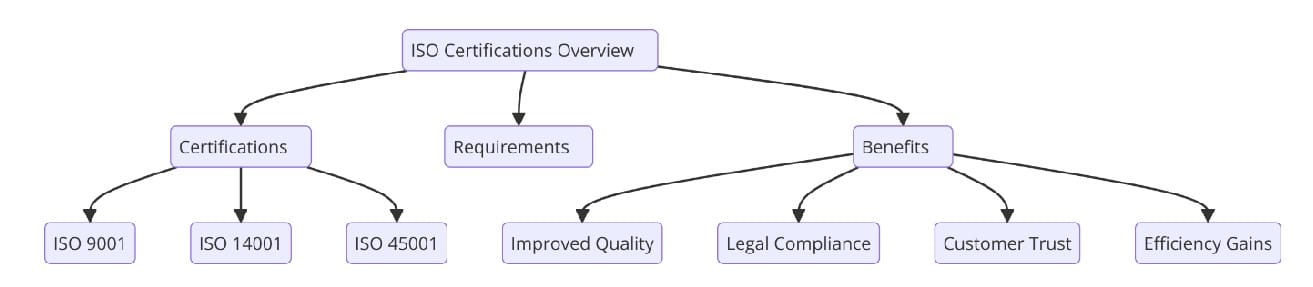

ISO Certifications for Glass and Glass Product Manufacturing Businesses, Requirements and Benefits

ISO Certifications for Glass and Glass Product Manufacturing

The glass and glass product manufacturing industry plays a critical role in construction, automotive, technology, and packaging sectors. Ensuring the quality and safety of these products is a growing priority, and ISO standards have emerged as the cornerstone of achieving these goals.

ISO certifications for glass manufacturing provide a globally recognized framework for enhancing product quality, improving efficiency & meeting customer expectations. By adopting these standards, manufacturers can align with international best practices in the market.

If you're seeking ISO certification for Glass and Glass Product Manufacturing, we’re here to help! Contact us at [email protected] or call +91-8595603096 to get started.

Applicable ISO Standards for Glass and Glass Product Manufacturing

ISO certifications cover various aspects of quality, safety, environmental sustainability, and energy efficiency. Here are some key ISO standards relevant to the glass industry:

1. ISO 9001: Quality Management System (QMS): ISO 9001 establishes guidelines to ensure consistent product quality and customer satisfaction. It applies to all stages of glass manufacturing, from raw material sourcing to the final product.

2. ISO 14001: Environmental Management System (EMS): This standard focuses on minimizing environmental impact, addressing waste management, energy consumption, and emissions. Glass manufacturers adopting ISO 14001 can demonstrate their commitment to sustainability.

3. ISO 50001: Energy Management System (EnMS): Energy-intensive industries like glass manufacturing benefit greatly from ISO 50001, which provides a systematic approach to optimizing energy use, reducing costs, and decreasing carbon footprints.

4. ISO 45001: Occupational Health and Safety Management System (OH&S): Glass production involves handling hazardous materials and high-temperature processes. ISO 45001 ensures worker safety through effective risk management and a safe working environment.

5. ISO 22000: Food Safety Management System: For glass products used in food and beverage packaging, ISO 22000 ensures compliance with food safety standards and helps maintain consumer trust.

6. ISO 16949: Quality Management System for Automotive Suppliers: This standard is vital for glass manufacturers supplying products to the automotive industry. It ensures that glass products meet strict automotive quality and safety requirements.

7. ISO 28000: Security Management Systems for the Supply Chain: For glass products with complex supply chains, ISO 28000 addresses security risks, ensuring safe and uninterrupted supply chain operations.

Click here to find out more applicable standards to your industry

Pacific Certifications specializes in providing auditing and certification services to help glass manufacturers achieve compliance with applicable ISO standards. Our expertise ensures a seamless certification process, enabling businesses to unlock new opportunities in both domestic and international markets.

Whether it’s ISO 9001 for quality management or ISO 14001 for environmental compliance, our auditors ensure a thorough and transparent evaluation to confirm your adherence to global standards.

Looking for ISO certification for your glass manufacturing business? Email us at [email protected] or phone us at +91-8595603096 to discuss your requirements.

Requirements of ISO Certifications for Glass and Glass Product Manufacturing

Each ISO standard outlines specific requirements that manufacturers must meet to achieve certification. Below are some common requirements across key standards:

ISO 9001 Requirements

- Development of a quality management policy

- Regular quality audits and performance evaluations

- Continuous process improvements based on customer feedback

ISO 14001 Requirements

- Identification of environmental impacts and legal obligations

- Implementation of an environmental management plan

- Monitoring and reporting on sustainability goals

ISO 50001 Requirements

- Establishing an energy management system

- Identifying opportunities for energy efficiency improvements

- Periodic reviews to achieve ongoing energy savings

ISO 45001 Requirements

- Hazard identification and risk assessment procedures

- Development of a safety management system

- Training programs for employees on health and safety protocols

ISO 22000 Requirements

- Hazard Analysis and Critical Control Points (HACCP) implementation

- Traceability systems to monitor the production process

- Compliance with food safety laws and standards

Contact us at [email protected] or call +91-8595603096 to learn more about how we can assist you!

Benefits of ISO Certifications for Glass and Glass Product Manufacturing

ISO certifications provide numerous benefits to manufacturers in the glass industry:

Product Quality: Adhering to ISO 9001 and other quality standards ensures consistent production processes, leading to improved product durability, safety, and customer satisfaction.

Marketing Advantage: With ISO certifications, businesses gain credibility in domestic and international markets. It serves as proof of their commitment to quality and sustainability.

Operational Efficiency: ISO 50001 and ISO 14001 focus on optimizing resource utilization, reducing waste, and lowering energy costs, which directly impacts profitability.

Regulatory Compliance: Compliance with ISO standards ensures adherence to legal and regulatory requirements, reducing the risk of penalties and reputational damage.

Worker Safety and Morale: ISO 45001 creates a safer working environment, boosting employee morale and reducing workplace

Environmental Sustainability: Through ISO 14001, glass manufacturers can adopt eco-friendly practices, align with global sustainability goals, and attract environmentally conscious customers.

The glass manufacturing industry is witnessing rapid growth, fueled by increasing demand for energy-efficient building materials, sustainable packaging solutions, and lightweight automotive components. Market research indicates that manufacturers investing in ISO certifications are better positioned to capitalize on these trends by offering high-quality, sustainable products.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Glass and Glass Product Manufacturing business, please contact us at [email protected] or +91-8595603096.

FAQs: ISO Certifications for Glass and Glass Product Manufacturing

What is the importance of ISO certifications for glass manufacturing?

ISO certifications help ensure product quality, improve operational efficiency, and demonstrate compliance with global standards, giving businesses a competitive advantage.

How long does it take to achieve ISO certification?

The timeline varies depending on the size of the organization, the complexity of its processes, and the specific standard being implemented. Typically, it ranges from a few weeks to several months.

Can small glass manufacturers benefit from ISO certifications?

Yes, ISO certifications are scalable and provide benefits such as enhanced quality, operational efficiency, and customer trust, regardless of the company size.

Are ISO certifications mandatory for glass manufacturers?

ISO certifications are not mandatory but are often required by clients, partners, or regulatory authorities to demonstrate adherence to industry best practices.

What costs are associated with ISO certification?

The costs depend on the organization’s size, the chosen standard, and the certification body. Pacific Certifications provides competitive and transparent pricing for all certification services.

How do ISO standards contribute to sustainability in the glass industry?

Standards like ISO 14001 and ISO 50001 encourage sustainable practices such as waste reduction, energy efficiency, and environmental management, making glass manufacturing eco-friendly.

Read More at: Blogs by Pacific Certifications