ISO Certifications for Concrete Manufacturing Businesses, Requirements and Benefits

Introduction to ISO Standards for Concrete Manufacturing

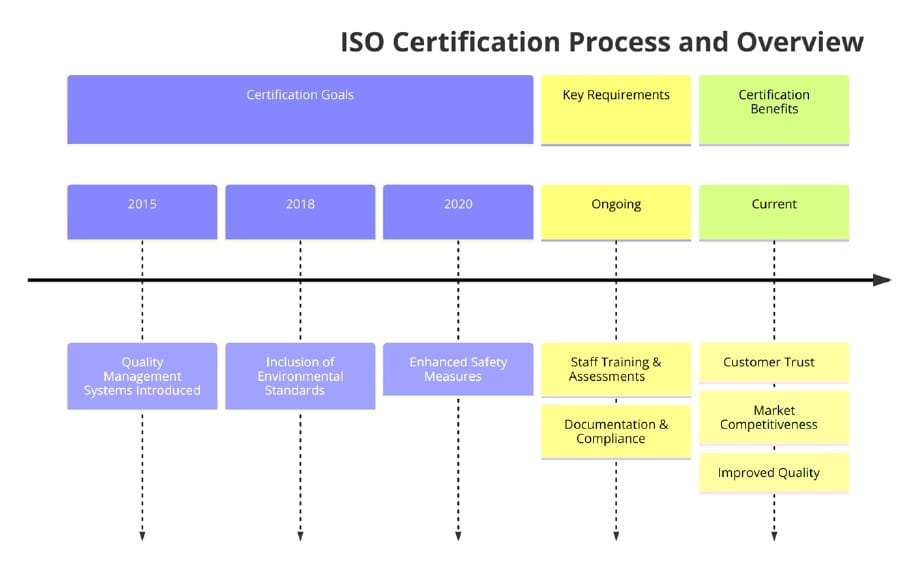

ISO certifications play a critical role in ensuring the quality, safety, and sustainability of concrete manufacturing processes. These standards provide a globally recognized framework to enhance operational efficiency, ensure compliance with regulatory norms, and foster customer confidence.

Concrete manufacturing, a key industry in infrastructure development, relies heavily on consistency and adherence to stringent standards, making ISO certifications indispensable.

ISO standards are globally recognized guidelines established by the International Organization for Standardization (ISO). These standards ensure that products, services, and processes are safe, reliable, and of high quality.

For the concrete manufacturing industry, ISO standards are especially vital because they provide a structured framework for maintaining product consistency and improving operational practices.

Concrete manufacturing is a complex process involving raw material selection, production methodologies, quality control, and environmental impact management. ISO certifications help manufacturers streamline these processes and reduce potential risks, enhancing their credibility in the competitive market.

Looking for reliable ISO certification? Contact us at [email protected] or call us at +91-8595603096 to begin your journey toward global compliance.

Applicable ISO Standards for Concrete Manufacturing

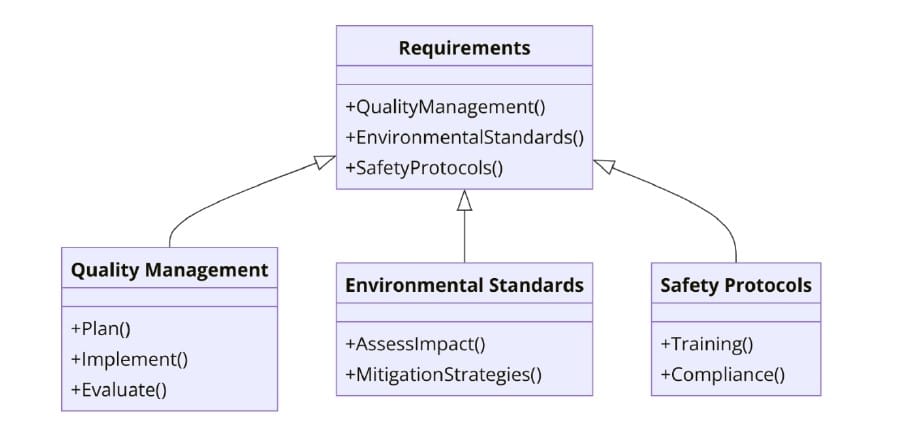

Concrete manufacturing touches upon multiple aspects of production, from quality management to environmental sustainability. Below are the primary ISO standards applicable to the industry:

ISO 9001: Quality Management System

ISO 9001 establishes guidelines for a quality management system, ensuring that concrete manufacturers consistently deliver products that meet customer expectations and regulatory requirements.

ISO 14001: Environmental Management System

This standard emphasizes environmental performance, helping manufacturers minimize their ecological footprint. ISO 14001 is essential for sustainable concrete production practices, such as waste management and resource efficiency.

ISO 45001: Occupational Health and Safety Management System

Concrete manufacturing involves potentially hazardous operations. ISO 45001 provides a framework to manage workplace health and safety effectively, protecting workers from accidents and injuries.

ISO 50001: Energy Management System

Energy efficiency is critical in concrete manufacturing due to the energy-intensive nature of the production processes. ISO 50001 guides organizations in optimizing energy consumption, reducing costs, and promoting sustainable practices.

ISO 26000: Guidance on Social Responsibility

Although not certifiable, ISO 26000 is relevant for manufacturers seeking to align their operations with social responsibility principles, ensuring ethical practices throughout the supply chain.

ISO 22301: Business Continuity Management

This standard helps manufacturers ensure the continuity of operations during disruptions, such as supply chain issues or natural disasters, critical in maintaining product delivery timelines.

ISO 17025: Testing and Calibration Laboratories

Concrete manufacturers often rely on laboratory testing for quality control. ISO 17025 certification ensures the accuracy and reliability of these laboratory services.

Click here to find out more applicable standards to your industry

How we can help?

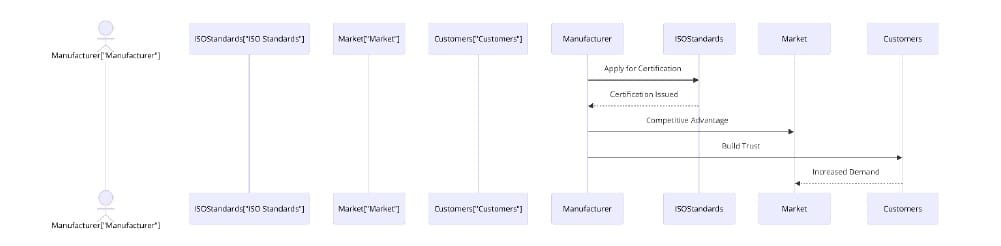

At Pacific Certifications, we specialize in auditing and certifying organizations against applicable ISO standards. Our team of experienced auditors ensures a seamless certification process by thoroughly evaluating your compliance with the relevant standards.

With years of expertise in the field, Pacific Certifications has established itself as a trusted partner for organizations aiming to achieve ISO certifications.

We provide end-to-end support for the certification journey, delivering objective and credible audits. As an impartial certification body, we take pride in fostering transparency and excellence in concrete manufacturing.

If you’re seeking ISO certification for your concrete manufacturing business, connect with us at [email protected] or call +91-8595603096.

Requirements of ISO Certifications for Concrete Manufacturing

Each ISO standard comes with specific requirements tailored to different aspects of concrete manufacturing. Below is a summary of the key requirements:

ISO 9001: Quality Management System requirements:

- Establishing a quality policy and objectives

- Documented processes for quality assurance

- Regular internal audits and management reviews

- Consistent monitoring of customer satisfaction

ISO 14001: Environmental Management System requirements:

- Identification of environmental aspects and impacts

- Implementation of controls to minimize environmental risks

- Compliance with applicable legal requirements

- Continuous improvement through environmental management programs

ISO 45001: Occupational Health and Safety Management System requirements:

- Risk assessments for workplace safety

- Implementing preventive and protective measures

- Training and awareness for workers

- Emergency preparedness and response planning

ISO 50001: Energy Management System requirements:

- Conducting energy audits

- Establishing energy performance indicators (EnPIs)

- Developing energy-saving objectives and action plans

- Continuous monitoring and improvement of energy usage

ISO 22301: Business Continuity Management requirements:

- Risk assessments for potential disruptions

- Development of a business continuity plan

- Regular testing and maintenance of continuity strategies

- Communication protocols during disruptions

For ISO certification tailored to concrete manufacturing, email us at [email protected] or give us a call at +91-8595603096.

Benefits of ISO Certifications for Concrete Manufacturing

The implementation of ISO standards brings a multitude of benefits, transforming concrete manufacturing processes and enhancing business outcomes:

Improved Product Quality: ISO standards ensure consistency and high quality in concrete products, boosting customer trust and satisfaction.

Enhanced Operational Efficiency: By streamlining processes, ISO certifications help minimize waste, reduce errors, and optimize resource utilization.

Regulatory Compliance: Adhering to ISO standards helps manufacturers comply with local and international regulations, avoiding legal complications.

Sustainability and Environmental Responsibility: ISO 14001 and ISO 50001 certifications enable organizations to adopt eco-friendly practices, reducing their environmental footprint.

Workplace Safety: With ISO 45001, concrete manufacturers can foster a safer work environment, reducing the risk of accidents and improving employee morale.

Market Competitiveness: ISO certifications enhance brand credibility, providing a competitive edge in the global market.

Business Continuity: ISO 22301 ensures that operations continue uninterrupted during crises, safeguarding revenue and customer trust.

Ready to elevate your concrete manufacturing with ISO certification? Contact [email protected] or call us at +91-8595603096.

Market Trends

In 2025, the concrete manufacturing industry is increasingly aligning with sustainability and digital transformation trends. Innovations such as green concrete, automation in production, and AI-driven quality control are reshaping the sector. Moreover, stricter regulatory frameworks emphasize the adoption of ISO standards to meet environmental and safety requirements.

Industry reports indicate a surge in demand for sustainable practices, with ISO-certified manufacturers gaining significant market preference. The integration of energy-efficient technologies and the shift toward net-zero carbon emissions have positioned ISO 50001 as a crucial certification.

Are you ready to elevate your concrete manufacturing processes with ISO certifications? At Pacific Certifications, we ensure a smooth and transparent certification journey tailored to your needs. Embrace the benefits of globally recognized standards and transform your operations today!

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Concrete Manufacturing business, please contact us at [email protected] or +91-8595603096.

FAQs: ISO Certifications for Concrete Manufacturing

What is the importance of ISO certifications for concrete manufacturing?

ISO certifications ensure consistent quality, safety, and environmental sustainability in concrete manufacturing processes, enhancing operational efficiency and market credibility.

Which ISO standards are most relevant for concrete manufacturing?

Key standards include ISO 9001 for quality, ISO 14001 for environmental management, ISO 45001 for workplace safety, ISO 50001 for energy efficiency, and ISO 22301 for business continuity.

How does ISO 50001 benefit concrete manufacturers?

ISO 50001 helps manufacturers optimize energy consumption, reduce operational costs, and promote sustainability, aligning with modern industry trends.

Can Pacific Certifications help with ISO training and implementation?

No, Pacific Certifications specializes in auditing and certifying organizations against ISO standards but does not provide training or implementation services.

What are the steps to achieve ISO certification?

The process involves understanding applicable standards, implementing required practices, undergoing audits, and obtaining certification from a trusted body like Pacific Certifications.

How can I contact Pacific Certifications?

You can reach us at [email protected] for inquiries and assistance with ISO certifications.

Read More at: Blogs by Pacific Certifications