ISO Certifications for Plastic Flooring and Polymer Product Manufacturing Businesses

In the fast-evolving world of manufacturing, achieving excellence is a necessity. The global plastic flooring and polymer product industries are no exception, with strict compliance and quality benchmarks set by ISO standards. If you aim to ensure product reliability and meet environmental and safety criteria, obtaining ISO certifications is the key to success.

ISO certifications represent international best practices and frameworks, helping industries establish standardized procedures and maintain consistent quality. For plastic flooring and polymer product manufacturing, these certifications are essential in ensuring the durability, sustainability, and safety of products.

ISO standards address critical aspects such as product quality, environmental impact, safety, and efficiency. By implementing standards, manufacturers gain trust and credibility in an increasingly eco-conscious market.

If you're ready to achieve ISO certification for your plastic flooring or polymer manufacturing business, email us at [email protected] or call us at +91-8595603096 for expert guidance.

Applicable ISO Standards for Plastic Flooring and Polymer Product Manufacturing

The plastic flooring and polymer industries must comply with various ISO certifications tailored to their specific needs:

ISO 9001: Quality Management Systems (QMS)

ISO 9001 focuses on streamlining processes, ensuring customer satisfaction, and delivering consistent product quality. It is pivotal for maintaining high manufacturing standards and managing risks effectively.

ISO 14001: Environmental Management Systems (EMS)

Environmental concerns are at the forefront of the polymer and plastics industry. ISO 14001 helps manufacturers minimize their environmental footprint, manage waste, and comply with regulatory requirements.

ISO 45001: Occupational Health and Safety Management Systems

Worker safety is a top priority in manufacturing. ISO 45001 addresses workplace hazards, promoting safe working conditions and ensuring employee well-being.

ISO 50001: Energy Management Systems

Efficient energy use is crucial for cost-saving and sustainability. ISO 50001 enables manufacturers to optimize energy consumption, reducing operational expenses and environmental impact.

ISO 21702: Measurement of Antiviral Activity on Plastics and Other Non-Porous Surfaces

This standard is essential for manufacturers producing antimicrobial polymer products. It evaluates the antiviral properties of plastics, especially significant post-COVID-19.

ISO 178: Determination of Flexural Properties of Plastics

ISO 178 is integral to testing the mechanical strength and durability of plastic products, ensuring they meet performance expectations.

ISO 18395: Plastics—Environmental Aspects

This certification focuses on sustainable manufacturing practices, emphasizing the lifecycle impact of polymer products.

ISO 15378: Primary Packaging Materials for Medicinal Products

For polymer products used in medical packaging, ISO 15378 ensures compliance with Good Manufacturing Practices (GMP), critical for patient safety.

Click here to find out more applicable standards to your industry

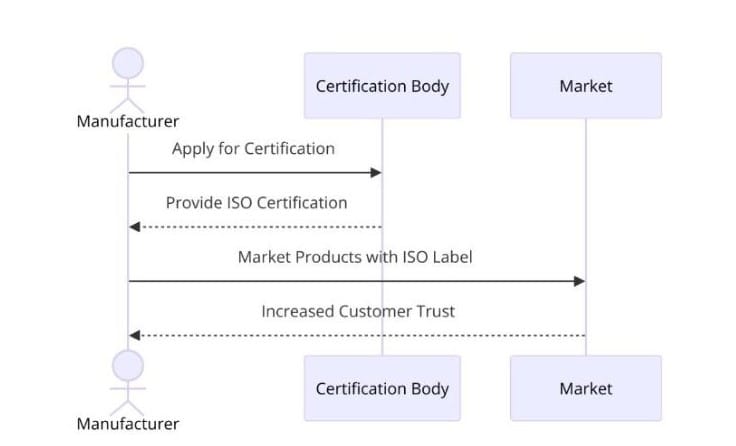

At Pacific Certifications, we specialize in conducting audits and issuing ISO certifications tailored to the plastic flooring and polymer manufacturing sectors. Our process ensures that your organization meets all necessary requirements while streamlining your path to certification. With years of expertise, our team offers:

- Unbiased audits aligned with ISO standards.

- Comprehensive certification issuance services.

- Assistance in ensuring ongoing compliance with ISO standards.

By partnering with Pacific Certifications, you gain a reliable certification body committed to your success.

For reliable ISO certification services in plastic flooring and polymer manufacturing, get in touch via [email protected] or call +91-8595603096 today.

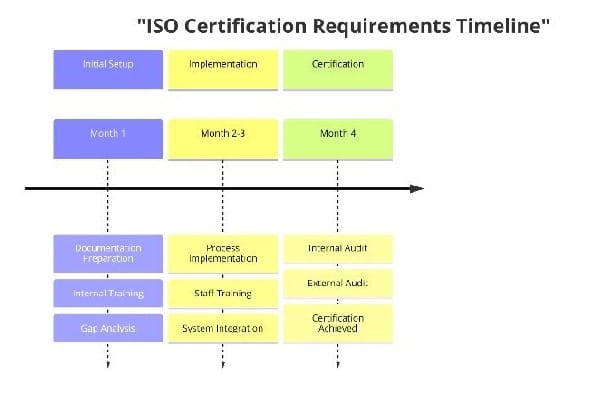

Requirements of ISO Certifications for Plastic Flooring and Polymer Product Manufacturing

ISO 9001 Requirements

- Establish a robust Quality Management System.

- Continuous monitoring and improvement of production processes.

- Documented processes for quality checks and customer feedback.

ISO 14001 Requirements

- Conduct an environmental impact assessment.

- Implement measures to minimize pollution and waste.

- Maintain documentation of environmental management practices.

ISO 45001 Requirements

- Identify and mitigate workplace hazards.

- Develop a safety policy and provide regular training.

- Ensure compliance with occupational health and safety regulations.

ISO 50001 Requirements

- Assess current energy usage and identify areas for improvement.

- Set measurable energy performance goals.

- Maintain records of energy management initiatives.

ISO 21702 Requirements

- Conduct rigorous testing for antiviral properties.

- Adhere to protocols for non-porous surface evaluation.

ISO 178 Requirements

- Perform flexural testing to measure material resistance.

- Document results to verify product strength and compliance.

Compliance with these standards requires meticulous preparation and adherence to detailed specifications, ensuring your business aligns with global expectations.

Achieve global standards with Pacific Certifications. Email us at [email protected] or call +91-8595603096 to discuss your ISO certification needs.

Benefits of ISO Certifications for Plastic Flooring and Polymer Product Manufacturing

Product Quality: ISO certifications drive consistency and precision in production, resulting in superior-quality products that satisfy customer expectations.

Market Access: Many clients and governments mandate ISO-certified suppliers. Certification opens doors to new markets and partnerships.

Environmental Responsibility: With ISO 14001 and similar standards, manufacturers can demonstrate their commitment to sustainability, a key factor in attracting eco-conscious customers.

Efficiency: ISO standards streamline manufacturing processes, reducing waste and optimizing resource utilization for cost savings.

Reputation and Credibility: ISO certification is a globally recognized mark of excellence, boosting your brand’s reputation and customer trust.

Workplace Safety: Compliance with ISO 45001 ensures a safer working environment, reducing risks and boosting employee morale.

Legal and Regulatory Compliance: Adhering to ISO standards helps businesses stay compliant with international regulations, avoiding fines and legal complications.

In this year, the polymer industry is poised for growth, driven by advancements in sustainable materials and stricter environmental regulations. A recent report highlights an increasing demand for recycled plastic flooring in residential and commercial spaces. Manufacturers prioritizing eco-friendly practices, such as achieving ISO 14001 certification, are leading the market.

Trends also show a shift toward antimicrobial polymer products, with ISO 21702 gaining significance. As health-conscious consumers seek hygienic solutions, this standard plays a pivotal role in ensuring product safety and efficacy.

Ready to take your plastic flooring and polymer manufacturing business to the next level? Partner with Pacific Certifications to achieve ISO compliance and set your brand apart.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Plastic Flooring and Polymer Product Manufacturing business, please contact us at [email protected] or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs