ISO Certification in Construction Projects: Managing Safety, Quality & Risk

Construction projects bring together many moving parts - owners, designers, contractors, suppliers and regulators under tight timelines and public scrutiny. Institutions must control site safety, material quality, schedules and costs while meeting environmental and community expectations. ISO certifications give construction teams a shared playbook for planning, execution and handover, so they can control risks, keep people safe and deliver predictable outcomes.

Start your ISO certification journey with Pacific Certifications and strengthen safety, quality and risk management in your projects!

Quick summary

ISO certifications help construction institutions manage safety, quality, environment, information security and continuity across projects of all sizes. The most used are ISO 9001 for quality, ISO 14001 for environment, ISO 45001 for health and safety, ISO 19650 for BIM information management, ISO/IEC 27001 for security of project data and ISO 22301 for continuity. Certification supports tender eligibility, supplier approval and measurable results through KPIs such as incident rate, right first-time quality, rework cost, audit closure time and SLA performance for critical subcontractors.

Introduction

Every construction project balances safety, quality, schedule and cost. Errors can injure people, cause delays and lead to disputes. ISO standards give a tested way to define scope, assess risk, build controls into day-to-day work and keep evidence that decisions were made responsibly. When owners and general contractors align on ISO requirements, they speed up prequalification, improve coordination and reduce claims at handover.

Why ISO certifications matter in construction?

Clients and regulators expect proof that risks are controlled throughout design and construction. Certification provides independent confirmation that policies exist, roles are clear and controls operate on site and in the supply chain. It also shortens due diligence for bids and partner onboarding because buyers recognize the standards. For multi-site programs, one ISO system creates a consistent way of working across projects, regions and subcontractors.

ISO standards in construction — quick reference table

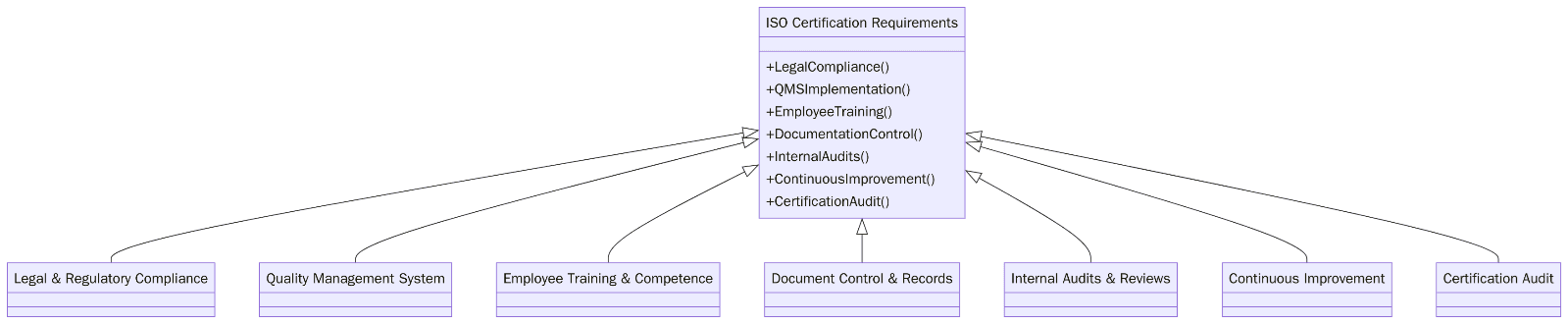

What are the requirements for ISO certification in construction?

Before institutions can achieve certification, they must ensure that their management systems are structured and supported with evidence that meets global expectations. These requirements cover policies, risk assessments, training, records, and leadership review. They help construction institutions manage safety, quality and risk consistently across projects. Below are the key requirements:

Define scope for the project, program, or entire portfolio with organizational boundaries

Publish policies for quality, safety, environment, data security and continuity with named owners

Conduct risk assessments for design risks, site hazards, supply constraints and information risks

Document processes for design reviews, procurement, site controls, inspections and handover

Provide evidence records such as permits to work, ITPs, daily logs, calibration and equipment checks

Train staff and subcontractors on roles, method statements and emergency response

Implement operational controls for high-risk activities, change control and temporary works

Carry out internal audits at project and corporate levels with actions tracked to closure

Leadership reviews of KPIs, incidents and supply performance

Correct non-conformities with root cause analysis and verification of closure

Commit to continual improvement through lessons learned and design standard updates

How to prepare for ISO certification in construction?

Preparation involves mapping current practices against ISO standards and filling the gaps with training, records, and stronger controls. Institutions that prepare thoroughly are more likely to achieve certification quickly and with fewer non-conformities.

Run a gap analysis against target standards across design offices and sites

Align policies and procedures so project teams and subcontractors use the same forms and workflows

Train crews and supervisors on permits, risk controls and evidence recording

Set up documentation in a common data environment for drawings, RFIs, inspections and approvals

Implement risk controls for lifting, work at height, confined spaces and energy isolation

Pilot internal audits on an active project, then fix findings before the external audit

Define KPIs and SLAs such as defect closure time, safety observation response time, supplier delivery SLA and audit closure time

Certification audit

The certification audit is a structured process that evaluates both documentation and site implementation. It is carried out in two stages, followed by surveillance and recertification audits to confirm ongoing compliance.

Stage 1 audit: Reviews scope, policies, risk assessments and project records for readiness.

Stage 2 audit: Evaluates implementation on live sites and design offices through sampling and interviews.

Non-conformities: Must be corrected with documented proof before approval.

Management review: Confirms leadership oversight and follow through on actions.

Final certification: Awarded once all gaps are resolved.

Surveillance audits: Conducted annually to verify ongoing effectiveness.

Recertification audits: Required every three years to maintain certification.

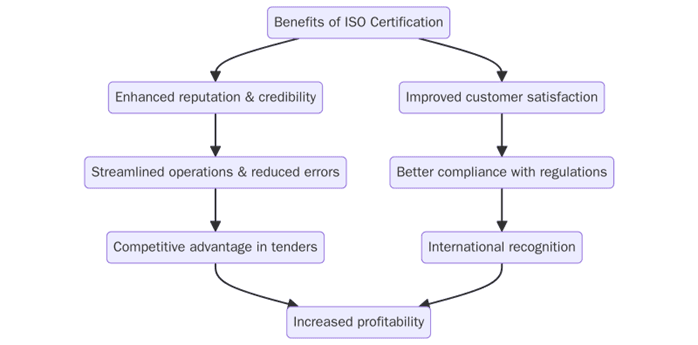

What are the benefits of ISO certification in construction?

The benefits of ISO certification extend beyond compliance, providing safer sites, stronger governance, and measurable results. Organizations that adopt ISO standards can track performance with KPIs and SLAs to reduce rework, improve tender success and gain market trust. Below are some of the key benefits:

Safer sites through clear permits, supervision and method statements

Better quality with planned inspections, hold points and defect control

Fewer delays due to faster approvals and coordinated design reviews

Lower rework by using BIM and standard details with change control

Stronger supply chain control through prequalification and SLA tracking

Easier handover with complete records and defect closure discipline

Greater tender success where ISO is listed as a requirement

Owners are writing ISO clauses into contracts, asking for ISO 9001, ISO 45001, ISO 14001 and ISO 19650 alignment on all major projects. Common data environments link quality and safety records to drawings, so punch lists and permits live with the model. Many companies add ISO/IEC 27001 due to growing threats to project information and ISO 22301 to manage supply shocks and site shutdowns. Dashboards track incident rate, approval turnaround, defect closure time, audit closure time and supplier SLA performance, showing that certification supports real outcomes, not just paperwork.

Contact us

Pacific Certifications provides accredited ISO certification services for construction companies and project owners. Our audits help you align design, site controls and supply management with clear evidence and measurable results.

Request your ISO audit plan and fee estimate, we will help you map Stage 1 and Stage 2 timelines and evidence requirements for your organization. Contact us at [email protected] or visit www.pacificcert.com.

If you need support with ISO certification in Construction Projects, contact us at [email protected].

Author: Alina Ansari

Read More at: Blogs by Pacific Certifications