials. ISO 45001 focuses on creating safe working environments and reducing workplace hazards.

ISO 3834: Quality Requirements for Welding

Given the reliance on welding in structural metal product manufacturing, ISO 3834 ensures the quality of welded products through stringent checks on welding processes and personnel.

ISO 1090: Execution of Steel and Aluminum Structures

This standard is specific to steel and aluminum structural components, ensuring they are designed, fabricated, and installed with precision and reliability.

ISO 50001: Energy Management Systems

Energy efficiency is essential for cost management and sustainability. ISO 50001 provides guidelines for optimizing energy use across manufacturing processes.

Other Relevant Standards

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in providing audit and certification services for businesses seeking ISO compliance. With our expertise, we guide manufacturers through the certification process, ensuring seamless adherence to applicable ISO standards.

Our team conducts thorough audits to assess compliance, paving the way for certification issuance that enhances credibility and market competitiveness.

For professional assistance in ISO certification for Structural Metal Product Manufacturing, email [email protected] or call +91-8595603096.

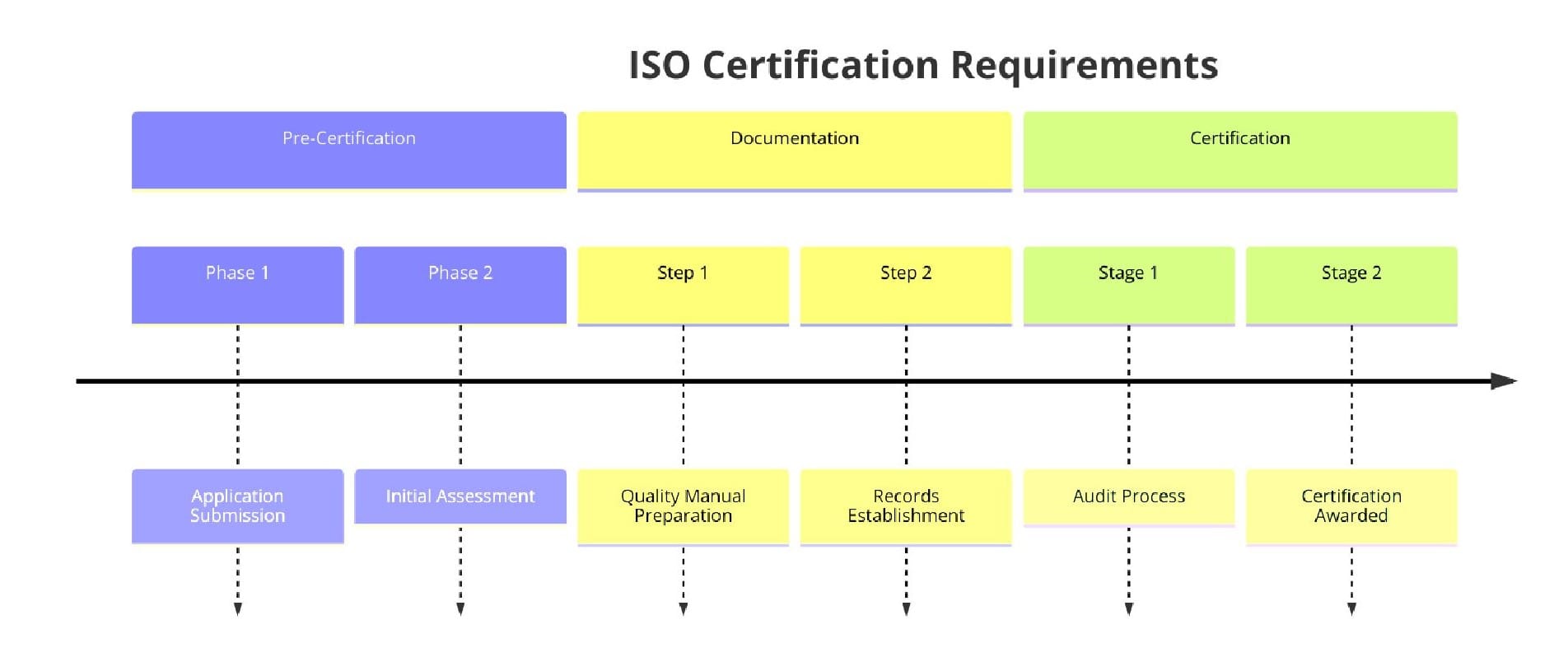

Requirements of ISO Certifications for Structural Metal Product Manufacturing

Adhering to ISO standards requires meeting specific requirements. Below is an overview based on the most common certifications:

ISO 9001 Requirements

- Establishing a quality management system with defined roles and responsibilities.

- Regular audits to monitor compliance and identify areas for improvement.

- Maintaining comprehensive documentation of processes and procedures.

ISO 14001 Requirements

- Identifying and mitigating environmental impacts of manufacturing processes.

- Implementing waste management systems and resource-efficient operations.

- Compliance with local and international environmental laws.

ISO 45001 Requirements

- Conducting risk assessments for workplace safety.

- Providing training and equipment to ensure employee safety.

- Establishing an incident response and mitigation plan.

ISO 3834 Requirements

- Ensuring welding processes meet quality benchmarks.

- Training personnel in welding standards and safety measures.

- Regular inspection and testing of welded components.

ISO 50001 Requirements

- Energy consumption analysis and reporting.

- Implementation of energy-efficient technologies.

- Continuous monitoring and optimization of energy use.

Looking for ISO certification? Contact Pacific Certifications at [email protected] or call +91-8595603096 to get started.

Benefits of ISO Certifications for Structural Metal Product Manufacturing

The benefits of achieving ISO certification extend beyond compliance. Here are some advantages:

Enhanced Quality Control: ISO standards like ISO 9001 provide a robust framework for maintaining consistency in product quality.

Global Market Access: ISO certification is often a prerequisite for entering international markets. It assures customers of adherence to globally recognized standards.

Reduced Environmental Impact: With ISO 14001, manufacturers can adopt eco-friendly practices, enhancing their reputation and contributing to sustainability goals.

Workplace Safety: ISO 45001-certified organizations demonstrate a commitment to employee safety, reducing accidents and ensuring compliance with occupational health laws.

Energy Efficiency: ISO 50001 certification helps businesses reduce energy consumption and operational costs while promoting sustainability.

Customer Trust and Satisfaction: ISO certifications reflect a dedication to quality, safety, and efficiency, building customer trust and satisfaction over time.

Reach out to us at [email protected] or dial +91-8595603096 for ISO certification for Structural Metal Product Manufacturing.

The structural metal manufacturing industry continues to see advancements in automation and safety protocols. In this year, companies are increasingly adopting ISO standards to align with ESG (Environmental, Social and Governance) goals and meet stricter global compliance regulations. Staying updated with these trends ensures businesses remain competitive.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Structural Metal Product Manufacturing business, please contact us at [email protected] or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs