ISO Certifications for Paper Product Manufacturing Businesses, Requirements and Benefits

ISO Certifications for Paper Product Manufacturing Businesses

ISO certifications play a key role in ensuring that paper product manufacturing businesses maintain high-quality standards and meet environmental and safety requirements.

ISO 9001:2015 focuses on quality management, helping companies to reduce defects and optimize production. Also increases customer satisfaction through continuous improvement. To support sustainable operations, ISO 14001:2015 provides guidelines for managing environmental impacts by minimizing waste and resource consumption.

ISO 50001 helps businesses to increase energy efficiency, reducing operational costs. Meanwhile, ISO 45001 ensures employee safety by addressing workplace hazards and minimizing risks. In cases where paper products are used for food packaging, ISO 22000 guarantees food safety by preventing contamination and meeting regulatory standards.

These certifications align operations and also build trust among clients and partners, open doors to international markets, allowing paper manufacturers to stay ahead through sustainable and safe production practices.

If you're seeking ISO certification for your paper product manufacturing business, contact us at [email protected] to get started!

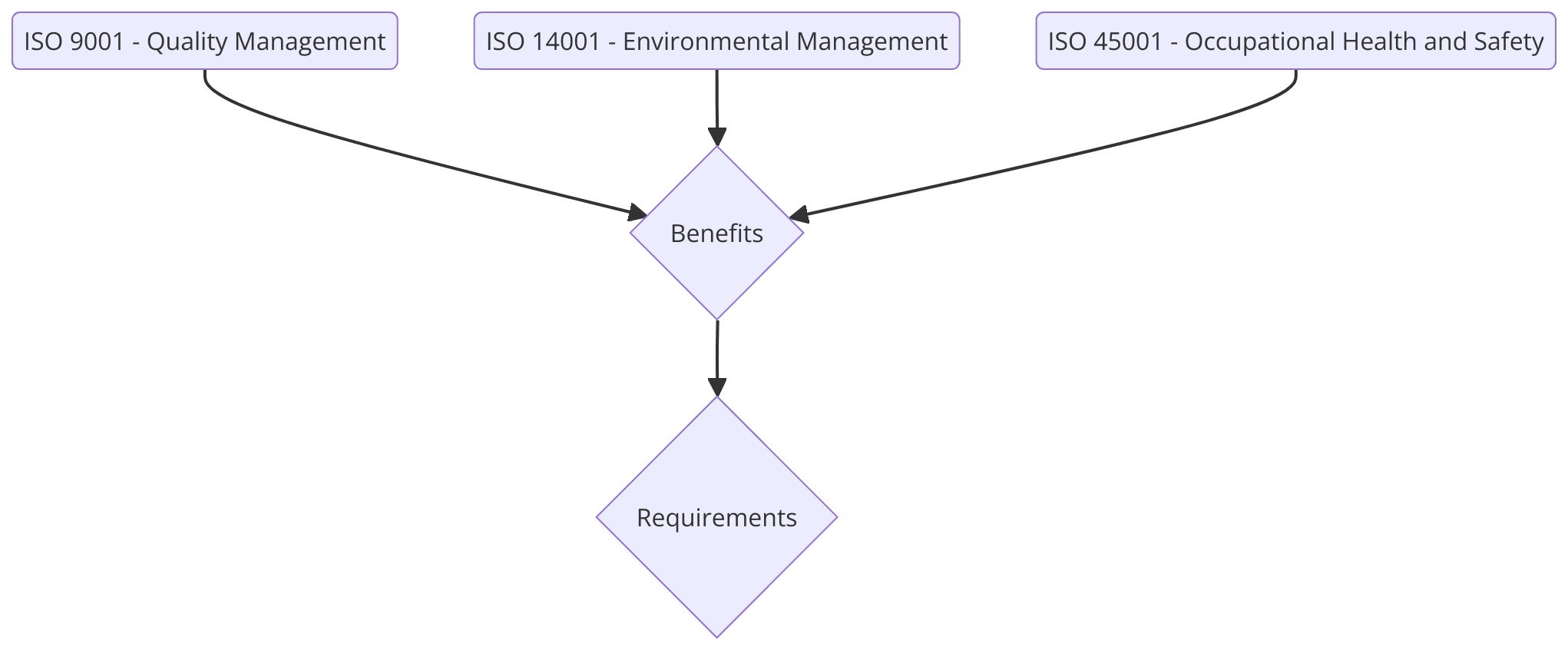

Applicable ISO Standards for Paper Product Manufacturing

Several ISO standards apply to the paper product manufacturing industry, each focusing on different aspects of the manufacturing process. Below are the key ISO standards for this industry:

ISO 9001:2015 – Quality Management System

ISO 9001:2015 sets the foundation for a strong quality management system (QMS). For paper product manufacturers, implementing ISO 9001 ensures consistency in product quality, minimizes defects and enhances customer satisfaction.

ISO 14001:2015 – Environmental Management System

ISO 14001 helps organizations manage their environmental responsibilities by implementing an environmental management system (EMS).

ISO 45001:2018 – Occupational Health and Safety Management

ISO 45001 helps manufacturers establish a safe working environment by identifying hazards, minimizing risks, and promoting a culture of health and safety.

ISO 50001:2018 – Energy Management System

ISO 50001 focuses on improving energy use and consumption through an energy management system (EnMS). By optimizing energy usage, companies can reduce costs and minimize their carbon footprint.

ISO 22000:2018 – Food Safety Management

This standard ensures that the packaging does not compromise food safety. ISO 22000 focuses on preventing contamination and ensuring safe food packaging materials.

ISO 27001:2022 – Information Security Management System

ISO 27001 can apply to paper product manufacturers dealing with sensitive data, including customer information and trade secrets. Implementing an information security management system (ISMS) helps protect data from breaches and cyber threats.

Click here to find out more applicable standards to your industry

Ensure your paper product manufacturing meets global standards. For ISO certification assistance, reach out to us at [email protected] or +91-8595603096.

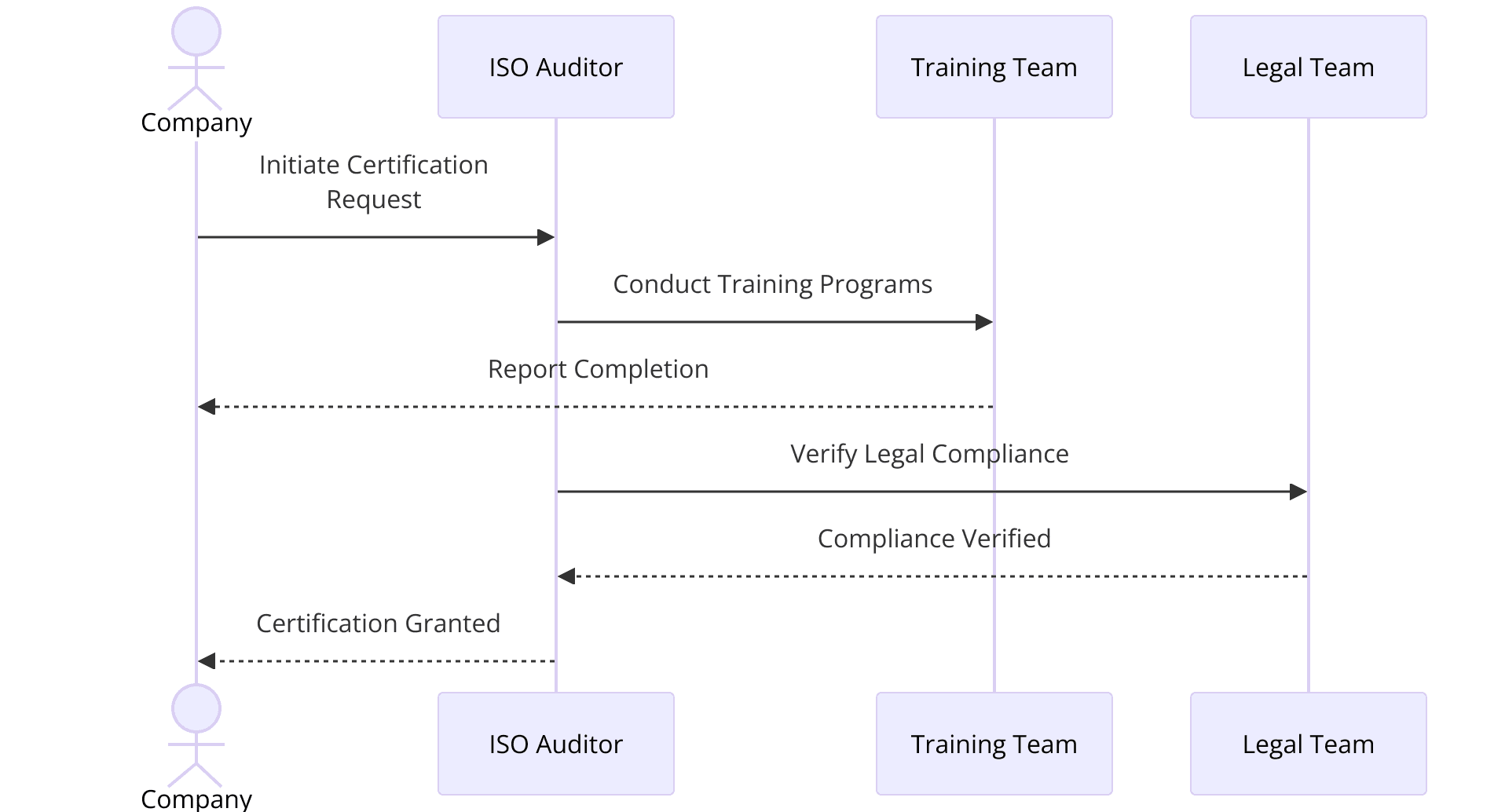

How We Can Help?

At Pacific Certifications, we specialize in helping paper product manufacturing firms to achieve ISO certifications through a streamlined audit and certification process. Our role as a certification body is to evaluate your compliance with ISO standards and provide certification once all requirements are met.

We focus solely on auditing and certification to maintain impartiality and ensure that your company’s processes meet international standards.

Our Services Include:

- Pre-Audit Evaluation: We conduct a thorough audit of your existing systems to determine whether they comply with the ISO standard you're aiming to achieve.

- Certification Audits: Our experienced auditors will review your processes and ensure compliance with the necessary ISO standards.

- Surveillance Audits: To maintain your ISO certification, we offer annual surveillance audits to ensure continued compliance.

- Re-certification Audits: After the certification cycle, we help you renew your certification by conducting a re-certification audit.

Ready to achieve ISO certification for your paper product manufacturing? Email us at [email protected]!

Requirements of ISO Certifications for Paper Product Manufacturing

Each ISO standard has specific requirements that paper product manufacturers must meet. Here’s a breakdown of the key requirements for some of the most relevant standards:

ISO 9001:2015 – Quality Management System Requirements

- Process Control: Companies must establish clear, consistent processes for product development, manufacturing, and quality control.

- Customer Focus: Manufacturers must demonstrate a commitment to understanding customer needs and delivering quality products that meet or exceed expectations.

- Continuous Improvement: Organizations must continuously monitor and improve their quality management system to enhance performance.

ISO 14001:2015 – Environmental Management System Requirements

- Environmental Policy: Companies must have a documented policy that demonstrates their commitment to minimizing environmental impacts.

- Compliance Obligations: Manufacturers must identify and comply with environmental regulations relevant to their operations.

- Resource Management: Efficient use of resources, including energy and water, is a critical aspect of ISO 14001 compliance.

ISO 45001:2018 – Occupational Health and Safety Management Requirements

- Risk Assessment: Manufacturers must conduct regular risk assessments to identify potential hazards in the workplace.

- Incident Reporting: A system must be in place for reporting and investigating workplace incidents and accidents.

- Safety Training: Regular safety training for employees is essential to maintaining a safe working environment.

ISO 50001:2018 – Energy Management System Requirements

- Energy Performance Indicators (EnPIs): Companies must track and monitor key indicators of energy consumption.

- Energy Action Plans: Manufacturers should develop and implement action plans to improve energy efficiency and reduce consumption.

ISO 22000:2018 – Food Safety Management System Requirements

- Hazard Analysis and Critical Control Points (HACCP): Companies must implement HACCP principles to manage food safety risks.

- Compliance with Food Safety Regulations: Manufacturers must comply with local and international food safety standards.

Get certified for excellence in paper product manufacturing. Contact us at [email protected] or +91-8595603096 for ISO certification services.

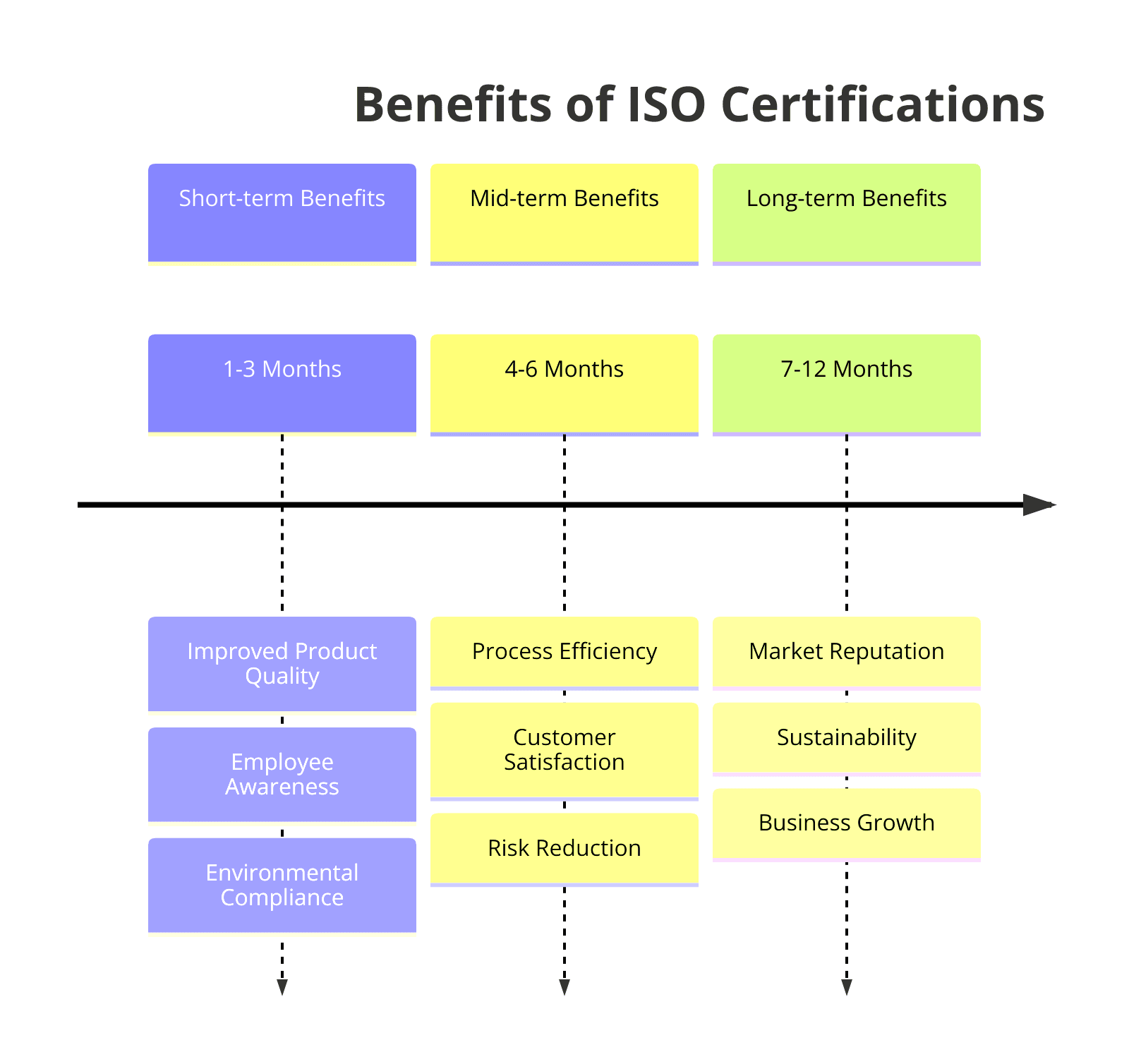

Benefits of ISO Certifications for Paper Product Manufacturing

Achieving ISO certification offers numerous benefits to paper product manufacturers. Here’s how ISO certification can help your business:

Product Quality

ISO certifications such as ISO 9001 emphasize consistency and quality. With well-defined processes, manufacturers can reduce defects and deliver high-quality paper products consistently.

Environmental Sustainability

ISO 14001 enables paper product manufacturers to reduce their environmental footprint by adopting eco-friendly practices.

Safety and Compliance

ISO 45001 certification ensures a safer working environment by identifying and mitigating risks.

Cost Savings

Implementing ISO 50001 for energy management leads to significant cost savings by improving energy efficiency.

Competitiveness

ISO certifications are globally recognized and respected. By achieving certification, paper product manufacturers can stand out in the marketplace.

Regulatory Compliance

ISO certifications help companies stay compliant with both local and international regulations.

Looking for ISO certification for your paper product manufacturing company? Contact us today at [email protected] or call +91-8595603096.

Market Trends

In this year, the global paper product manufacturing industry is increasingly focusing on sustainability, with a shift towards recycled materials and eco-friendly packaging.

As more countries introduce regulations on single-use plastics and other environmentally harmful materials, paper manufacturers are expected to play a key role in providing sustainable alternatives.

According to recent market research, the demand for paper-based packaging solutions is projected to grow by over 4% annually, driven by e-commerce and environmental initiatives.

Additionally, energy efficiency and carbon footprint reduction remain key trends in 2024, as companies strive to meet stricter regulations and reduce operational costs. ISO certifications, particularly ISO 14001 and ISO 50001, will continue to be highly sought after as manufacturers seek to align with these trends and remain competitive.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Paper Product manufacturing business, please contact us at [email protected] or +91-8595603096.

Read More at: Blogs by Pacific Certifications

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs