ISO Certifications for Pallets and Wood Products Manufacturing Businesses, Requirements and Benefits

Quick Summary

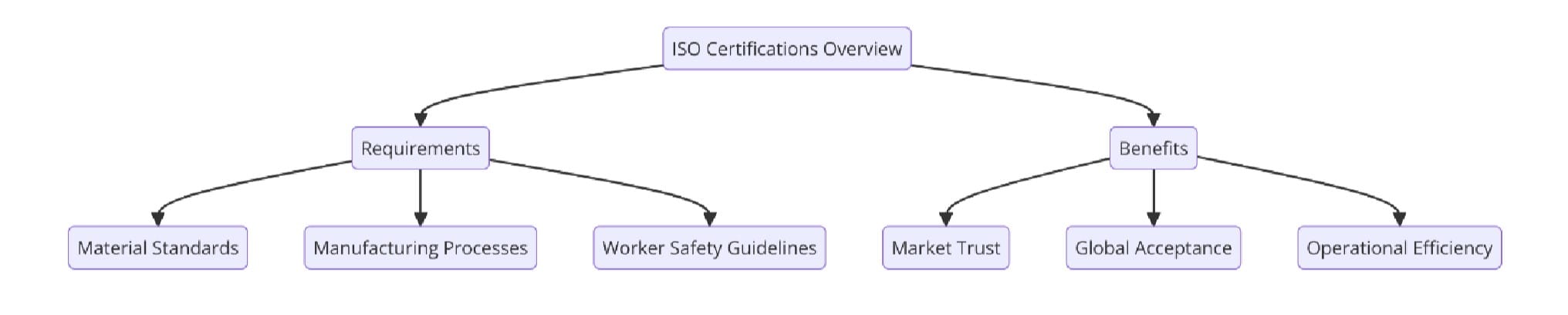

Manufacturers of pallets and wood products face growing expectations for quality, sustainability, and regulatory alignment. ISO certifications offer essential frameworks: ISO 9001 for consistent quality management; ISO 14001 for environmental stewardship; ISO 45001 for workplace health and safety; ISO 38200 for traceable, responsible sourcing; ISO 31000 for risk management; ISO 26000 for social responsibility; and ISO 50001 for energy efficiency. Certification requires documented processes, internal audits, and third-party evaluation. The benefits are substantial: enhanced customer confidence, regulatory compliance, streamlined operations, competitive edge in contracts, safer work environments, and stronger sustainability credentials.

ISO Certifications for Pallets and Wood Products Manufacturing

In today’s global market, compliance with internationally recognized standards is critical for businesses in the pallets and wood products manufacturing industry. ISO certifications serve as a benchmark for quality and sustainability, ensuring that manufacturers can meet customer expectations while adhering to regulatory requirements.

The pallet and wood products industry plays an essential role in logistics, construction, and numerous manufacturing processes. However, as global trade expands, the demand for standardized production and safety practices grows.

ISO standards provide a universal framework to address these challenges. These standards ensure that manufacturers adopt efficient processes, reduce environmental impact, and meet legal obligations. For businesses dealing with wood products, obtaining ISO certifications can help validate their commitment to quality, sustainability, and responsible sourcing.

Contact us at [email protected] or call +91-8595603096 for assistance with ISO certifications for pallets and wood products manufacturing.

Applicable ISO Standards for Pallets and Wood Products Manufacturing

Several ISO standards are applicable to pallets and wood products manufacturing, covering quality management, environmental sustainability, occupational health, and more:

ISO 9001: Quality Management Systems (QMS)

ISO 9001 ensures that manufacturers adhere to quality management principles. For pallet and wood product manufacturers, it guarantees consistency in production, customer satisfaction, and efficient processes.

ISO 14001: Environmental Management Systems (EMS)

With environmental concerns on the rise, ISO 14001 emphasizes sustainable practices. Wood product manufacturers can use this standard to manage resources responsibly and minimize their environmental footprint.

ISO 45001: Occupational Health and Safety

Worker safety is a priority in manufacturing industries. ISO 45001 provides a framework to identify risks, implement safety protocols, and improve overall workplace safety in pallet and wood product facilities.

ISO 38200: Chain of Custody of Wood and Wood-Based Products

This standard is pivotal for companies involved in the production of pallets and wood products. It focuses on traceability, ensuring that raw materials come from legal and sustainable sources.

ISO 31000: Risk Management

Managing risks is crucial in maintaining operational stability. ISO 31000 helps organizations identify and mitigate risks, including supply chain disruptions and safety concerns.

ISO 26000: Social Responsibility

For manufacturers aiming to enhance their corporate responsibility, ISO 26000 provides guidance on ethical business practices and community engagement.

ISO 50001: Energy Management

Energy efficiency is a major focus in the industry. ISO 50001 helps manufacturers reduce energy consumption, lower costs, and contribute to global sustainability goals.

Click here to find out more applicable standards to your industry

How we can help?

As an accredited certification body, Pacific Certifications specializes in auditing and certifying businesses against various ISO standards. With expertise in the pallets and wood products manufacturing sector, Pacific Certifications ensures that your organization meets the required standards, enhancing your reputation and market competitiveness.

Our Role

- Conducting impartial audits to assess compliance with ISO standards.

- Issuing globally recognized ISO certifications to boost customer trust.

- Offering support throughout the certification process to streamline your journey.

By partnering with Pacific Certifications, you gain a trusted ally committed to upholding the integrity and value of your ISO certification.

Ensure compliance and gain customer trust with ISO certification. Contact Pacific Certifications today at [email protected] or call +91-8595603096 for expert help in achieving certification.

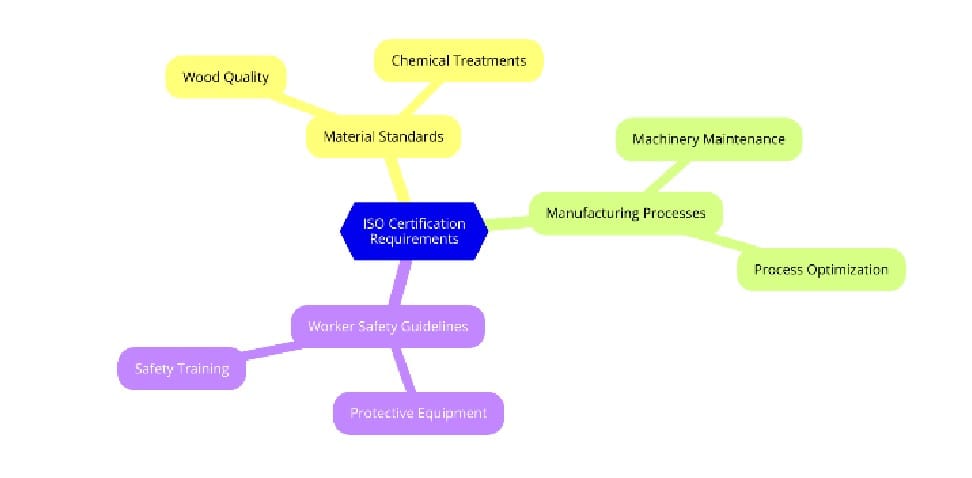

Requirements of ISO Certifications for Pallets and Wood Products Manufacturing

Understanding the specific requirements of each ISO standard is essential for compliance and successful certification. Below is a detailed breakdown of the requirements for each standard applicable to pallets and wood products manufacturing.

ISO 9001: Quality Management Systems (QMS)

- Quality Policy and Objectives: Develop a documented quality policy aligned with the organization’s goals.

- Process-Based Approach: Identify and document all processes critical to product quality.

- Risk Management: Assess risks and opportunities affecting product quality.

- Performance Monitoring: Regularly measure, analyze, and improve key performance indicators (KPIs).

- Customer Focus: Maintain processes that prioritize customer needs and feedback.

- Internal Audits: Conduct regular audits to ensure compliance and continual improvement.

ISO 14001: Environmental Management Systems (EMS)

- Environmental Policy: Establish a policy that outlines your commitment to environmental protection.

- Environmental Impact Assessment: Identify and assess environmental aspects of your operations, including emissions, waste, and resource use.

- Compliance Obligations: Ensure adherence to environmental laws and regulations.

- Operational Controls: Implement procedures to minimize environmental impact during manufacturing.

- Monitoring and Measurement: Continuously monitor energy use, waste generation, and environmental performance.

- Emergency Preparedness: Develop a plan to handle environmental incidents, such as chemical spills.

ISO 45001: Occupational Health and Safety Management Systems

- Hazard Identification: Identify workplace hazards and assess associated risks.

- Safety Policy: Develop and communicate a health and safety policy to all employees.

- Legal Compliance: Meet all legal and regulatory safety requirements.

- Employee Participation: Involve employees in safety planning and decision-making.

- Incident Reporting: Establish a system for reporting and investigating workplace incidents.

- Continual Improvement: Monitor safety performance and implement corrective actions as needed.

ISO 38200: Chain of Custody of Wood and Wood-Based Products

- Chain of Custody System: Establish a traceable process for sourcing, processing, and distributing wood products.

- Documented Procedures: Maintain records of supplier certifications and material flow.

- Legal Compliance: Verify that sourced wood meets legal and sustainability standards.

- Material Identification: Clearly identify and segregate certified and non-certified materials.

Each of these ISO standards provides a structured framework to enhance quality and efficiency in pallets and wood products manufacturing. For expert auditing and certification services, contact Pacific Certifications at [email protected]!

Benefits of ISO Certifications for Pallets and Wood Products Manufacturing

Investing in ISO certifications offers numerous advantages for manufacturers in this industry. From operational efficiency to market competitiveness, these benefits are transformative:

Customer Confidence: ISO certifications demonstrate your commitment to quality, safety, and sustainability, building trust among clients and stakeholders.

Regulatory Compliance: Compliance with international standards ensures that your business meets legal and industry-specific requirements, reducing the risk of penalties.

Efficiency: Adopting ISO standards streamlines processes, minimizes waste, and improves productivity, resulting in cost savings.

Market Competitiveness: In a competitive market, ISO certifications serve as a differentiator, helping your business stand out in tenders and contracts.

Sustainability Goals: ISO 14001 and ISO 38200 certifications reflect your commitment to sustainable practices, attracting eco-conscious customers and partners.

Workplace Safety: With ISO 45001, you can foster a safer working environment, boosting employee morale and reducing downtime from accidents.

Market Trends

The global pallets and wood products industry is experiencing rapid growth, driven by e-commerce, logistics, and a rising emphasis on sustainability. According to recent research, the demand for certified sustainable wood products is expected to grow by 15% in 2026.

Furthermore, businesses are adopting digital tools to track the origin of materials, ensuring compliance with standards like ISO 38200. This shift highlights the importance of ISO certifications in meeting modern customer expectations.

Contact us

At Pacific Certifications, we are here to guide you through the certification journey. Our expertise ensures that you achieve ISO compliance efficiently and effectively.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Pallets and Wood Products Manufacturing business, please contact us at [email protected] or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs