ISO Certifications for Rail Maintenance Businesses, Requirements and Benefits

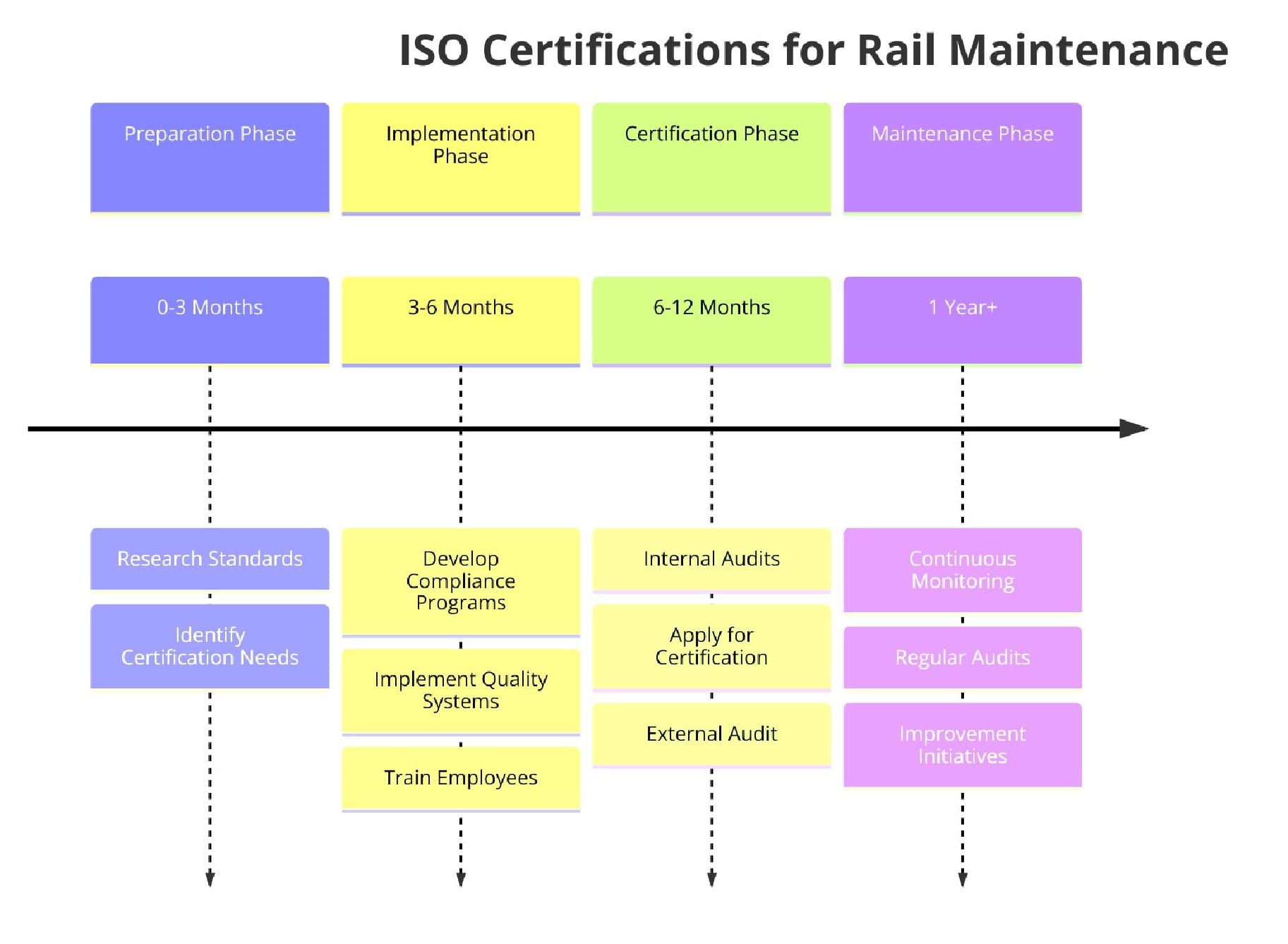

ISO Certifications for Rail Maintenance

Rail maintenance is a crucial aspect of the transportation industry, ensuring that railway systems operate safely and reliably. With increasing passenger and freight demands, maintaining rail infrastructure to the highest standards is essential.

ISO (International Organization for Standardization) has developed various standards that help railway maintenance organizations establish structured processes, safety & improve service quality. These standards define best practices, ensuring compliance with international safety and operational requirements.

For companies involved in rail maintenance, obtaining ISO certification demonstrates a commitment to safety & regulatory compliance. It not only helps meet legal obligations but also boosts customer trust and operational efficiency.

Direct Email Support: Reach out to us at [email protected] for any inquiries regarding ISO certification.

Applicable ISO Standards for Rail Maintenance

Several ISO standards apply to rail maintenance, covering areas such as quality management, safety, environmental impact, and asset management. Below are the key ISO certifications relevant to the rail maintenance industry:

ISO 9001: Quality Management System (QMS)

ISO 9001 is the most widely recognized quality management standard. It ensures that railway maintenance organizations follow structured processes to enhance service quality and customer satisfaction. Certification to ISO 9001 demonstrates a commitment to continual improvement and efficiency.

ISO 14001: Environmental Management System (EMS)

Rail maintenance activities can significantly impact the environment. ISO 14001 helps organizations minimize environmental risks by promoting sustainable practices, reducing waste, and ensuring regulatory compliance.

ISO 45001: Occupational Health & Safety (OHSMS)

Safety is a top priority in rail maintenance. ISO 45001 focuses on improving workplace safety, reducing risks, and preventing accidents. It ensures that maintenance teams operate in a secure and healthy environment.

ISO 55001: Asset Management System (AMS)

Railway maintenance involves managing infrastructure, rolling stock, and other assets efficiently. ISO 55001 provides a framework for optimizing asset performance, reducing downtime, and improving cost-effectiveness.

ISO/TS 22163: Railway Quality Management System (Based on ISO 9001)

This is a specific standard for the railway industry, including maintenance service providers. It builds upon ISO 9001 principles and incorporates railway-specific quality management requirements.

ISO 31000: Risk Management

Risk management is essential in rail maintenance to prevent failures and disruptions. ISO 31000 provides guidelines to identify, assess, and manage risks associated with rail operations.

By obtaining certification in these standards, rail maintenance companies can enhance operational efficiency, safety, and sustainability while ensuring compliance with global best practices.

Click here to find out more applicable standards to your industry

How we can help?

At Pacific Certifications, we specialize in auditing and issuing ISO certifications for rail maintenance companies. As an accredited certification body, we help organizations achieve compliance by conducting audits and verifying adherence to ISO standards.

Our certification services ensure that rail maintenance providers meet industry regulations and improve operational performance. We do not offer consultancy, training, or implementation services, but we are committed to delivering a transparent and efficient certification process.

If your organization is looking to obtain ISO certification for rail maintenance, we provide expert audit services to help you meet industry standards.

Certification Process Guidance: Email [email protected] to get step-by-step details on obtaining ISO certification.

Requirements of ISO Certifications for Rail Maintenance

Each ISO standard applicable to rail maintenance has specific requirements. Below is a breakdown of the key requirements for each standard:

ISO 9001: Quality Management System (QMS) requirements:

- Establish a documented quality management system (QMS).

- Define quality policies and objectives.

- Conduct regular internal audits and performance evaluations.

- Ensure customer satisfaction through continuous improvement.

- Maintain records of maintenance activities and corrective actions.

ISO 14001: Environmental Management System (EMS) requirements:

- Identify and manage environmental risks in rail maintenance.

- Implement sustainable practices to reduce emissions and waste.

- Comply with environmental regulations and legal requirements.

- Monitor environmental performance and set improvement targets.

- Conduct regular environmental impact assessments.

ISO 45001: Occupational Health & Safety Management System (OHSMS) requirements:

- Establish a workplace safety policy and risk management framework.

- Conduct hazard identification and risk assessments.

- Provide safety training for employees and maintenance teams.

- Implement emergency preparedness and response plans.

- Monitor workplace incidents and take preventive measures.

ISO 55001: Asset Management System (AMS) requirements:

- Develop an asset management policy and strategy.

- Maintain and optimize rail infrastructure and rolling stock.

- Implement a lifecycle approach for assets to reduce costs and downtime.

- Conduct risk assessments related to asset failures.

- Ensure regular inspections and maintenance of assets.

ISO/TS 22163: Railway Quality Management System requirements:

- Comply with railway-specific quality management requirements.

- Implement a structured approach to process control and documentation.

- Ensure supplier and subcontractor compliance with railway standards.

- Conduct risk assessments related to railway operations.

- Monitor performance through audits and corrective actions.

ISO 31000: Risk Management requirements:

- Identify potential risks in rail maintenance operations.

- Assess and prioritize risks based on their impact and likelihood.

- Implement risk mitigation and control measures.

- Monitor and review risk management strategies regularly.

- Establish a culture of risk awareness and proactive decision-making.

By meeting these requirements, rail maintenance companies can enhance safety, efficiency, and compliance while achieving ISO certification.

Need an audit? Contact us at [email protected] to arrange an assessment.

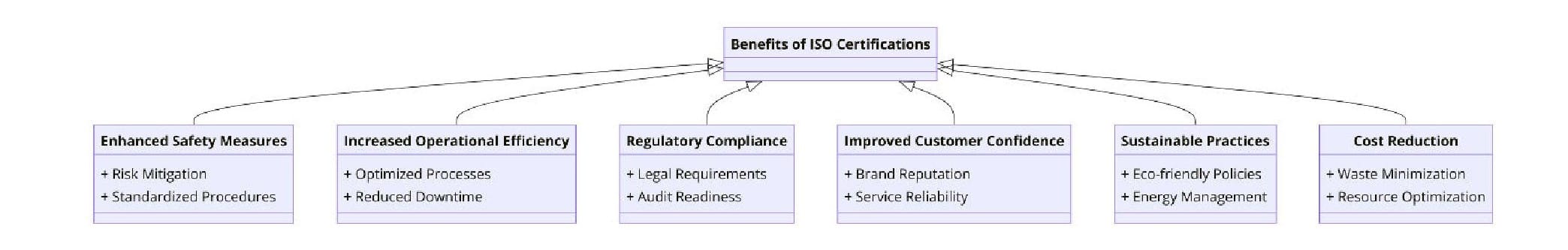

Benefits of ISO Certifications for Rail Maintenance

Safety & Reliability: ISO standards help rail maintenance companies implement strict safety protocols, reducing the risk of accidents and improving operational reliability.

Compliance: ISO certification ensures compliance with national and international railway regulations, reducing legal risks and enhancing reputation.

Efficiency & Cost Savings: By optimizing processes and asset management, ISO standards contribute to reduced operational costs, lower maintenance downtime, and better resource utilization.

Sustainability: ISO 14001 promotes eco-friendly maintenance practices, reducing carbon footprints and ensuring responsible waste management.

Competitive Advantage: ISO certification enhances credibility, making it easier for rail maintenance providers to win contracts and establish trust with clients.

Risk Management & Business Continuity: By adopting ISO 31000 risk management principles, companies can proactively address risks, ensuring long-term sustainability and resilience.

Customer & Stakeholder Confidence: Certified rail maintenance companies demonstrate reliability and professionalism, strengthening relationships with customers, regulators, and stakeholders.

The rail maintenance industry is undergoing significant advancements this year, driven by digital transformation and sustainability goals. According to industry reports, global railway maintenance spending is expected to grow by 5% annually, with increasing investments in predictive maintenance technologies and eco-friendly infrastructure.

Governments and private operators are prioritizing AI-driven predictive maintenance, automation, and green energy solutions to enhance efficiency and reduce environmental impact. Compliance with ISO standards is becoming a key differentiator for companies looking to secure contracts and expand globally.

Conclusion

If your organization is involved in rail maintenance and looking to achieve ISO certification, Pacific Certifications is here to help. Our expert audit services ensure that you meet industry standards, enhance efficiency & stay ahead of regulatory requirements.

Get certified today! Contact us for a seamless and professional certification process.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Rail Maintenance business, please contact us at [email protected]or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs