ISO Certification for the Manufacturing Sector: Benefits, Challenges, Costs & Common Standards

The manufacturing sector remains one of the preeminent pillars of global economic growth. In the recent years, the sector is under pressure due to global markets and increased competition; adding to this pressure are compliance frameworks, regulatory measures, customer expectations and sustainability considerations. For all manufacturers and the manufacturing sector, consistently delivering product quality, providing a safe workplace and operating in an environmentally responsible manner is not just a priority, but rather, they are critical to growth and viability.

ISO Standards for Manufacturing offer an internationally recognized response to this dilemma. Manufacturers can develop credibility, show accountability and ramp up entry into international markets simply by adopting a structured approach to frameworks. Certification shows that a manufacturer’s operations align with the quality, safety and sustainability criteria increasingly demanded by regulators, customers and global supply chains.

Speak to an auditor at Pacific Certifications, 15-minute call to scope your certification pathway!

Quick summary

ISO Standards for Manufacturering Companies in quality control, workplace safety and sustainability. The most relevant standards include ISO 9001:2015 for quality management, ISO 14001:2015 for environmental responsibility, ISO 45001:2018 for occupational health and safety and ISO/IEC 27001:2022 for data security in digitalized manufacturing systems. This guide outlines requirements, preparation steps, costs and benefits, plus recent trends such as Industry 4.0, sustainability, and integrated management systems for manufacturers.

Introduction

Manufacturing operations are multilayered and multifaceted processes that involve numerous production activities, supply chain coordination, product testing and strict adherence to local and international regulations. Any product quality failure, safety incident or contamination can lead to recalls, harm reputational capital and draw heavy penalties. The ISO standards for manufacturing companies are designed to mitigate these risks by standardizing work systems to improve efficiency or harden work processes against such operational idiosyncrasies.

Why ISO certification matters in manufacturing?

ISO standards for manufacturing companies is critical because it assures customers, regulators and partners that they can expect the same processes and product every time as a manufacturer. Many industries, such as automotive, aerospace, electronics, pharmaceuticals and machinery have strict supply chain requirements that require suppliers to be ISO certified. Certification gives manufacturers access to global markets, allowing manufacturers to effectively compete on a global scale.

While providing trust to customers, ISO certification also helps manufacturers create safer working environments, reduce waste, and manage environmental requirements. It also provides an internal benefit as it dovetails teams towards structured goals, improves efficiencies and mitigates costly error. For organisations trying to set themselves apart in crowded markets, ISO standards for manufacturing companies often becomes a determining factor for winning contracts.

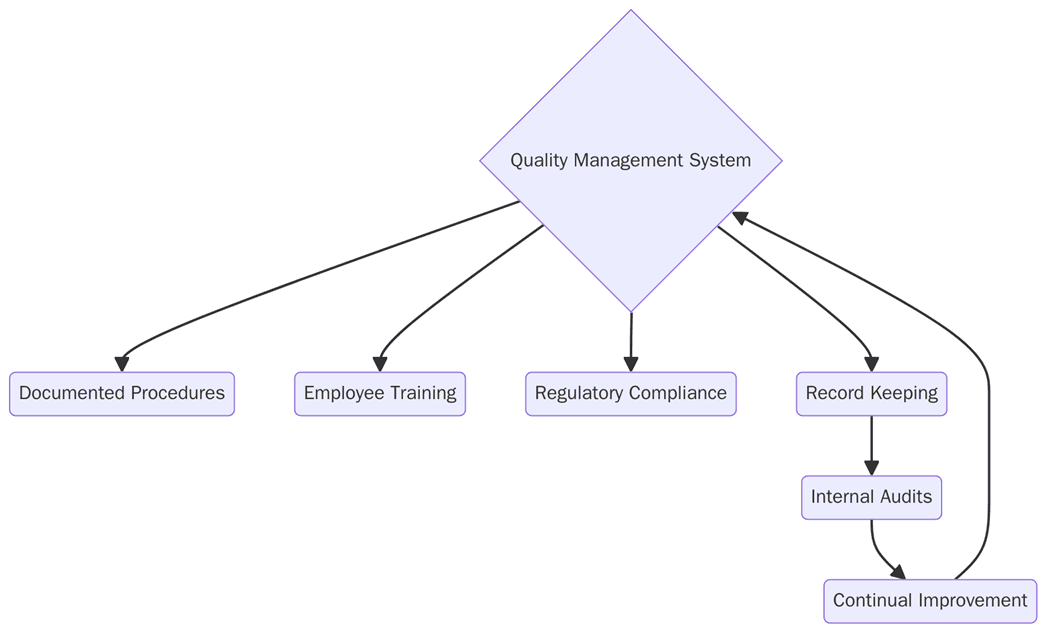

What are the requirements of ISO standards for manufacturing companies?

Manufacturers must establish systems that ensure consistency, quality, and safety across all production stages. The requirements are designed to reduce risks, protect workers and improve accountability. Below are the main requirements:

- Identify the management system boundaries for production process, supply chain or product quality.

- Establish quality, safety, or environmental performance policies depending on the certification.

- Conduct risk assessments and risk controls for all hazards including defective products, machine safety and emissions.

- Train staff on regulatory compliance, machine operation and occupational health and safety practices.

- Establish operational controls including inspections, testing and preventative maintenance.

- Complete internal audits on compliance and evaluate the effectiveness of the system.

- Ensure upper management conducts reviews to evaluate objectives, performance and corrective action.

- Address any nonconformities in a timely fashion to avoid recurrence.

- Support continual improvement by upgrading processes, equipment and safety.

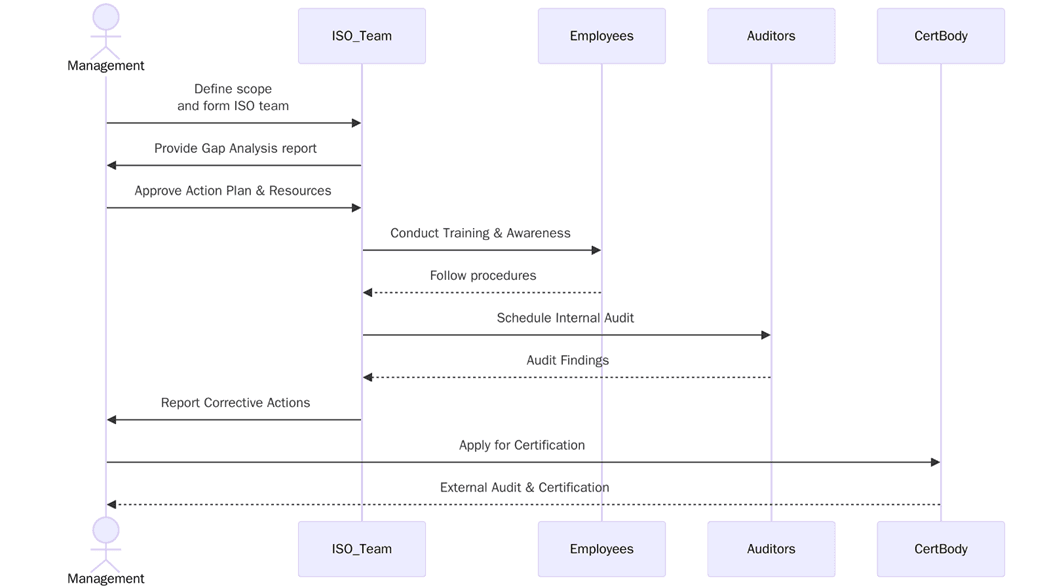

How to prepare for ISO standards for manufacturing companies?

Preparation involves aligning production processes with ISO standards for manufacturing companies and ensuring employees are ready for audits. Below are the steps:

- Conduct a gap analysis to compare existing processes with ISO requirements.

- Develop policies reflecting the organisation’s quality, safety, or sustainability goals.

- Train employees across production and management teams on compliance roles.

- Maintain documented procedures for product testing, machine operation, and supplier management.

- Implement risk management strategies to address workplace hazards and product failures.

- Conduct internal audits and trial reviews before the external certification audit.

- Involve management in reviewing performance indicators and allocating resources.

Certification audit

The certification audit ensures manufacturers meet ISO requirements. It involves the following steps:

Stage 1 audit assesses corporate policies and documentation related to production and compliance records.

Stage 2 audit verifies organisational implementation in production lines, warehouses and safety.

Nonconformities are highlighted and must be dealt with in order to be awarded a certificate.

Management reviews ensure that management is demonstrating their commitment in maintaining these systems.

Certification will be awarded once the gaps have been closed.

Institution will have to undergo an annual surveillance audit to maintain certification status.

Recertification audits must occur every three years.

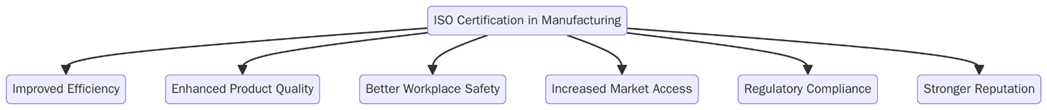

What are the benefits of ISO standards for manufacturing companies?

ISO standards for manufacturing companies bring measurable benefits by improving credibility and strengthening internal systems. In an industry where competition is high and customer demands are rising, the ability to provide consistent quality and reliable operations is essential. Below are the key benefits:

- Better product quality, reducing errors and improving customer satisfaction

- Improved access to global markets by meeting international buyer requirements

- Stronger credibility in supply chain partnerships and contracts

- Reduced workplace accidents through occupational safety systems

- Lower environmental impact through waste reduction and energy efficiency

- Cost savings from fewer defects, recalls and resource inefficiencies

- Increased employee accountability and training, creating a culture of compliance

- Competitive advantage in tenders and industry recognition

Recent trends in ISO Standards for manufacturing companies in 2025

In the recent years, many manufacturers are adopting integrated management systems that combine ISO 9001, ISO 14001, and ISO 45001 to reduce duplication and streamline audits. Sustainability is becoming a major focus, with more companies pursuing ISO 50001 to manage energy use and support environmental goals.

The rise of Industry 4.0 and smart factories has also made ISO/IEC 27001 highly relevant, as manufacturers protect sensitive data from cyber threats. Organisations are increasingly measuring the impact of certification using KPIs such as audit closure times, supplier defect rates, energy consumption per unit produced and customer complaint resolution times. Many are also including SLAs in supplier contracts to ensure timely delivery, product conformity, and quality consistency across the supply chain. Globally, supply chain resilience and ESG expectations are influencing buyers, making ISO standards for manufacturing companies a key differentiator for securing contracts and maintaining long-term competitiveness.

Contact us

Pacific Certifications provides accredited ISO certification services tailored to the manufacturing sector. We work with organisations to assess systems against international standards and certify their quality, safety and sustainability practices. Our role is to provide impartial audits that give manufacturers credibility in competitive markets.

Request your ISO audit plan and fee estimate, we will help you map Stage-1/Stage-2 timelines and evidence requirements for your organisation. Contact us at [email protected] or visit www.pacificcert.com.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs

Author: Alina Ansari