ISO Certifications for Measurement and Other Scientific Equipment Manufacturing Businesses

ISO certifications are a cornerstone of quality and reliability in the measurement and scientific equipment manufacturing industry. By adopting globally recognized standards, manufacturers can ensure their products meet international benchmarks for accuracy, safety, and performance. These certifications are essential for companies seeking to remain competitive and ensure regulatory compliance.

The measurement and scientific equipment manufacturing sector is critical for industries like healthcare, aerospace, research, and technology. ISO standards provide a framework to ensure that these devices are manufactured with precision and meet stringent quality, safety, and performance requirements.

In today's competitive global market, adherence to ISO standards enables manufacturers to demonstrate their commitment to producing reliable and high-quality equipment. ISO certifications not only address product quality but also emphasize sustainability, environmental management, and organizational efficiency.

Need ISO Certification for Measurement and Scientific Equipment Manufacturing? Contact us at [email protected] or call +91-8595603096 for expert assistance!

Applicable ISO Standards for Measurement and Other Scientific Equipment Manufacturing

Several ISO standards apply to measurement and scientific equipment manufacturing, ensuring that products and processes align with international requirements. Below are the most relevant ISO standards:

1. ISO 9001: Quality Management System (QMS): ISO 9001 is the most widely recognized standard for quality management. It emphasizes customer satisfaction, process improvement, and compliance. For manufacturers, ISO 9001 ensures consistent product quality and efficient production processes.

2. ISO 17025: Testing and Calibration Laboratories: This standard is crucial for manufacturers with in-house calibration and testing facilities. ISO 17025 specifies requirements for the competence, impartiality, and consistent operation of laboratories. It assures clients that the measurements and calibrations meet international accuracy standards.

3. ISO 14001: Environmental Management System (EMS): For environmentally conscious manufacturers, ISO 14001 focuses on reducing environmental impact. It helps organizations manage resources efficiently and meet legal requirements related to environmental sustainability.

4. ISO 13485: Medical Devices QMS: Manufacturers of medical measurement equipment must comply with ISO 13485. It establishes stringent quality management requirements specific to medical devices, ensuring their safety and effectiveness.

5. ISO 45001: Occupational Health and Safety Management: ISO 45001 helps organizations protect their workforce by identifying and mitigating workplace risks. For manufacturers, this standard ensures a safe and compliant working environment.

6. ISO 31000: Risk Management: This standard guides organizations in identifying, assessing, and mitigating risks. In scientific equipment manufacturing, ISO 31000 ensures that potential risks in production or usage are managed effectively.

7. ISO 50001: Energy Management System: Energy efficiency is a priority in modern manufacturing. ISO 50001 helps manufacturers optimize energy use, reduce costs, and minimize carbon emissions.

8. ISO/IEC 17020: Requirements for Inspection Bodies: For manufacturers conducting internal inspections, ISO/IEC 17020 ensures consistent and reliable inspection processes.

Pacific Certifications is a globally recognized certification body specializing in audits and certification issuance. With expertise in ISO standards, we support measurement and scientific equipment manufacturers in achieving certification efficiently and effectively.

Our process includes:

- Conducting audits to ensure compliance with ISO standards.

- Offering guidance throughout the certification process.

- Issuing certifications that are recognized worldwide.

By partnering with Pacific Certifications, manufacturers gain a trusted ally in their pursuit of operational excellence and global competitiveness.

Simplify your ISO certification journey! Reach out to us at [email protected] or speak directly with our team at +91-8595603096.

Requirements of ISO Certifications for Measurement and Other Scientific Equipment Manufacturing

To achieve ISO certification, organizations must fulfill various requirements specific to the standards they are pursuing. Here is an overview:

Requirements For ISO 9001:

- Define and document key processes.

- Establish a quality policy and objectives

- Monitor and measure performance for continual improvement.

Requirements For ISO 17025:

- Prove the competence of laboratory personnel.

- Implement procedures for accurate testing and calibration.

- Maintain traceability and documentation of results.

Requirements For ISO 14001:

- Identify and manage environmental aspects.

- Develop an environmental policy.

- Comply with local environmental regulations.

Requirements For ISO 13485:

- Address risk management and product lifecycle processes

- Ensure compliance with regulatory requirements for medical devices.

Requirements For ISO 45001:

- Conduct hazard identification and risk assessments

- Promote worker involvement in safety programs.

Meeting these requirements demonstrates an organization's ability to consistently deliver products that meet customer and regulatory demands.

Ensure compliance and quality with ISO certification. Contact [email protected] or call +91-8595603096 for expert guidance.

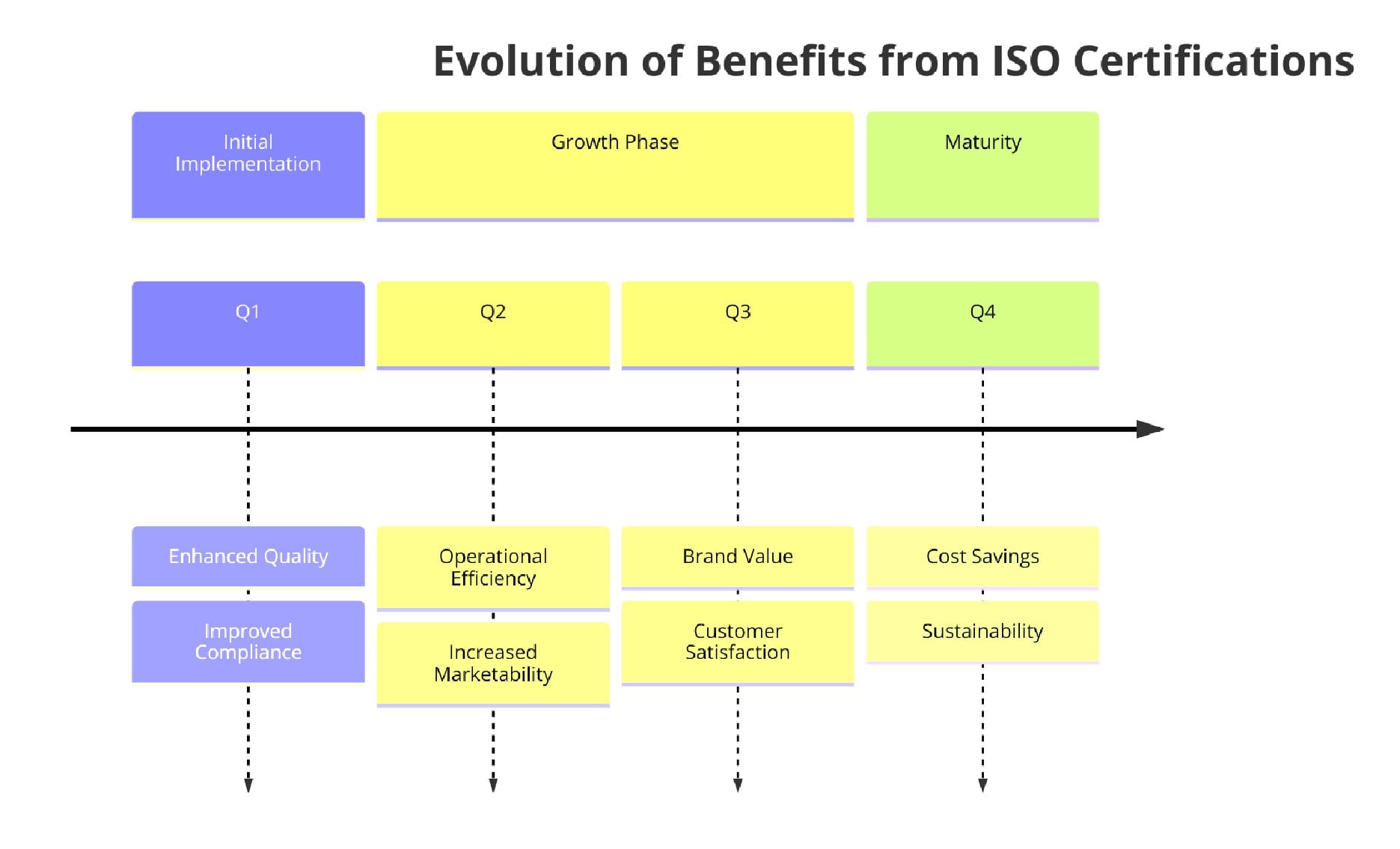

Benefits of ISO Certifications for Measurement and Other Scientific Equipment Manufacturing

ISO certifications offer a plethora of advantages for manufacturers, including:

Quality Assurance: ISO standards ensure consistent product quality, improving customer satisfaction and reducing recalls or defects.

Market Access: Certified organizations gain easier entry into international markets by meeting global benchmarks.

Efficiency: Streamlined processes and reduced wastage lead to higher productivity and cost savings.

Regulatory Compliance: ISO certifications ensure adherence to national and international regulations, reducing legal risks.

Customer Confidence: Certifications demonstrate a commitment to excellence, boosting customer trust and loyalty.

Sustainability: Environmental standards like ISO 14001 promote sustainable practices, aligning with global environmental goals.

Conclusion

As 2024 unfolds, the measurement and scientific equipment manufacturing industry is witnessing significant advancements. According to recent market research, the global demand for precision equipment is projected to grow by 6% annually, driven by innovations in healthcare, renewable energy, and space exploration.

Sustainability is also a key trend, with manufacturers increasingly adopting ISO 14001 to align with global environmental goals. Additionally, automation and digital technologies, including AI-driven calibration systems, are reshaping production processes.

ISO certifications remain vital in this evolving landscape, providing a framework for manufacturers to maintain competitiveness and adapt to changing demands.

Achieving ISO certification can transform your organization, driving quality, compliance, and customer satisfaction. With Pacific Certifications, you gain a partner dedicated to ensuring your success.

Contact Us

Ready to elevate your business? Contact us today to begin your certification journey.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Measurement and Other Scientific Equipment Manufacturing business, please contact us at [email protected] or +91-8595603096.

Read More at: Blogs by Pacific Certifications