ISO Certifications for Gold and Non-Ferrous Metal Processing Businesses

ISO Certifications for Gold and Non-Ferrous Metal Processing

Gold and other non-ferrous metals are essential in industries ranging from jewelry and electronics to automotive manufacturing. Ensuring consistent quality and sustainability in processing these materials is crucial, not just for compliance but also for gaining a marketing value in global markets. This is where ISO certifications play a pivotal role.

ISO provides a framework for standardizing operations, minimizing environmental impact, and enhancing customer trust. These globally recognized standards enable companies to demonstrate their commitment to excellence while addressing specific challenges unique to gold and non-ferrous metal processing.

Whether you deal in refining, smelting, or alloy production, adhering to ISO standards ensures optimized processes and safer working conditions. With the 2024 market trends indicating stricter regulations and a growing emphasis on sustainable sourcing, ISO certifications have never been more critical.

Looking for ISO certification for Gold and Other Non-Ferrous Metal Processing? Contact us at [email protected] or call us at +91-8595603096 for expert assistance.

Applicable ISO Standards for Gold and Other Non-Ferrous Metal Processing

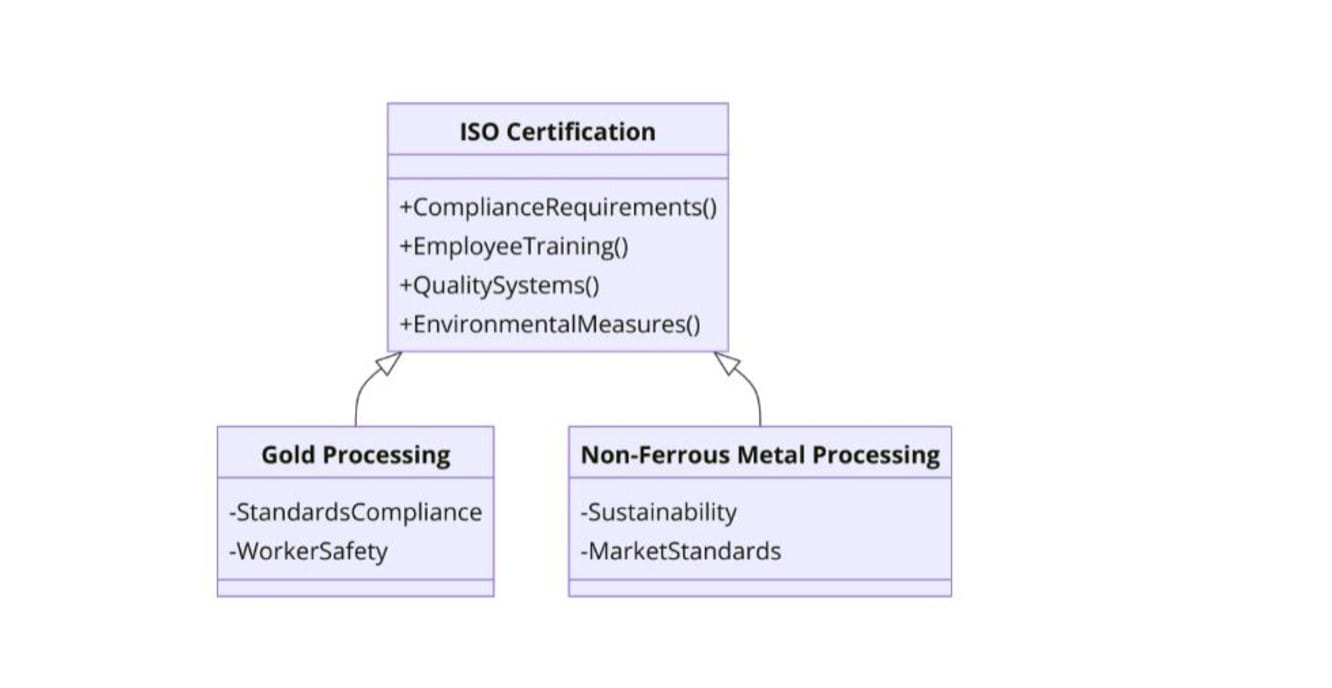

Several ISO standards cater to the intricate requirements of gold and non-ferrous metal processing. Below are the most applicable ones:

ISO 9001: Quality Management Systems (QMS)

This standard ensures organizations maintain consistent quality in their operations and output. For gold and non-ferrous metals, it emphasizes process optimization, defect prevention, and customer satisfaction.

ISO 14001: Environmental Management Systems (EMS)

Processing metals can have significant environmental implications. ISO 14001 helps organizations identify and control their environmental impact through sustainable practices, waste reduction, and pollution prevention.

ISO 45001: Occupational Health and Safety Management Systems

With gold and non-ferrous metal processing involving high-risk activities, ISO 45001 prioritizes employee safety. It focuses on hazard identification, risk mitigation, and fostering a safe workplace culture.

ISO 17025: Testing and Calibration Laboratories

This standard is critical for laboratories analyzing the purity and composition of metals. It ensures accurate results through robust testing and calibration protocols.

ISO 50001: Energy Management Systems

Processing metals is energy-intensive. ISO 50001 helps organizations reduce energy consumption, increase efficiency, and achieve cost savings without compromising output quality.

ISO 31000: Risk Management

Risk management is central to industries dealing with precious and non-ferrous metals. ISO 31000 provides a structured approach to identifying, assessing, and mitigating operational risks.

Click here to find out more applicable standards to your industry

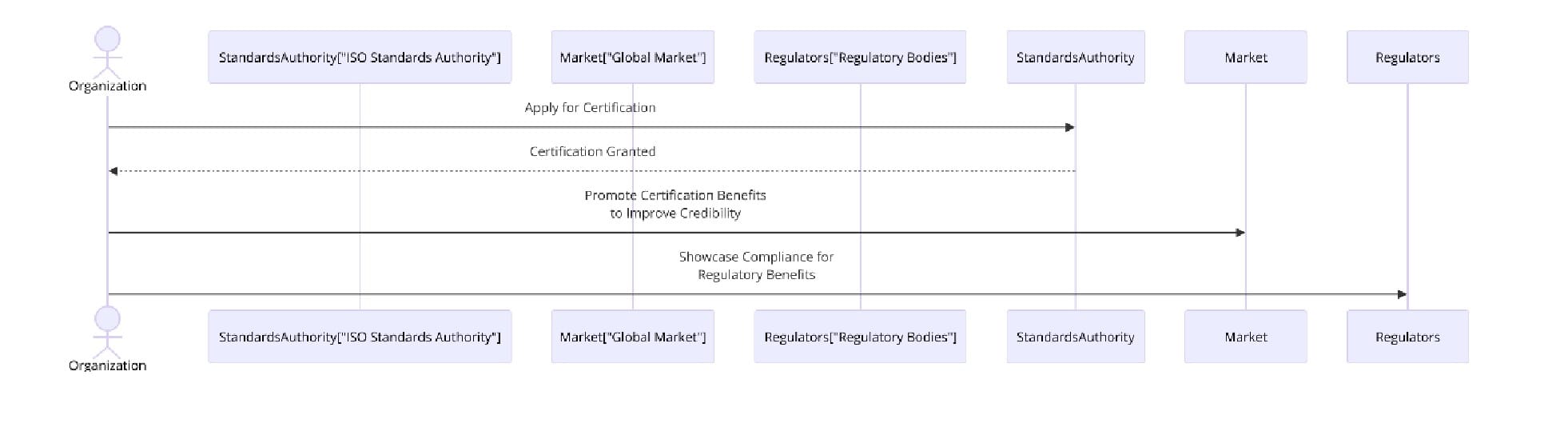

At Pacific Certifications, we specialize in conducting audits and issuing ISO certifications tailored to the gold and non-ferrous metal processing industries. Our certification services are designed to provide companies with the assurance that their systems meet international benchmarks.

Our team of skilled auditors ensures a seamless process, offering guidance on compliance with standards such as ISO 9001, ISO 14001, and ISO 45001. With extensive experience across various sectors, we bring a deep understanding of the unique challenges and opportunities in the metals industry.

Partnering with Pacific Certifications means aligning your business with global best practices and boosting credibility in the eyes of stakeholders and customers.

Ready for ISO certification in Gold and Non-Ferrous Metal Processing?

Email [email protected] or call +91-8595603096 to get started.

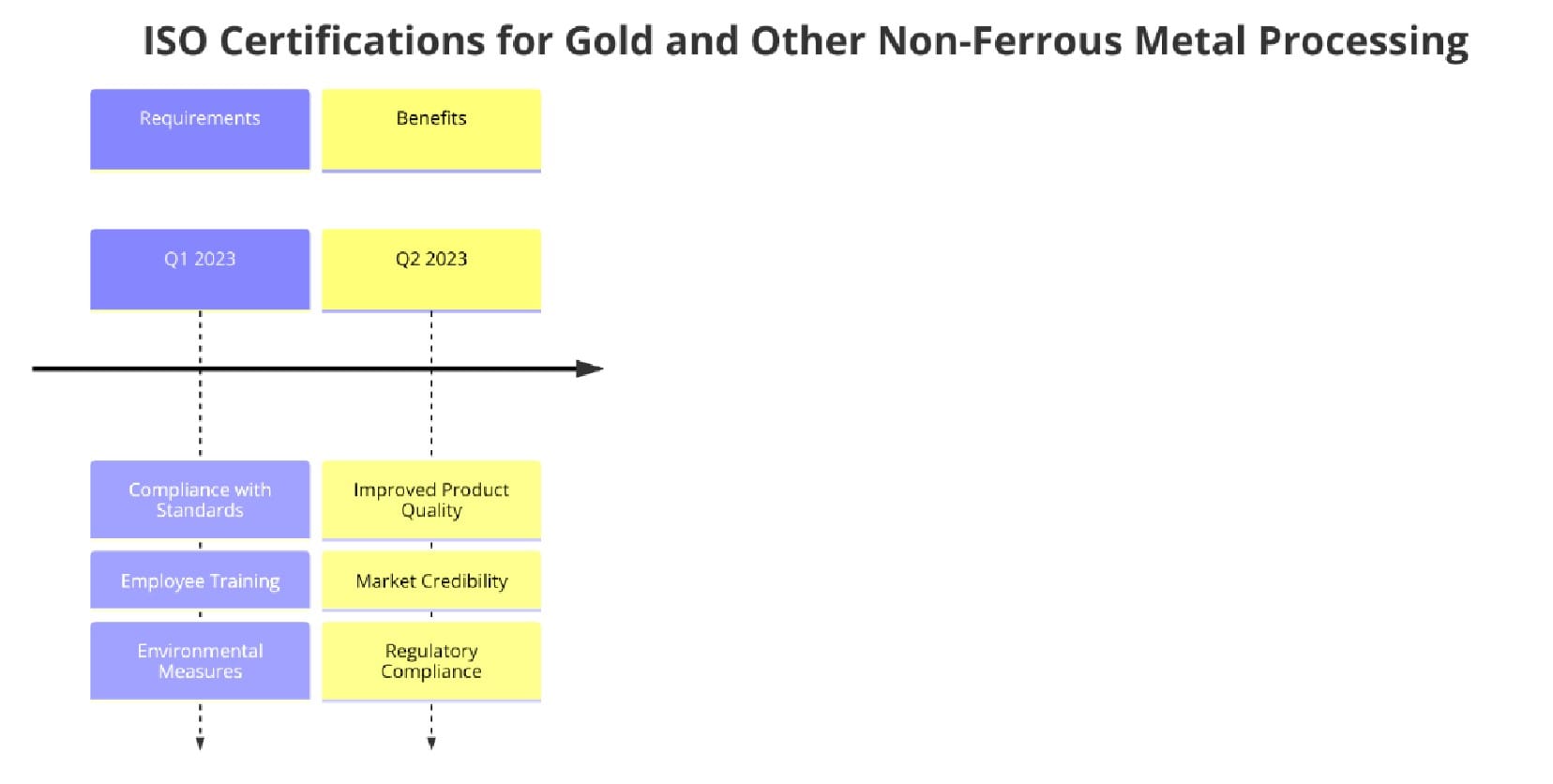

Requirements of ISO Certifications for Gold and Other Non-Ferrous Metal Processing

ISO certifications come with a structured set of requirements that companies need to fulfill. Here’s a closer look at some key elements for various standards:

ISO 9001 Requirements

- Clear documentation of processes and workflows

- Regular quality checks and corrective measures

- Focus on customer satisfaction and continuous improvement

ISO 14001 Requirements

- Identification of environmental risks and impacts

- Implementation of sustainable practices like recycling and energy efficiency

- Monitoring and reducing emissions and waste

ISO 45001 Requirements

- Comprehensive risk assessments of workplace hazards

- Training programs for employee health and safety awareness

- Emergency preparedness and response protocols

ISO 50001 Requirements

- Energy audits and performance benchmarking

- Integration of energy-efficient technologies

- Regular monitoring and reporting of energy usage

ISO 17025 Requirements

- Calibration of testing equipment

- Competence in performing precise analyses of gold and metal compositions

- Adherence to traceability and reporting norms

ISO 31000 Requirements

- Strategic risk evaluation methods

- Proactive mitigation plans for supply chain, operational, and market risks

- Development of a resilient organizational framework

Streamline your path to ISO certification. Contact our team at [email protected] or +91-8595603096 for a seamless experience!

Benefits of ISO Certifications for Gold and Non-Ferrous Metal Processing

Adopting ISO certifications delivers transformative benefits that extend across the organization. Some key advantages include:

Product Quality: ISO standards like ISO 9001 ensure that every stage of metal processing aligns with stringent quality requirements, resulting in high-grade outputs.

Environmental Responsibility: With ISO 14001, companies can reduce their carbon footprint, minimize waste, and adopt greener practices, which are increasingly demanded by global customers and regulators.

Safer Workplaces: By adhering to ISO 45001, organizations can safeguard their workforce, reduce accidents, and improve overall productivity.

Energy Efficiency: ISO 50001 fosters smarter energy use, helping companies save costs and align with sustainability goals.

Market Credibility: ISO certifications signal a commitment to excellence and compliance, giving companies a competitive edge in both domestic and international markets.

Regulatory Compliance: ISO-certified companies are better positioned to meet legal and regulatory requirements, avoiding penalties and reputational risks.

Risk Management and Business Continuity: Standards like ISO 31000 and ISO 22301 ensure that organizations can navigate challenges effectively, securing long-term operational stability.

In 2024, the gold and non-ferrous metal industry is witnessing a surge in demand driven by advancements in renewable energy technologies and electric vehicles. With global regulations tightening on environmental compliance, companies are prioritizing ISO certifications to remain competitive.

Research highlights an increased focus on circular economies, where recycled metals play a significant role. Certifications such as ISO 14001 are essential for businesses aiming to align with these evolving market dynamics. Industry leaders emphasize the importance of adopting ISO standards to future-proof operations amidst rapidly changing consumer expectations and regulatory landscapes.

Are you ready to elevate your gold or non-ferrous metal processing operations? Let Pacific Certifications guide you through the process of obtaining globally recognized ISO certifications.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Gold and Other Non-Ferrous Metal Processing business, please contact us at [email protected] or +91-8595603096.

FAQs: ISO Certifications for Gold and Other Non-Ferrous Metal Processing

What is the significance of ISO certifications in metal processing?

ISO certifications provide a framework for ensuring quality, safety, and sustainability in metal processing. They enhance market credibility and operational efficiency.

Which ISO standards are most relevant for gold processing?

ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Health and Safety) are among the most applicable standards for gold and non-ferrous metal processing.

How does ISO 50001 help in metal processing?

ISO 50001 promotes energy-efficient practices, helping organizations reduce costs while maintaining operational performance.

Can Pacific Certifications assist with ISO implementation?

No, Pacific Certifications focuses exclusively on auditing and issuing certifications. We do not provide implementation or consultancy services.

Is ISO certification mandatory for metal processing businesses?

While not mandatory, ISO certifications are highly recommended for businesses aiming to meet international standards, enhance quality, and gain customer trust.

How long does the ISO certification process take?

The timeline varies depending on the organization's size, complexity, and readiness. Pacific Certifications ensures a streamlined and efficient process.

Read More at: Blogs by Pacific Certifications