ISO Certifications for Chips Manufacturing Businesses, Requirements and Benefits

ISO Standards for Chips Manufacturing

ISO certifications play a pivotal role in ensuring quality and environmental sustainability in chips manufacturing. Whether producing semiconductor chips or snack food chips, implementing ISO standards helps businesses improve customer satisfaction and maintain operational excellence.

The chips manufacturing sector, encompassing both semiconductor chips and food chips, is a cornerstone of modern industries. While semiconductor chips power the digital world, food chips are an integral part of the global snack industry. For these diverse sectors, International Organization for Standardization (ISO) standards provide frameworks that ensure quality, safety, and efficiency.

In 2024, as the global market for chips manufacturing becomes increasingly competitive, ISO certifications remain indispensable for maintaining credibility and meeting consumer expectations. Certification to relevant ISO standards signals a commitment to excellence, providing a structured approach to managing processes and achieving consistent outcomes.

If you’re looking for ISO certification for chips manufacturing, reach out to us at [email protected] or call us at +91-8595603096. Our team is ready to assist you.

Applicable ISO Standards for Chips Manufacturing

Understanding the applicable ISO standards for chips manufacturing is crucial for maintaining compliance and operational efficiency. The following standards are particularly relevant:

ISO 9001: Quality Management System (QMS)

This standard is foundational for chips manufacturers aiming to ensure consistent quality in their products. It focuses on process optimization, risk management, and continual improvement.

ISO 14001: Environmental Management System (EMS)

For chips manufacturers, addressing environmental impact is essential. ISO 14001 guides organizations in reducing waste, managing resources efficiently, and demonstrating environmental responsibility.

ISO 45001: Occupational Health and Safety (OHS)

Worker safety is a priority in manufacturing. ISO 45001 helps chips manufacturers create a safer working environment by identifying risks and implementing controls.

ISO 22000: Food Safety Management System

For snack food chips manufacturers, ISO 22000 ensures the safety of food products throughout the supply chain. It integrates the principles of Hazard Analysis and Critical Control Points (HACCP).

ISO 22301: Business Continuity Management System

ISO 22301 supports chips manufacturers in preparing for disruptions, ensuring uninterrupted production and supply chain operations.

ISO 27001: Information Security Management System

Semiconductor chips manufacturers often handle sensitive data. ISO 27001 protects this data by providing a framework for managing information security risks.

ISO 50001: Energy Management System

Energy efficiency is critical for cost management in chips manufacturing. ISO 50001 helps organizations optimize energy use, reducing operational costs and environmental impact.

At Pacific Certifications, we specialize in providing reliable and efficient ISO certification services for chips manufacturers. As a trusted certification body, we conduct comprehensive audits and issue ISO certifications that verify your compliance with the relevant standards.

Our process is transparent and customer-focused, ensuring a smooth certification journey from initial audit to certification issuance. With extensive experience in manufacturing industries, our auditors bring a deep understanding of sector-specific challenges, ensuring that your certification aligns with best practices.

Need ISO certification for your chips manufacturing business? Get in touch with us at [email protected] or give us a call at +91-8595603096 today.

Requirements of ISO Certifications for Chips Manufacturing

Below are the key requirements of each relevant ISO standard for chips manufacturing. Each standard has specific criteria tailored to different aspects of production, management, and compliance:

ISO 9001: Quality Management System (QMS)

- Establishing a Quality Policy: Develop a documented quality policy aligned with organizational objectives.

- Process Documentation: Define and document processes critical to ensuring product quality.

- Customer Focus: Understand and meet customer requirements to enhance satisfaction.

- Risk-Based Thinking: Identify risks and opportunities to ensure consistent quality outcomes.

- Performance Monitoring: Use key performance indicators (KPIs) to measure and improve processes.

- Internal Audits: Conduct regular audits to ensure the QMS is effective and compliant.

ISO 14001: Environmental Management System (EMS)

- Environmental Policy: Establish an environmental policy that reflects commitment to sustainability.

- Impact Assessment: Identify environmental aspects and assess their impact.

- Legal Compliance: Ensure compliance with all relevant environmental laws and regulations.

- Objectives and Targets: Set measurable environmental goals and implement action plans.

- Continual Improvement: Monitor performance and take corrective actions to improve.

ISO 45001: Occupational Health and Safety (OHS)

- Health & Safety Policy: Develop policies to prevent workplace injuries and illnesses.

- Risk Assessments: Identify workplace hazards and assess associated risks.

- Worker Participation: Involve employees in safety initiatives and decision-making processes.

- Training Programs: Provide safety training to employees to ensure compliance and awareness.

- Incident Reporting: Establish systems to report, investigate, and address safety incidents.

ISO 22000: Food Safety Management System (FSMS) (For Snack Food Chips)

- Food Safety Policy: Define a policy that outlines your approach to managing food safety risks.

- HACCP Principles: Apply Hazard Analysis and Critical Control Points (HACCP) for risk management.

- PRPs (Prerequisite Programs): Implement programs to maintain hygienic conditions in production.

- Traceability: Establish systems to trace ingredients and finished products.

- Supply Chain Communication: Ensure food safety information flows effectively across the supply chain.

ISO 27001: Information Security Management System (ISMS) (For Semiconductor Chips)

- Information Security Policy: Develop a policy for managing and safeguarding sensitive information.

- Asset Management: Identify and manage information assets.

- Access Control: Limit access to critical systems and data only to authorized personnel.

- Risk Assessment: Identify and evaluate risks to information security.

- Incident Management: Implement procedures to handle and report security breaches.

ISO 50001: Energy Management System (EnMS)

- Energy Policy: Create a policy outlining your commitment to improving energy performance.

- Energy Review: Conduct an energy review to identify areas for efficiency improvement.

- Energy Objectives: Set measurable targets and action plans for energy optimization.

- Operational Control: Monitor and control energy usage in critical operations.

- Continual Improvement: Regularly evaluate performance and update energy management strategies.

These standards collectively address quality, safety, environmental impact, energy efficiency, and information security, ensuring comprehensive compliance and excellence in chips manufacturing.

For reliable ISO certification services for chips manufacturing, email us at [email protected] or call +91-8595603096 to start your certification journey.

Benefits of ISO Certifications for Chips Manufacturing

Enhanced Product Quality and Safety: ISO certifications establish robust systems for ensuring consistent product quality, reducing defects, and enhancing customer satisfaction.

Compliance: Compliance with ISO standards ensures chips manufacturers meet legal and industry-specific regulations, minimizing risks of fines and recalls.

Market Competitiveness: ISO-certified companies gain a competitive edge by showcasing their commitment to quality and reliability. Customers often prefer certified suppliers, particularly in highly regulated markets.

Efficiency: ISO standards promote streamlined processes, better resource utilization, and reduced waste, resulting in cost savings and higher profitability.

Sustainability and Environmental Responsibility: ISO 14001 and ISO 50001 help chips manufacturers minimize their carbon footprint, aligning with global sustainability goals and enhancing brand reputation.

The chips manufacturing industry is witnessing rapid technological advancements and heightened consumer expectations. Semiconductor chips are driving innovations in AI, 5G, and electric vehicles, while snack food chips are seeing a demand for healthier, sustainable products.

Adopting ISO certifications allows manufacturers to stay ahead in this dynamic landscape, addressing quality, sustainability, and safety concerns effectively.

Ready to elevate your chips manufacturing business with ISO certifications? At Pacific Certifications, we are here to help you achieve compliance and unlock new growth opportunities.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Chips Manufacturing business, please contact us at [email protected] or +91-8595603096.

FAQs: ISO Certifications for Chips Manufacturing

What is the importance of ISO certifications in chips manufacturing?

ISO certifications provide a structured framework for ensuring quality, safety, and efficiency in chips manufacturing. They help companies meet regulatory requirements and enhance customer trust.

Which ISO standards are applicable to semiconductor chips manufacturing?

ISO 9001, ISO 14001, ISO 45001, ISO 27001, and ISO 50001 are highly relevant for semiconductor chips manufacturers.

How can Pacific Certifications help chips manufacturers?

Pacific Certifications conducts audits and issues ISO certifications, verifying compliance with relevant standards to ensure your business meets industry expectations.

What are the benefits of ISO 22000 for snack food chips manufacturers?

ISO 22000 ensures food safety throughout the supply chain, reduces risks of contamination, and enhances customer confidence in your products.

Is ISO 50001 mandatory for chips manufacturers?

While not mandatory, ISO 50001 is beneficial for chips manufacturers looking to optimize energy use and reduce operational costs.

How long does it take to get ISO certified?

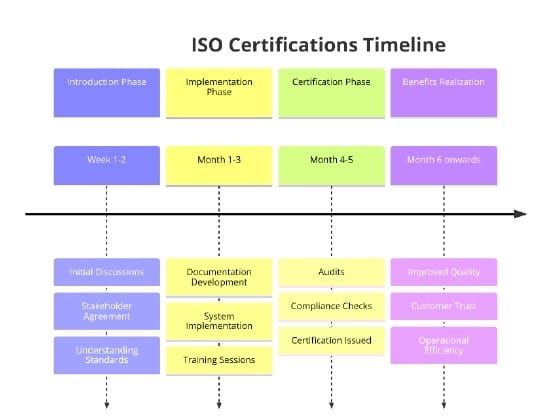

The timeline varies based on factors like company size, processes, and preparedness, but the certification process typically spans a few weeks to months.

Read More at: Blogs by Pacific Certifications