ISO Certifications for Motor Vehicle Parts and Accessories Manufacturing Businesses

ISO Standards for Motor Vehicle Parts and Accessories Manufacturing

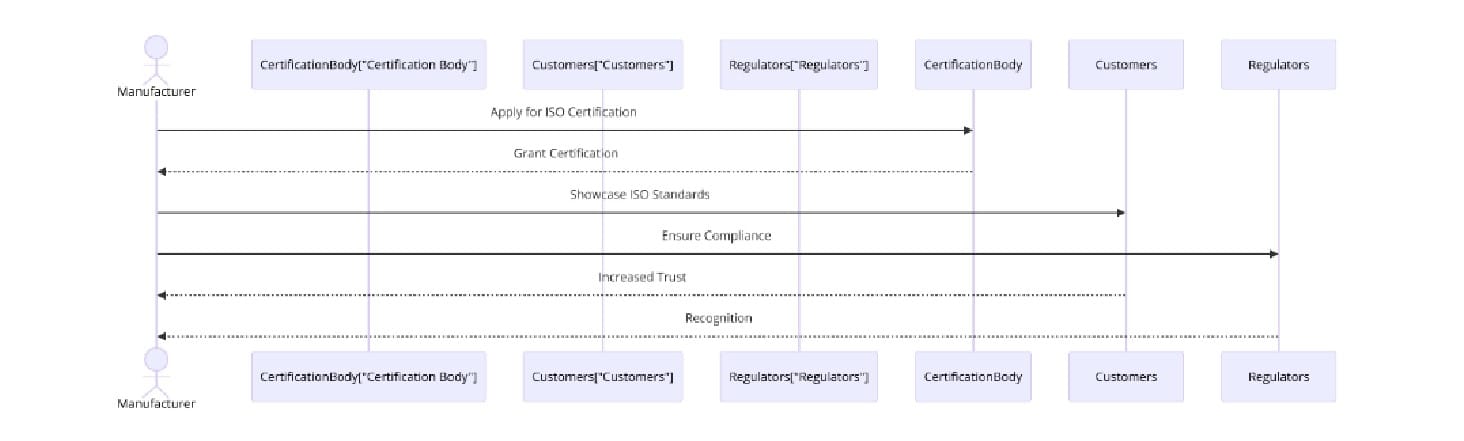

Manufacturing motor vehicle parts and accessories requires uncompromising standards to ensure quality, safety, and compliance with global regulations. In this competitive industry, implementing internationally recognized standards is critical. Whether you are a supplier, manufacturer, or distributor, ISO certifications not only demonstrate your commitment to excellence but also open doors to global markets.

ISO standards provide a globally recognized framework for maintaining quality, safety, and efficiency. For the motor vehicle parts and accessories manufacturing sector, these standards are essential to meet regulatory demands, reduce risks, and enhance product reliability.

From improving operational processes to ensuring environmental sustainability, ISO certifications are integral for manufacturers aiming to stay ahead in a highly regulated and competitive market.

Looking to get ISO certification for Motor Vehicle Parts and Accessories Manufacturing? Contact us at [email protected] or call us at +91-8595603096 to begin your journey towards excellence.

Applicable ISO Standards for Motor Vehicle Parts and Accessories Manufacturing

Several ISO standards are tailored for the motor vehicle manufacturing industry. Below are the key certifications applicable:

ISO 9001: Quality Management Systems

ISO 9001 focuses on quality management principles to enhance customer satisfaction, streamline processes, and improve organizational efficiency. For motor vehicle parts manufacturers, this standard ensures that the quality of components consistently meets customer expectations.

IATF 16949: Automotive Quality Management

Developed specifically for the automotive industry, IATF 16949 builds upon ISO 9001 with additional requirements tailored to vehicle component manufacturers. This certification is critical for managing production risks, preventing defects, and maintaining product reliability.

ISO 14001: Environmental Management Systems

ISO 14001 emphasizes sustainable practices by helping organizations manage their environmental impact. Compliance with this standard demonstrates a commitment to reducing emissions, waste, and resource consumption.

ISO 45001: Occupational Health and Safety Management

ISO 45001 ensures a safe working environment for employees by identifying and mitigating workplace hazards. For manufacturers, this certification supports a culture of health and safety, reducing operational disruptions caused by workplace incidents.

ISO 31000: Risk Management

Risk management is paramount in the automotive sector. ISO 31000 provides a systematic approach to identifying, evaluating, and addressing risks associated with production, supply chains, and operational processes.

ISO 26262: Functional Safety for Automotive Systems

This standard focuses on the functional safety of electrical and electronic systems in vehicles. It is critical for manufacturers producing advanced driver-assistance systems (ADAS), sensors, and other high-tech automotive components.

ISO 50001: Energy Management Systems

Energy efficiency is vital for reducing costs and improving sustainability. ISO 50001 helps organizations optimize energy usage across operations, reducing carbon footprints and operational expenses.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in auditing and certifying manufacturers for ISO standards. Our team provides end-to-end support in evaluating your compliance with applicable ISO requirements. With a deep understanding of the motor vehicle parts industry, we deliver reliable and seamless certification processes.

By partnering with Pacific Certifications, your business gains the credibility and recognition associated with ISO-certified operations. We focus exclusively on auditing and issuing certifications, enabling you to meet industry standards effortlessly.

Want to enhance your manufacturing standards with ISO certification? Get in touch at [email protected] or call +91-8595603096 today!

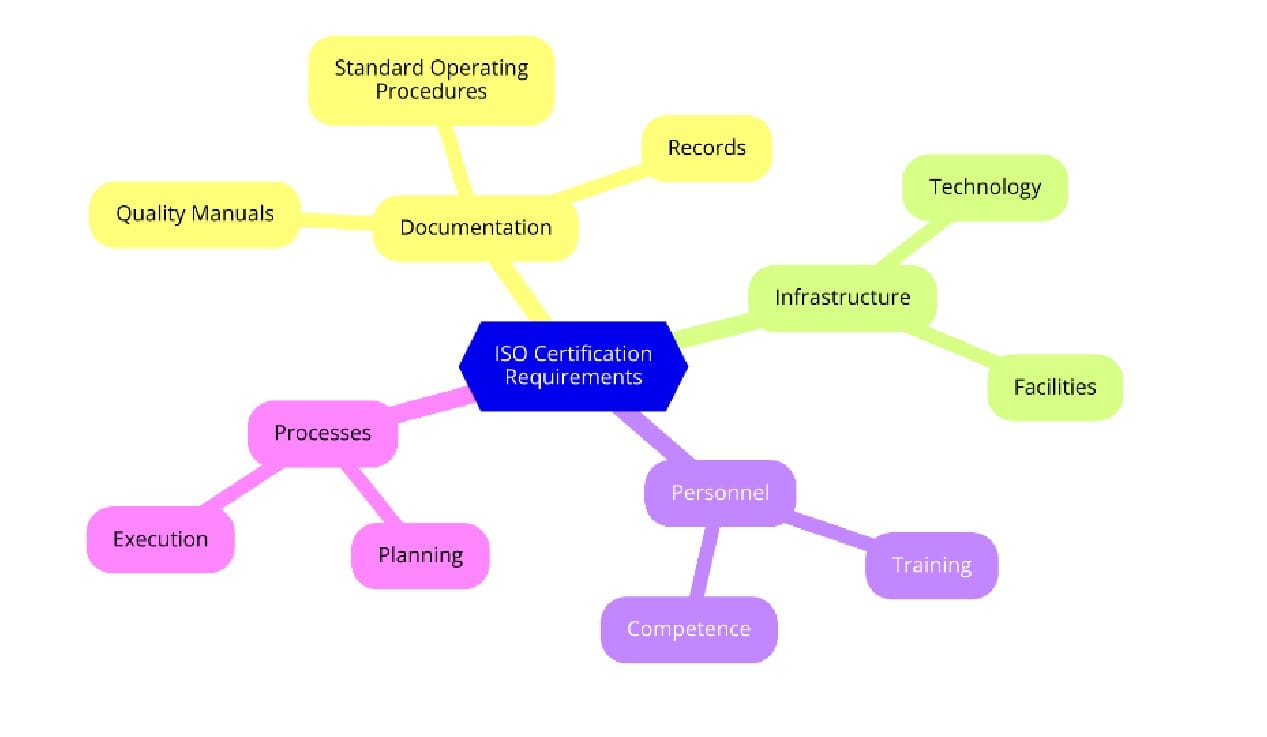

Requirements of ISO Certifications for Motor Vehicle Parts and Accessories Manufacturing

Each ISO standard comes with its own set of requirements that manufacturers must fulfill. Here’s a breakdown of the primary requirements for key certifications:

ISO 9001: Quality Management Systems requirements

- Implementation of a quality management system (QMS)

- Consistent monitoring and documentation of processes

- Regular internal audits and corrective actions

IATF 16949: Automotive Quality Management requirements

- Enhanced defect prevention protocols

- Supplier quality management and development

- Statistical process control and continuous improvement measures

ISO 14001: Environmental Management Systems requirements

- Identification and control of environmental aspects

- Compliance with environmental laws and regulations

- Setting and achieving environmental objectives

ISO 45001: Occupational Health and Safety requirements

- Hazard identification and risk assessment

- Implementation of safety training programs

- Emergency preparedness and incident management

ISO 26262: Functional Safety requirements

- Risk analysis and safety measures for electrical systems

- Functional validation and failure analysis

- Compliance with automotive safety lifecycle requirements

Achieve global recognition with ISO certification for motor vehicle parts manufacturing. Email us at [email protected] or phone +91-8595603096 for professional guidance.

Benefits of ISO Certifications for Motor Vehicle Parts and Accessories Manufacturing

Implementing ISO certifications offers several advantages for manufacturers:

Product Quality: ISO standards ensure that products consistently meet stringent quality criteria, boosting customer satisfaction and loyalty.

Regulatory Compliance: With ISO certifications, manufacturers can seamlessly align with local and international regulations, avoiding penalties and market restrictions.

Market Access: ISO-certified businesses gain credibility and recognition, allowing them to enter new markets and establish partnerships with global automakers.

Efficiency: Streamlined processes and risk management frameworks minimize wastage, reduce costs, and improve productivity.

Sustainability Practices: Standards like ISO 14001 and ISO 50001 help organizations reduce their environmental footprint, aligning with global sustainability goals.

Workplace Safety: ISO 45001 fosters a culture of safety, ensuring employee well-being and reducing workplace accidents.

Market Trends

In 2024, the automotive sector is seeing significant shifts driven by sustainability, automation, and advanced technologies. With the rising adoption of electric vehicles (EVs), ISO 26262 has become more critical than ever for ensuring functional safety in EV components. Additionally, stricter environmental regulations are pushing manufacturers to adopt ISO 14001 and ISO 50001 to meet global emission standards.

As the demand for high-quality and sustainable components grows, ISO certifications are becoming a mandatory requirement for suppliers across the automotive supply chain. Partner with Pacific Certifications to achieve ISO certifications tailored for motor vehicle parts and accessories manufacturing.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Motor Vehicle Parts and Accessories Manufacturing business, please contact us at [email protected] or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs