ISO Certifications for Explosives Manufacturing Businesses, Requirements and Benefits

Introduction

Explosives manufacturing is one of the most highly regulated and high-risk industries in the world. Used across mining, defense, construction, and aerospace sectors, the production, storage, and transport of explosives require exceptional control, safety, and traceability.

According to MarketsandMarkets(2024), the global industrial explosives market is projected to reach USD 17.8 billion by 2030, driven by mining expansion and defense modernization. To meet strict legal, environmental, and safety obligations, companies in this sector are increasingly turning to ISO certifications to systematize quality, safety, environmental management, and risk control.

In explosives manufacturing, one small error can have massive consequences — ISO certification ensures precision, safety, and accountability at every stage — Pacific Certifications

Looking to achieve ISO certification for your explosives manufacturing operations? Contact us at [email protected] to get started!

Quick Summary

ISO certifications such as ISO 9001, ISO 14001, ISO 45001, ISO 50001, and ISO 31000 help explosives manufacturers ensure safe production, regulatory compliance, and operational excellence. They build structured frameworks for process control, hazard prevention, and sustainability, ensuring both compliance and public trust.

Applicable ISO Standards for Explosives Manufacturing

Explosives manufacturers face unique operational and safety challenges. The following ISO standards are particularly relevant to ensuring the highest quality and safety standards in this specialized sector:

Standard | Description | Relevance |

|---|---|---|

ISO 9001 – Quality Management Systems (QMS) | Defines a process-based approach to maintaining product and service quality. | Ensures consistency in chemical formulation, mixing, and packaging of explosive materials. |

ISO 14001 – Environmental Management Systems (EMS) | Sets guidelines for controlling environmental impact and compliance. | Manages waste, emissions, and chemical effluents safely, minimizing environmental hazards. |

ISO 45001 – Occupational Health & Safety Management Systems (OHSMS) | Establishes a proactive framework for workplace safety. | Protects employees from explosions, fire hazards, and chemical exposure. |

ISO 50001 – Energy Management Systems (EnMS) | Optimizes energy efficiency and operational control. | Reduces energy costs in heating, drying, and chemical reaction processes. |

ISO/IEC 17025 – Testing & Calibration Laboratories | Ensures accuracy and reliability in laboratory testing. | Provides confidence in testing explosive strength, stability, and shelf life. |

ISO 31000 – Risk Management Guidelines | Offers structured principles for identifying and mitigating risks. | Strengthens risk assessment and control for raw material handling, mixing, and storage. |

ISO 22301 – Business Continuity Management Systems (BCMS) | Provides a framework for maintaining operations during disruptions. | Ensures critical processes continue during emergencies, accidents, or supply issues. |

ISO 26000 – Social Responsibility | Promotes ethical, responsible, and community-centered business practices. | Encourages transparent operations and community safety initiatives. |

ISO 9001:2015 – Quality Management Systems (QMS)

This is the global benchmark for quality management, emphasizing a customer-centric approach, risk management, and process improvement. In explosives manufacturing, a robust QMS ensures products meet customer and regulatory requirements while enhancing operational efficiency.

ISO 14001:2015 – Environmental Management Systems (EMS)

This standard is critical for explosives manufacturers who must manage their environmental impact. From the safe disposal of waste materials to pollution control, ISO 14001 helps manufacturers reduce environmental risks and improve sustainability.

ISO 45001:2018 – Occupational Health and Safety Management Systems (OHSMS)

Given the hazardous nature of explosives manufacturing, ISO 45001 plays an essential role in protecting workers’ health and safety. This standard helps organizations identify, mitigate, and manage health and safety risks.

ISO 50001:2018 – Energy Management Systems (EnMS)

Energy-intensive industries like explosives manufacturing benefit from ISO 50001, which focuses on energy efficiency and cost savings. The standard encourages better energy management practices, reducing operational costs and environmental impact.

ISO 27001:2022 – Information Security Management Systems (ISMS)

Explosives manufacturers handle sensitive information related to product formulation and customer data. ISO 27001 ensures the security of digital and physical information assets, minimizing data breaches and cyber threats.

ISO 45001:2018 – Occupational Health and Safety Management System

Prioritizing workplace safety is crucial for any explosives manufacturing company. ISO 45001 guides organizations in establishing a safe work environment, minimizing risks associated with explosive materials and equipment.

ISO 22301:2019 – Business Continuity Management Systems (BCMS)

Ensuring continuity in explosives manufacturing is essential given the critical nature of the product. ISO 22301 helps companies prepare for disruptions and recover efficiently, maintaining resilience against unforeseen incidents.

Click here to find out more applicable standards to your industry

What are the requirements of ISO Certifications for Explosives Manufacturing?

Below are the key requirements for explosives manufacturers seeking ISO certification:

General requirements:

Policy & Objectives: Define quality, safety, and environmental policies aligned with national explosive regulations.

Hazard Identification & Risk Assessment: Analyze risks associated with raw materials, processes, and storage.

Process Control Documentation: Establish standard procedures for mixing, filling, testing, and packaging.

Safety Protocols: Implement preventive and emergency controls for fire, explosion, and chemical exposure.

Training & Competence: Train all staff on explosive handling, emergency response, and quality control.

Testing & Verification: Maintain laboratory testing for chemical stability, detonation sensitivity, and packaging durability.

Supplier & Raw Material Control: Verify suppliers and raw materials to ensure chemical purity and compliance.

Internal Audits: Conduct regular audits to identify nonconformities and improvement opportunities.

Incident Reporting & Investigation: Record and analyze all near misses and accidents for preventive action.

Environmental Monitoring: Control and monitor air emissions, wastewater, and solid waste from production.

Legal & Regulatory Compliance: Ensure adherence to explosive manufacturing acts, environmental laws, and defense regulations.

Management Review: Conduct periodic reviews of quality, safety, and performance indicators.

Continuous Improvement: Use monitoring data to enhance safety, reduce waste, and improve efficiency.

Standard specific requirements:

ISO 9001:2015 – Quality Management Requirements

- Establish a Quality Management System based on a documented structure, policies, and procedures.

- Emphasize customer satisfaction, identifying areas for improvement and addressing complaints.

- Risk-based thinking, including hazard assessment and control measures for explosives.

ISO 14001:2015 – Environmental Management Requirements

- Develop a system to manage environmental aspects, including waste disposal, pollution prevention, and resource consumption.

- Implement sustainable practices and maintain legal compliance with environmental regulations.

- Document procedures for emergency preparedness and response to environmental incidents.

ISO 45001:2018 – Health and Safety Requirements

- Conduct regular risk assessments for handling and storing explosives.

- Implement controls to minimize workplace hazards, including PPE (personal protective equipment) and training.

- Develop emergency procedures for accidents, explosions, or other dangerous occurrences.

ISO 50001:2018 – Energy Management Requirements

- Create an energy management policy to improve efficiency in energy usage.

- Set energy performance indicators (EnPIs) to measure and monitor energy efficiency.

- Identify opportunities for energy-saving measures in production and operation.

ISO 27001:2022 – Information Security Requirements

- Define and enforce a policy for data security, ensuring confidentiality, integrity, and accessibility.

- Regularly assess risks related to information assets and establish controls to protect sensitive data.

- Train staff on cybersecurity practices, safeguarding information related to explosive materials.

Tip: Start with ISO 9001, 14001, and 45001 to build a strong foundation for safety and compliance, once established, integrate ISO 17025 and 31000 for testing precision and risk control.

If you're pursuing ISO certification for explosives manufacturing, contact us today at [email protected] for guidance.

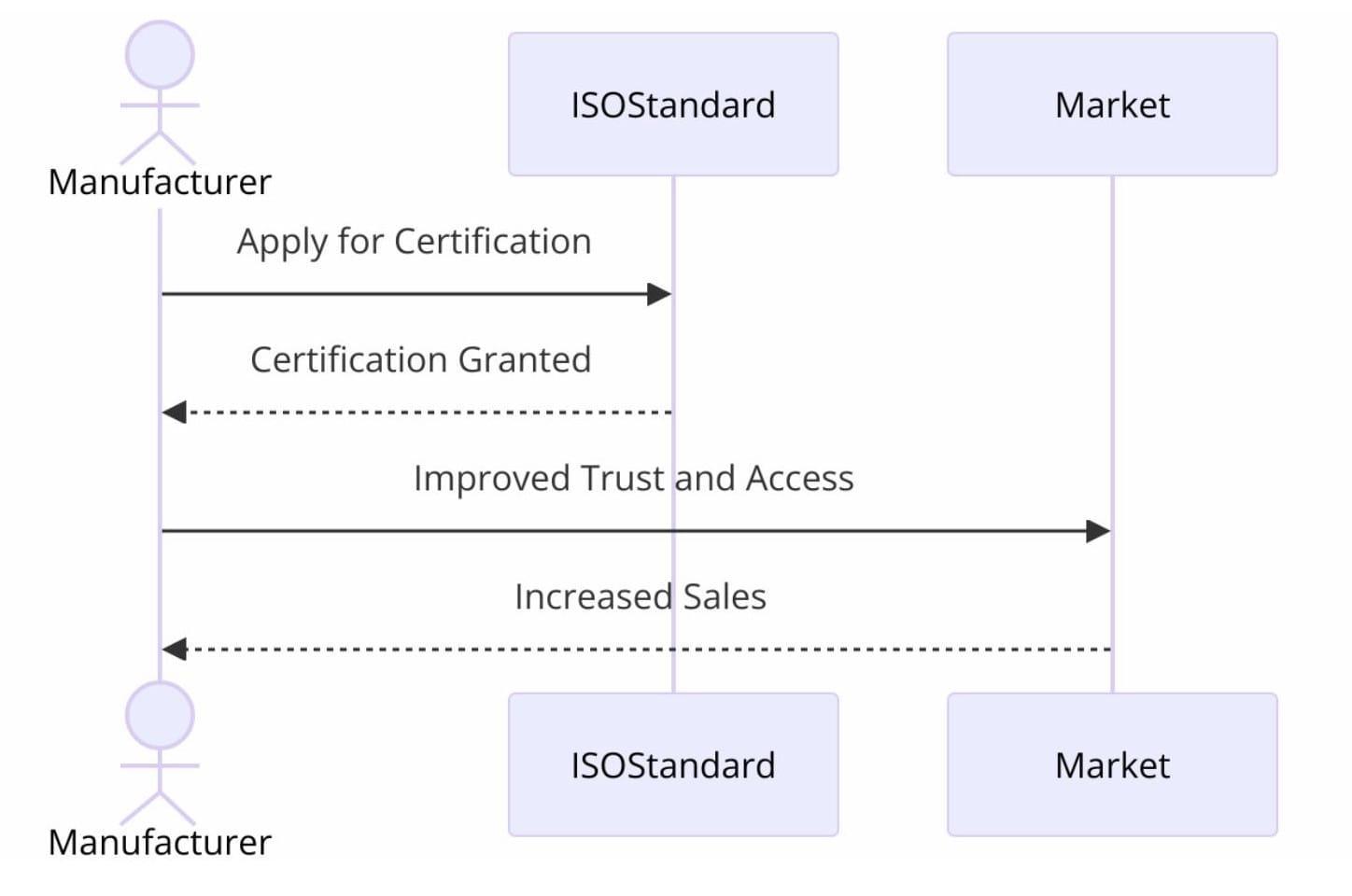

What are the benefits of ISO Certifications for Explosives Manufacturing businesses?

For explosives manufacturers, ISO certifications bring significant benefits that impact not only safety and compliance but also operational efficiency and reputation:

- Safety & Risk Control: ISO 45001 and ISO 31000 minimize the risk of explosions, fires, and chemical accidents.

- Quality Assurance: ISO 9001 ensures consistent performance and traceability across production batches.

- Compliance: Demonstrates adherence to strict defense, mining, and industrial explosive standards.

- Environmental Protection: ISO 14001 ensures responsible chemical disposal and pollution prevention.

- Efficiency: ISO 50001 reduces energy costs associated with high-temperature manufacturing.

- Operational Continuity: ISO 22301 ensures uninterrupted supply during crises or equipment breakdowns.

- Employee Safety: Builds a safety-oriented culture and reduces workplace incidents.

- International Recognition: Certification enhances credibility with defense contractors and global clients.

- Cost Reduction: Fewer incidents and improved efficiency lower operational and insurance costs.

According to ResearchAndMarkets, the industrial explosives market is expected to grow at a CAGR of 5.1% through 2030, led by the mining and defense sectors. Rising global focus on worker safety and sustainability has made certifications such as ISO 45001 and ISO 14001 critical for compliance.

ISO 9001-certified explosive plants report 30–40% fewer product defects, while ISO 17025-accredited labs achieve higher test accuracy and regulatory acceptance. Furthermore, government procurement and defense contracts increasingly require suppliers to be ISO-certified to ensure accountability and safety consistency.

By 2030, integrated ISO systems combining quality, environment, safety, and risk management are expected to be standard practice across the explosives industry, strengthening both global trade and local compliance.

How Pacific Certifications Can Help

Pacific Certifications is accredited by ABIS, we provide independent audit and certification services for explosives manufacturers, mining suppliers, and defense contractors. Our focus is on impartial, accredited certification recognized worldwide.

Pacific Certifications can help by:

- Conducting audits for ISO 9001, 14001, 45001, 50001, and 31000 etc.

- Issuing accredited ISO certificates accepted by global regulators and clients.

- Supporting integrated management system certification for manufacturing and testing units.

If you need support with ISO certification for your Explosives Manufacturing business, contact us at [email protected] or +91-8595603096.

FAQs: ISO Certifications for Explosives Manufacturing

1. Why is ISO certification important for explosives manufacturing?

ISO certification ensures that explosives manufacturers adhere to globally recognized standards for quality, safety, environmental management, and operational resilience.

2. Which ISO standards are most relevant to explosives manufacturing?

Standards such as ISO 9001, ISO 14001, ISO 45001, ISO 50001, ISO 27001, and ISO 22301 are highly applicable, covering areas from quality and safety to environmental impact and business continuity.

3. How long does it take to achieve ISO certification for explosives manufacturing?

The timeline varies based on the specific standard and the current compliance level of the organization. Generally, certification can take several months, including preparation, audits, and assessments.

4. Can ISO certification improve safety in explosives manufacturing?

Absolutely. ISO standards like ISO 45001 help establish safe practices, identify potential hazards, and create a safer working environment, reducing the risk of accidents in explosive manufacturing operations.

5. Does ISO certification require ongoing audits?

Yes, once certified, regular audits are necessary to maintain compliance and address any changes in the organization or industry requirements.

6. What is the role of Pacific Certifications in ISO certification for explosives manufacturing?

We conduct impartial audits and assess companies for compliance with ISO standards. Once compliance is confirmed, we issue the relevant certifications, demonstrating the organization’s adherence to international best practices.

7. How does ISO 27001 benefit explosives manufacturers?

ISO 27001 focuses on data security, protecting sensitive information related to explosives formulation, manufacturing processes, and customer details from breaches and cyber threats.

8. What are the environmental benefits of ISO 14001 for explosives manufacturers?

ISO 14001 helps companies manage and reduce their environmental impact by encouraging sustainable practices, waste reduction, and compliance with environmental laws.

9. How can ISO 50001 certification save costs for explosives manufacturers?

ISO 50001 focuses on energy efficiency, enabling companies to optimize energy use, lower operational costs, and reduce their environmental footprint.

Author: Ashish

Read More at: Blogs by Pacific Certifications