ISO Certifications for Machine Tool and Parts Manufacturing Businesses, Requirements and Benefits

ISO Certifications for Machine Tool and Parts Manufacturing

ISO certifications have become a cornerstone for industries striving to ensure quality, safety, and efficiency. The machine tool and parts manufacturing sector is no exception. By aligning with global standards, manufacturers gain marketing advantage and reassure their customers of their commitment to excellence.

ISO certifications are globally recognized benchmarks for quality management, environmental responsibility, and safety. In the machine tool and parts manufacturing industry, implementing ISO standards is essential to maintain precision, meet customer expectations, and comply with regulatory demands.

The industry involves manufacturing complex parts with high precision. As such, maintaining consistent quality is vital to prevent failures, enhance operational efficiency, and foster customer trust. ISO certifications provide a systematic framework for achieving these objectives while opening doors to global markets.

If you’re aiming for ISO certification in machine tool and parts manufacturing, let us guide your journey toward quality and compliance. Contact us at [email protected] or call +91-8595603096 today!

Applicable ISO Standards for Machine Tool and Parts Manufacturing

Several ISO standards cater to the unique needs of the machine tool and parts manufacturing sector. Below is a list of key standards:

ISO 9001: Quality Management Systems (QMS)

ISO 9001 sets the foundation for ensuring product consistency, quality, and continual improvement. It’s particularly relevant for manufacturers producing high-precision tools and components.

ISO 14001: Environmental Management Systems (EMS)

Sustainability is crucial in today’s industrial landscape. ISO 14001 helps manufacturers minimize environmental impact, manage resources efficiently, and comply with environmental laws.

ISO 45001: Occupational Health and Safety (OHS)

The manufacturing environment involves potential hazards. ISO 45001 ensures worker safety, reduces workplace risks, and fosters a healthier work culture.

ISO 50001: Energy Management Systems

Energy efficiency is a priority in modern manufacturing. ISO 50001 guides manufacturers in optimizing energy use, cutting costs, and contributing to a sustainable future.

ISO 13485: Quality Management for Medical Devices

For manufacturers producing parts for medical tools or devices, ISO 13485 is essential. It ensures compliance with strict regulatory requirements in the healthcare sector.

This standard is critical for manufacturers aiming to mitigate risks, enhance decision-making, and protect their operations from unforeseen disruptions.

ISO 27001: Information Security Management

As manufacturing integrates advanced technologies and data systems, protecting sensitive information is crucial. ISO 27001 safeguards data from cyber threats and breaches.

ISO 10012: Measurement Management Systems

Accurate measurement is indispensable in precision manufacturing. ISO 10012 ensures the proper calibration and maintenance of measurement tools.

Click here to find out more applicable standards to your industry

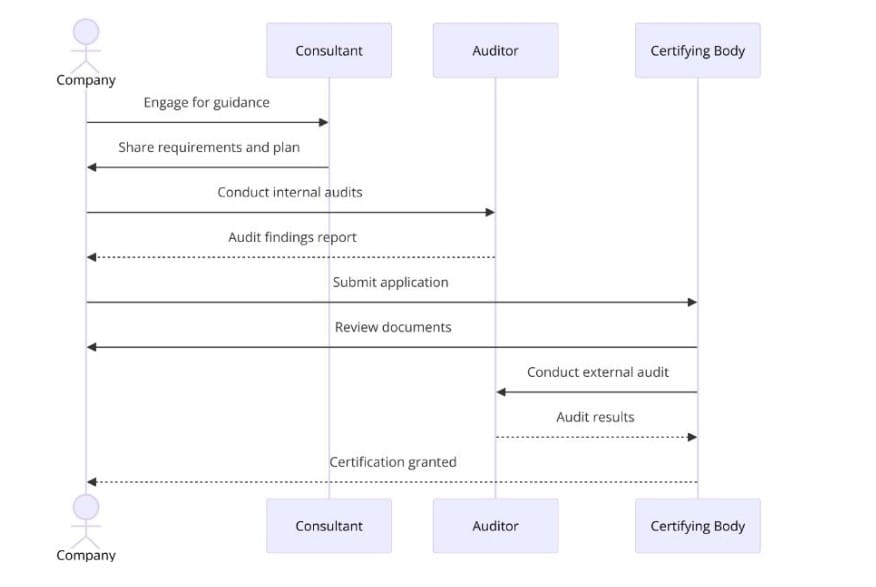

At Pacific Certifications, we specialize in conducting audits and issuing ISO certifications to support your journey toward excellence. We work with machine tool and parts manufacturers to evaluate their compliance with ISO standards, ensuring they meet industry benchmarks effectively. Our expertise lies in delivering impartial and comprehensive certification services that instill trust and credibility.

Our process involves:

- Conducting rigorous audits to assess adherence to ISO requirements.

- Providing detailed reports to highlight areas of conformity.

- Issuing ISO certifications to validate your commitment to quality and compliance.

For professional ISO certification services tailored to machine tool and parts manufacturing, email [email protected] or contact us at +91-8595603096.

Requirements of ISO Certifications for Machine Tool and Parts Manufacturing

ISO standards have specific requirements tailored to ensure quality, safety, efficiency, and sustainability. Below are the requirements outlined for each standard applicable to machine tool and parts manufacturing.

ISO 9001: Quality Management Systems (QMS)

- Customer Focus: Understand and meet customer needs while exceeding expectations.

- Leadership Commitment: Demonstrate top management’s involvement and accountability.

- Process Approach: Manage interrelated processes effectively for streamlined operations.

- Risk-Based Thinking: Identify and address risks and opportunities.

- Continual Improvement: Regularly enhance products, services, and processes.

- Performance Monitoring: Set measurable objectives and evaluate results periodically.

ISO 14001: Environmental Management Systems (EMS)

- Environmental Policy: Develop and communicate an organization-wide commitment to sustainability.

- Impact Assessment: Identify and evaluate environmental impacts associated with operations.

- Legal Compliance: Adhere to relevant environmental regulations and standards.

- Resource Efficiency: Optimize energy, water, and raw material usage.

- Emergency Preparedness: Plan for and respond to environmental emergencies effectively.

ISO 45001: Occupational Health and Safety Management Systems

- Hazard Identification: Assess risks and control hazards in the workplace.

- Worker Participation: Engage employees in safety initiatives and decision-making processes.

- Legal and Regulatory Compliance: Meet applicable health and safety legislation.

- Incident Reporting: Establish systems to report, investigate, and learn from workplace incidents.

- Preventive Actions: Implement measures to prevent workplace injuries and illnesses.

ISO 50001: Energy Management Systems

- Energy Review: Conduct assessments to understand energy usage patterns.

- Objectives and Targets: Set goals for energy efficiency improvement.

- Operational Control: Establish controls to ensure efficient energy use.

- Energy Performance Indicators (EnPIs): Measure and monitor energy performance.

- Management Review: Periodically evaluate the energy management system for effectiveness.

By fulfilling these requirements, machine tool and parts manufacturers can secure ISO certifications and achieve operational excellence, enhance market reputation, and meet customer and regulatory demands effectively.

Strengthen your market position with ISO certification. Connect with us at [email protected] or dial +91-8595603096 to start your certification process.

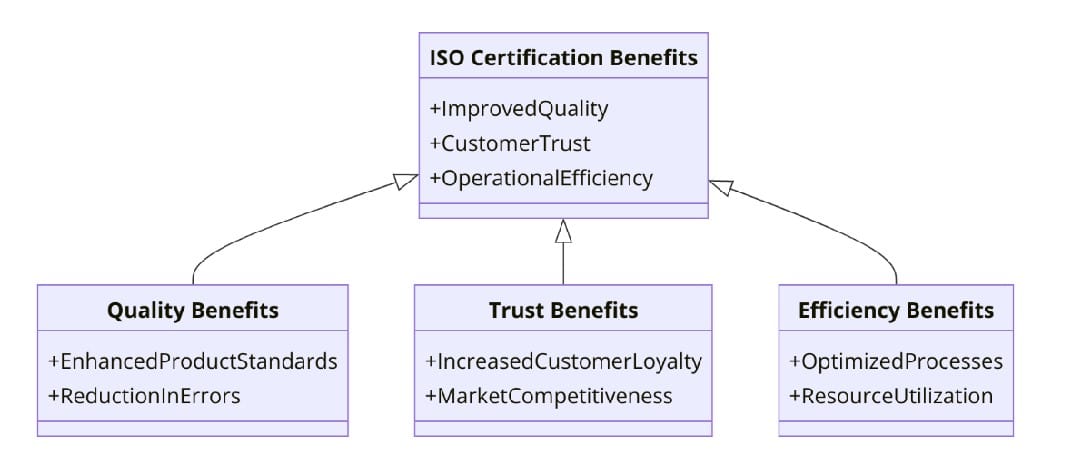

Benefits of ISO Certifications for Machine Tool and Parts Manufacturing

ISO certifications bring numerous advantages that significantly enhance a manufacturer's reputation, efficiency, and market position.

- Quality: With ISO 9001, manufacturers can consistently deliver products that meet customer expectations and industry specifications.

- Safety: ISO 45001 ensures safer work environments, reducing accidents and boosting employee morale.

- Cost Efficiency: Standards like ISO 14001 and ISO 50001 optimize resource use, minimize waste, and lower production costs.

- Global Market Access: ISO certifications are often prerequisites for doing business internationally, allowing manufacturers to expand their reach.

- Customer Confidence: ISO certifications signal a commitment to quality and responsibility, increasing trust and customer loyalty.

- Regulatory Compliance: Adherence to ISO standards helps manufacturers stay ahead of regulatory changes, avoiding fines and penalties.

In 2024, the machine tool and parts manufacturing industry is seeing rapid advancements due to Industry 4.0 technologies like AI, IoT, and automation. These technologies demand higher standards for precision, data security, and energy efficiency, making ISO certifications more relevant than ever.

Reports indicate that manufacturers with ISO certifications are better positioned to integrate smart technologies and meet emerging challenges, reinforcing the importance of adhering to global standards.

Are you ready to take your manufacturing processes to the next level? Achieve global recognition and operational excellence with ISO certifications from Pacific Certifications. Partner with us to secure your place as an industry leader.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Machine Tool and Parts Manufacturing business, please contact us at [email protected] or +91-8595603096.

FAQs: ISO Certifications for Machine Tool and Parts Manufacturing

What are the main ISO standards for machine tool and parts manufacturing?

Key standards include ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational safety.

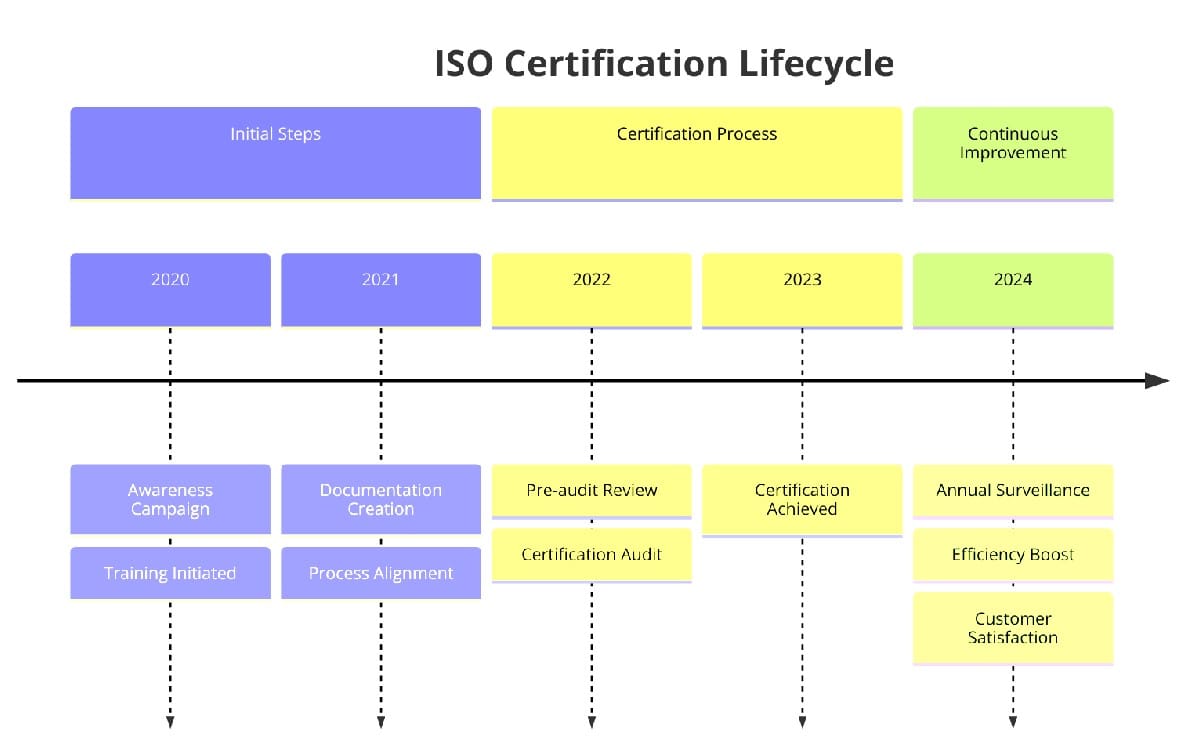

How long does the ISO certification process take?

The timeframe varies based on the organization’s readiness and complexity but typically takes a few months, including audits and documentation reviews.

Why is ISO 9001 important for manufacturers?

ISO 9001 ensures consistent quality and continual improvement, which are critical for maintaining precision and customer satisfaction.

Can Pacific Certifications provide consultancy for ISO standards?

No, Pacific Certifications focuses solely on audits and issuing certifications, ensuring impartiality and compliance with industry norms.

What are the costs associated with ISO certification?

Certification costs depend on factors like company size, industry, and scope of certification. Contact us for a customized quote.

Is ISO certification mandatory?

While not always mandatory, ISO certifications are often required to meet customer demands, enter global markets, and comply with industry regulations.

Read More at: Blogs by Pacific Certifications