ISO Certifications for Household Appliance Manufacturing Businesses, Requirements and Benefits

ISO Certifications for Household Appliance Manufacturing

ISO standards have become a cornerstone for quality assurance and operational excellence across industries. For household appliance manufacturers, implementing these internationally recognized standards ensures product safety, quality and customer satisfaction.

ISO standards are developed to provide frameworks that help organizations ensure consistency, safety, and quality in their operations. For household appliance manufacturing, these standards are particularly crucial due to the direct impact of appliances on consumer safety and daily life.

From energy efficiency to environmental responsibility, ISO standards cover every aspect of appliance production. These standards also reflect the growing consumer demand for sustainable and safe household products, making certification a competitive advantage in the global market.

If you're looking to enhance product quality and safety through ISO certification for household appliance manufacturing, contact us at [email protected] or call +91-8595603096 for expert assistance.

Applicable ISO Standards for Household Appliance Manufacturing

Understanding which ISO standards apply to your operations is the first step toward certification. Below are the most relevant ISO standards for the household appliance manufacturing sector:

ISO 9001:2015 Quality Management Systems (QMS)

ISO 9001 is the most widely adopted standard for quality management. It ensures that household appliances meet customer and regulatory requirements while fostering continuous improvement in processes.

ISO 14001: Environmental Management Systems (EMS)

This standard addresses environmental impact by guiding manufacturers to implement sustainable practices, minimize waste, and manage energy consumption responsibly.

ISO 45001: Occupational Health and Safety Management Systems

Safety is paramount in manufacturing. ISO 45001 helps manufacturers create safer working environments, reducing workplace accidents and ensuring compliance with health and safety regulations.

ISO 50001: Energy Management Systems

Energy efficiency is critical for reducing operational costs and environmental impact. ISO 50001 helps household appliance manufacturers optimize energy use throughout the production lifecycle.

ISO 26000: Social Responsibility

Though not certifiable, ISO 26000 provides guidance on social responsibility, promoting ethical practices and accountability in manufacturing operations.

ISO 13485: Quality Management Systems for Medical Devices

If manufacturing appliances with medical applications, this standard ensures product safety, reliability, and regulatory compliance specific to healthcare needs.

ISO 17025: Testing and Calibration Laboratories

For manufacturers with in-house testing labs, ISO 17025 ensures accuracy, reliability, and consistency in testing and calibration processes.

Click here to find out more applicable standards to your industry

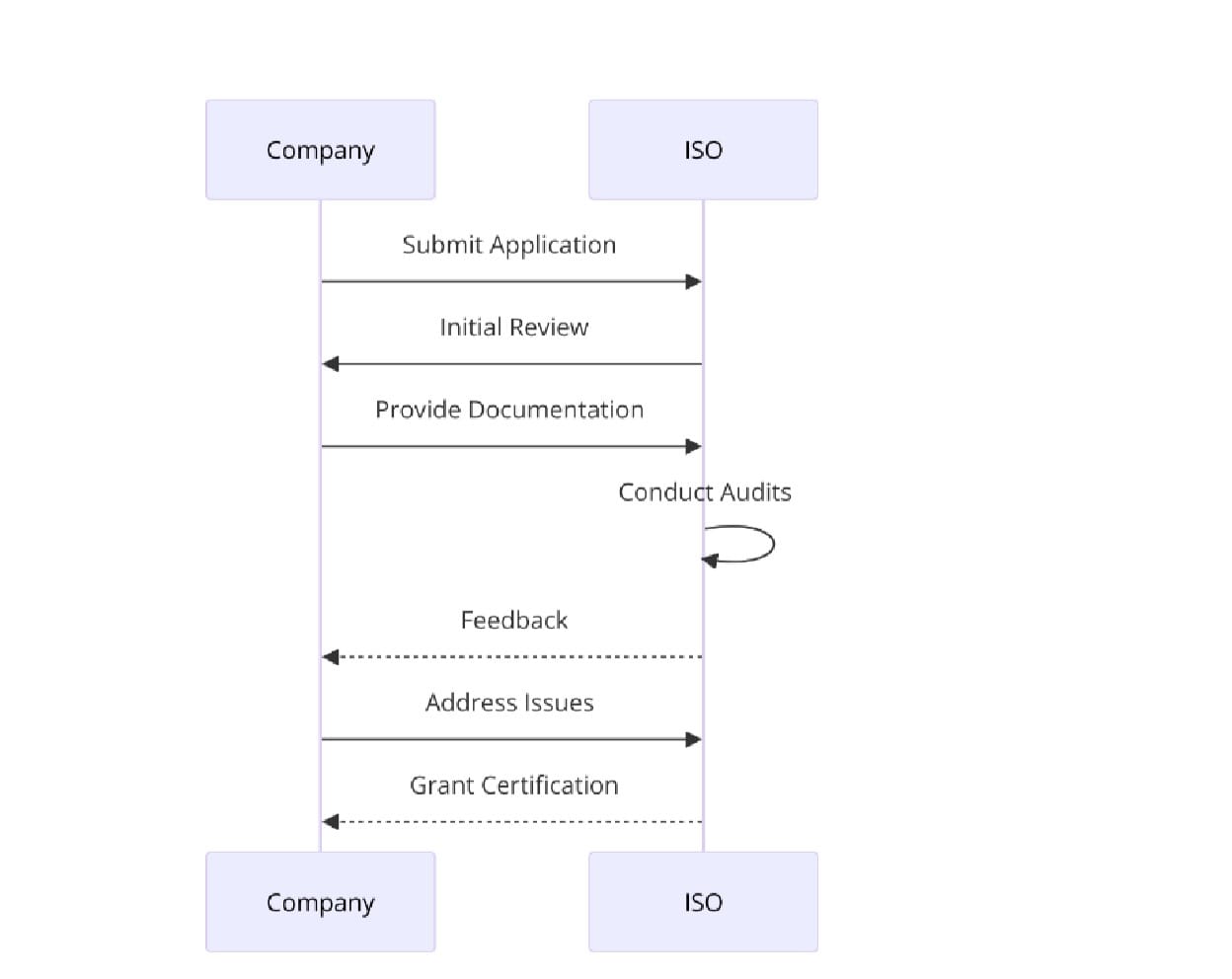

At Pacific Certifications, we specialize in auditing and issuing ISO certifications for household appliance manufacturers. Our team of expert auditors ensures a seamless certification process by assessing your compliance with applicable standards.

We work with integrity and professionalism, delivering results that reflect your commitment to quality and compliance. Whether you're seeking ISO 9001, ISO 14001 etc, we provide tailored services to meet your needs.

Stand out in the market with ISO certifications tailored for household appliance manufacturers. Contact us at [email protected] or call +91-8595603096 for more information.

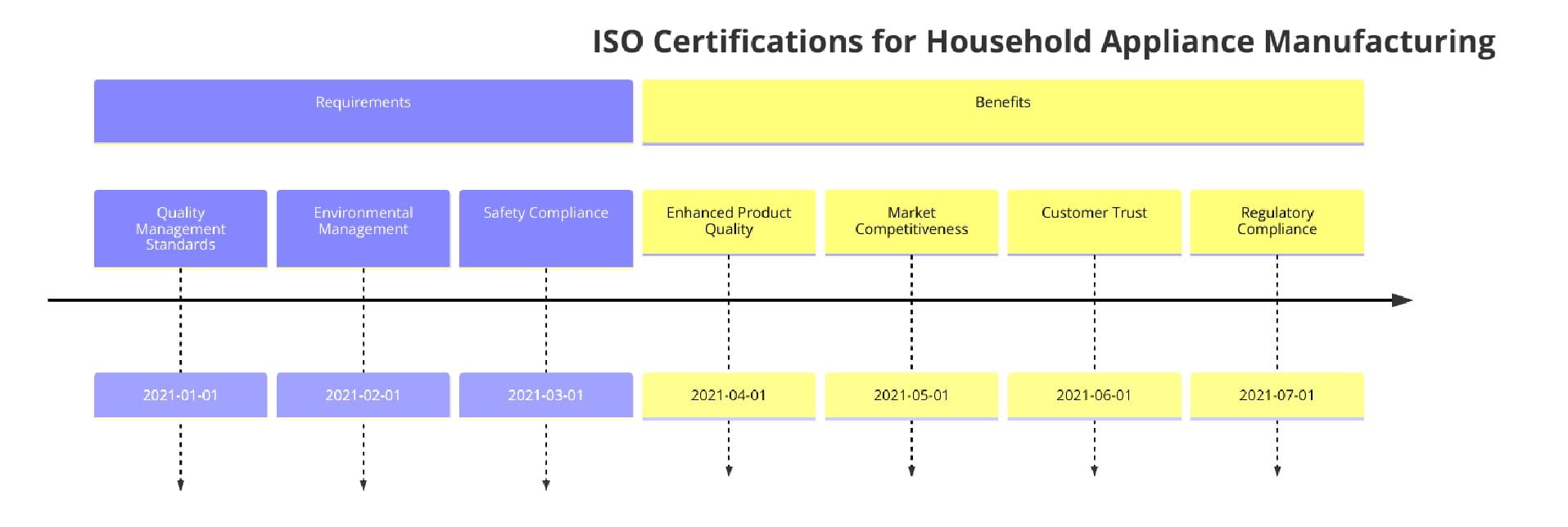

Requirements of ISO Certifications for Household Appliance Manufacturing

ISO 9001: Quality Management Systems (QMS) Requirements

- Establish a Quality Management System (QMS): Create a structured QMS that defines policies, processes, and procedures for quality control.

- Customer Focus: Ensure that products meet customer expectations and regulatory requirements.

- Leadership Commitment: Top management must demonstrate involvement and accountability in maintaining the QMS.

- Risk-Based Thinking: Identify and address risks and opportunities to improve product quality.

- Regular Audits and Performance Evaluation: Monitor and measure processes to ensure the QMS is effective.

ISO 14001: Environmental Management Systems (EMS) Requirements

- Environmental Policy: Develop and implement a policy that reflects the organization’s commitment to environmental protection.

- Environmental Aspect Identification: Identify and assess the environmental aspects of manufacturing activities.

- Legal Compliance: Comply with applicable environmental laws and regulations.

- Setting Environmental Objectives: Establish measurable goals to minimize waste, emissions, and resource consumption.

- Monitoring and Reporting: Regularly evaluate environmental performance to ensure objectives are met.

ISO 45001: Occupational Health and Safety Management Systems Requirements

- Health and Safety Policy: Establish a framework to manage workplace health and safety hazards.

- Hazard Identification and Risk Assessment: Identify potential workplace hazards and assess their risks.

- Employee Involvement: Engage employees in health and safety initiatives and provide adequate training.

- Incident Management: Implement procedures for reporting, investigating, and addressing workplace incidents.

- Continuous Improvement: Regularly monitor and improve the occupational health and safety management system.

ISO 50001: Energy Management Systems Requirements

- Energy Policy: Create a policy that outlines the organization’s commitment to energy efficiency.

- Energy Baseline and Objectives: Identify the current energy usage and set measurable energy-saving targets.

- Energy Performance Indicators (EnPIs): Develop metrics to track and improve energy performance.

- Monitoring and Measurement: Regularly measure energy consumption and implement corrective actions to achieve objectives.

ISO 17025: Testing and Calibration Laboratories Requirements

For manufacturers with in-house testing labs, ISO 17025 ensures accurate and reliable testing processes. Requirements include:

- Competency of Personnel: Ensure lab staff are qualified and trained to perform testing and calibration.

- Equipment Calibration: Use calibrated and well-maintained equipment for all measurements.

- Method Validation: Validate testing methods to ensure they are reliable and appropriate.

- Accurate Record-Keeping: Maintain detailed records of testing procedures and results.

By meeting these requirements, household appliance manufacturers can achieve compliance with international standards, ensuring quality, safety, and sustainability in their operations.

Meet global standards with ISO certifications. Connect with us at [email protected] or via phone at +91-8595603096 to start your certification journey.

Benefits of ISO Certifications for Household Appliance Manufacturing

Achieving ISO certification offers a wide range of benefits for manufacturers in the household appliance sector:

Product Quality:

ISO standards ensure that appliances meet high-quality benchmarks, fostering customer trust and loyalty.

Regulatory Compliance:

Compliance with international standards reduces the risk of legal penalties and ensures smooth market access globally.

Marketing Advantage:

Certified manufacturers stand out in the market, gaining a competitive edge over non-certified competitors.

Operational Efficiency: Implementing ISO standards often leads to streamlined processes, reducing waste and increasing productivity.

Sustainability:

With standards like ISO 14001 and ISO 50001, manufacturers can significantly reduce their environmental impact.

Employee Morale:

ISO standards like ISO 45001 promote a safer workplace, boosting employee morale and productivity.

Market Trends

In 2024, the global household appliance market continues to witness significant transformations. Sustainability and energy efficiency remain key trends, with more consumers demanding eco-friendly appliances.

ISO certifications are playing a pivotal role in addressing these trends. For instance, ISO 50001 is helping manufacturers reduce energy consumption, while ISO 14001 supports environmental sustainability. Furthermore, governments worldwide are implementing stricter regulations, making ISO compliance a necessity rather than an option.

These developments highlight the growing importance of ISO certifications in shaping the future of household appliance manufacturing.

Contact Us

If you’re ready to elevate your household appliance manufacturing operations with ISO certifications, Pacific Certifications is here to guide you. Our expert auditors will ensure a smooth certification process, helping you achieve compliance with globally recognized standards.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Household Appliance Manufacturing business, please contact us at [email protected] or +91-8595603096.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs