ISO Certifications for Sheet Metal Product Manufacturing Businesses, Requirements and Benefits

Introduction

Sheet metal product manufacturers support critical industries including automotive, aerospace, industrial machinery, consumer appliances, electronics, renewable energy, HVAC, and construction. Operations typically involve cutting, forming, stamping, bending, welding, surface treatment, assembly, and logistics. With precision, durability, corrosion resistance, safety standards, and compliance requirements rising across global supply chains, ISO certifications provide manufacturers with operational discipline, documented quality processes, and competitive trust in domestic and export markets.

With rapid advancements in technology and materials, ISO certifications also keep companies aligned with emerging trends and innovations. These certifications are business necessity in today’s demanding markets.

If you're seeking ISO certification for sheet metal product manufacturing, connect with us at [email protected] or call +91-8595603096. Our team is ready to assist you.

Precision sheet metal manufacturing succeeds not only through machinery and skill, but through structured quality discipline and traceable processes.

Quick Summary

Sheet metal fabricators are increasingly adopting ISO certifications to improve process consistency, welding and cutting quality, workplace safety, energy efficiency, and supplier confidence, while meeting strict OEM and international buyer requirements.

Applicable ISO Standards for Sheet Metal Product Manufacturing

The sheet metal product manufacturing industry benefits from various ISO standards designed to address quality, environmental management, safety, and specialized requirements. Here are the most relevant certifications:

Standard | Description | Relevance |

|---|---|---|

ISO 9001 | Quality Management | Dimensional accuracy, defect control, supplier evaluation, traceability |

ISO 14001 | Environmental Management | Waste, emissions, chemical use, and pollution control |

ISO 45001 | Occupational Health & Safety | Workplace safety for welding, cutting, lifting, and chemical exposure |

ISO 27001 | Information Security | Protection of design files, customer drawings, and production data |

ISO 3834 (Welding Quality) | Welding Process Control | Required for certified welding in automotive, rail, and structural fabrication |

ISO 50001 | Energy Management | Efficiency in cutting, welding, ventilation, and machinery power consumption |

ISO 9001: Quality Management Systems (QMS)

ISO 9001 is a foundational standard for quality management, ensuring that products meet customer expectations and comply with applicable regulations. For sheet metal manufacturers, it guarantees consistency in processes, improving customer satisfaction.

ISO 14001: Environmental Management Systems (EMS)

Environmental sustainability is crucial. ISO 14001 helps companies minimize their environmental impact by promoting efficient use of resources, reducing waste, and adhering to environmental laws.

ISO 45001: Occupational Health and Safety Management Systems

Safety is paramount in sheet metal production. ISO 45001 focuses on creating a safe workplace, reducing accidents, and ensuring employee well-being through proactive risk management.

ISO 50001: Energy Management Systems

Given the energy-intensive nature of sheet metal manufacturing, ISO 50001 aids in optimizing energy use, reducing costs, and improving environmental performance.

ISO 3834: Quality Requirements for Welding

Welding is integral to sheet metal fabrication. ISO 3834 ensures high-quality welding processes, critical for maintaining the structural integrity of products.

ISO 1090: Execution of Steel and Aluminium Structures

This standard specifically applies to the design and manufacturing of steel and aluminium structures, ensuring compliance with safety and performance requirements.

ISO 26000: Social Responsibility

While not certifiable, ISO 26000 provides guidance on corporate social responsibility, ensuring ethical practices and sustainable business operations.

Click here to find out more applicable standards to your industry

Reach out at [email protected] or dial +91-8595603096 for expert guidance on ISO certification tailored to sheet metal manufacturing.

What re the requirements of ISO Certifications for Sheet Metal Product Manufacturing?

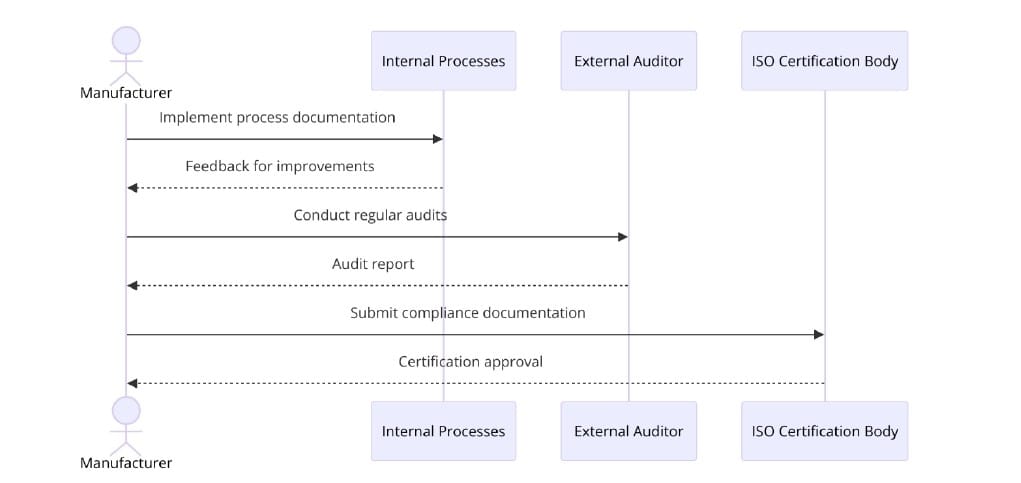

To achieve ISO certification, manufacturers must meet specific requirements outlined by each standard. These requirements ensure the organization’s processes, systems, and outcomes align with the standards' objectives. Below is a breakdown of the core requirements for the most relevant ISO standards in sheet metal product manufacturing:

General requirements:

- Define controlled shop-floor processes for material cutting, bending, welding, assembly, inspection, and packaging with competent accountability roles.

- Conduct end-to-end risk assessments covering welding hazards, electrical systems, fume extraction, chemical handling, and equipment safety.

- Establish documented SOPs for raw material receipt, storage, forming, machining, grinding, weld inspection, finishing, and final quality checks.

- Train welders, CNC operators, machine technicians, inspectors, and safety teams in procedures, PPE use, quality inspection, and hazard response.

- Maintain machine calibration records, welding qualification logs, consumable traceability, and compliance documents for finishing chemicals.

- Conduct internal audits, evaluate defect data and rework trends, review performance metrics, and enhance systems through continual improvement.

Specific requirements:

ISO 9001: Quality Management Systems (QMS)

- Customer Focus: Organizations must prioritize understanding and fulfilling customer requirements, aiming for high satisfaction levels.

- Leadership Commitment: Leadership must actively engage in promoting quality management principles and setting clear organizational goals.

- Process Approach: All processes should be identified, documented, and optimized for consistent outcomes.

- Risk-Based Thinking: Assess and address risks and opportunities to enhance system performance.

- Continuous Improvement: Implement mechanisms for regular reviews and improvements of processes.

- Performance Evaluation: Conduct internal audits and management reviews to ensure ongoing compliance and improvement.

ISO 14001: Environmental Management Systems (EMS)

- Environmental Policy: Develop and maintain a documented policy demonstrating a commitment to environmental protection.

- Legal Compliance: Identify and adhere to all applicable environmental regulations and laws.

- Environmental Objectives: Set measurable objectives to reduce environmental impact and track progress.

- Lifecycle Perspective: Consider environmental impacts at every stage of the product lifecycle.

- Operational Controls: Implement controls to manage significant environmental aspects, such as waste, emissions, and resource use.

- Monitoring and Reporting: Regularly evaluate environmental performance and report on progress toward objectives.

ISO 45001: Occupational Health and Safety Management Systems

- Hazard Identification and Risk Assessment: Identify workplace hazards, assess associated risks, and implement appropriate controls.

- Worker Participation: Involve employees in safety initiatives and decision-making processes.

- Compliance with Legal and Other Requirements: Adhere to health and safety regulations and standards.

- Emergency Preparedness and Response: Develop and test plans for emergencies such as fires, chemical spills, or equipment failures.

- Incident Investigation: Establish procedures for investigating accidents and incidents to prevent recurrence.

- Continuous Monitoring: Measure safety performance and make improvements where needed.

ISO 50001: Energy Management Systems

- Energy Policy: Define and document an energy policy to improve energy efficiency.

- Energy Review: Conduct an assessment to understand energy use and identify opportunities for improvement.

- Baseline and Performance Indicators: Establish an energy baseline and key performance indicators to measure progress.

- Energy Objectives and Targets: Set goals to enhance energy performance, supported by a clear action plan.

- Operational Controls: Implement controls to ensure energy efficiency in daily operations.

- Continuous Improvement: Monitor, measure, and improve energy performance through regular reviews.

ISO 3834: Quality Requirements for Welding

- Competent Personnel: Ensure welders and supervisors have the necessary qualifications and training.

- Inspection and Testing: Implement procedures for pre-production and post-production welding inspections.

- Equipment Maintenance: Maintain welding equipment in optimal condition to ensure process quality.

- Documentation: Keep records of welding activities, including materials, procedures, and inspection results.

- Welding Procedures: Establish and adhere to qualified welding procedure specifications (WPS).

ISO 1090: Execution of Steel and Aluminium Structures

- Structural Design Compliance: Ensure all designs comply with applicable structural safety and performance requirements.

- Factory Production Control (FPC): Establish a system to manage and control production processes consistently.

- Traceability: Maintain traceability of materials and components throughout the manufacturing process.

- Inspection and Testing: Conduct tests such as tensile strength, welding integrity, and dimensional accuracy.

- Documentation: Maintain records to demonstrate compliance with ISO 1090 requirements.

ISO 26000: Guidance on Social Responsibility (Non-Certifiable)

- Ethical Behavior: Uphold high ethical standards in business practices.

- Stakeholder Engagement: Engage with stakeholders, including employees, customers, and communities, to address their concerns.

- Sustainability Commitment: Focus on long-term environmental, social, and economic sustainability.

- Transparency: Maintain openness in reporting on social responsibility efforts and their impact.

Tip: Begin with documenting the full machining and welding workflow from raw sheet intake to finished part dispatch. Assign controls for each stage and emphasize weld quality records, calibration logs, and PPE enforcement, since these areas have direct impact on customer confidence and safety compliance.

For seamless ISO certification services in sheet metal product manufacturing, email [email protected] or call +91-8595603096.

What are the benefits of ISO Certifications for Sheet Metal Product Manufacturing?

ISO certifications provide numerous commercial and operational benefits for metal component manufacturers. Below are the key benefits:

- Improved product tolerance accuracy, weld consistency, and inspection rigor leading to lower rejection rates and higher repeat orders.

- Increased eligibility for OEM vendor approvals, export contracts, and government procurement that recognize ISO-certified suppliers.

- Reduced workplace accidents and safety violations through structured training, hazard controls, ventilation systems, and PPE adherence.

- Better environmental and chemical waste management practices aligned with legal compliance for coatings, lubricants, and cutting fluids.

- Strengthened reputation and trust through documented quality assurance, traceability, and transparent audits.

- Increased efficiency and cost savings through process standardization, planned maintenance, and reduced rework and scrap rates.

The global sheet metal fabrication market is projected to exceed USD 500 billion by 2030, driven by EV manufacturing, renewable energy structures, aerospace components, and industrial automation. Precision tolerance demand has risen due to robotic assembly systems and lightweight metal innovations. India, USA, and EU manufacturers are increasingly integrating laser-cutting automation, IIoT monitoring, and AI-powered inspection, making structured quality systems a necessity.

Over 60 percent of leading fabrication suppliers worldwide hold at least ISO 9001 certification, while adoption of ISO 3834 welding certification has surged in automotive and renewable-energy fabrication segments. Regulatory pressure on worker safety and air quality in welding shops has increased ISO 45001 relevance. Buyers now seek certified suppliers to mitigate supply chain risks and align with global sustainability and safety expectations.

How Pacific Certifications Can Help

Pacific Certifications conducts accredited audits and certification for sheet metal manufacturers to validate their quality, safety, and environmental systems against international standards. Certification helps fabricators demonstrate process discipline, product reliability, worker safety, and ethical operations, which are increasingly mandatory for OEM approvals and export supply chains.

We provide:

• Accredited ISO certification audits for QMS, EMS, OHS, and welding quality standards

• Independent evaluation of machining, welding, finishing, and inspection processes

• Assessment of traceability, calibration, documentation, and safety controls

• Comprehensive audit reports outlining strengths and improvement observations

• Transparent certification decision aligned with accreditation requirements

By aligning with these trends, sheet metal manufacturers can position themselves as leaders in innovation and sustainability.

If you need support with ISO certification for your Sheet Metal Product Manufacturing business, contact us at [email protected] or +91-8595603096.

FAQs: ISO Certifications for Sheet Metal Product Manufacturing

What are the key ISO standards for sheet metal manufacturing?

Key standards include ISO 9001 for quality management, ISO 14001 for environmental management, ISO 45001 for occupational safety, and ISO 3834 for welding quality.

Why is ISO certification important for sheet metal manufacturers?

ISO certification ensures quality, regulatory compliance, customer satisfaction, and operational efficiency, making your business competitive in global markets.

How can Pacific Certifications assist with ISO certification?

Pacific Certifications provides auditing and certification services to help businesses achieve compliance with ISO standards.

What are the benefits of ISO 14001 for sheet metal manufacturing?

ISO 14001 helps reduce environmental impact, enhance resource efficiency, and demonstrate a commitment to sustainability.

How does ISO 45001 improve workplace safety?

ISO 45001 focuses on identifying risks, implementing safety measures, and creating a healthier work environment, reducing accidents and hazards.

Can small sheet metal manufacturers achieve ISO certification?

Yes, ISO standards are scalable and can be implemented by organizations of all sizes, helping small businesses improve processes and expand their market reach.

Author: Pooja

Read More at: Blogs by Pacific Certifications