ISO 9001, ISO 14001 and ISO 45001: Key Differences Explained

Introduction

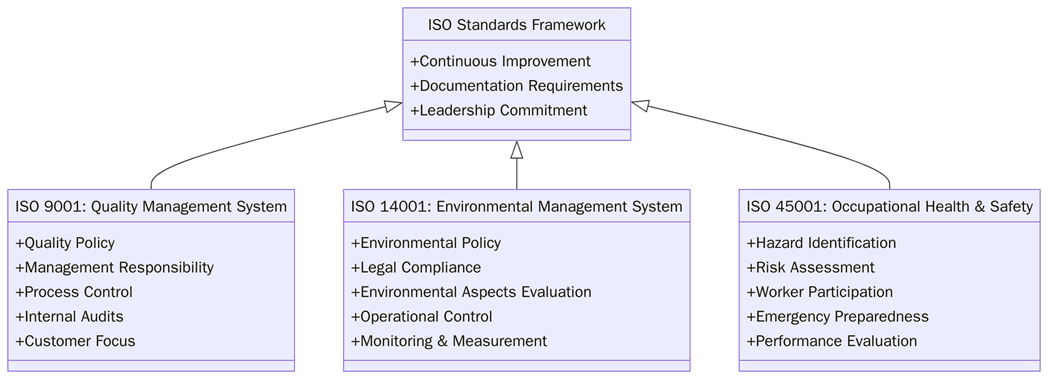

In today’s global business landscape, organizations are expected to not only deliver quality products and services but also operate responsibly and ensure employee safety. Three of the most recognized ISO standards-ISO 9001 (Quality Management), ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health & Safety Management), together form the foundation of modern integrated management systems.

These standards share a unified structure under Annex SL, enabling seamless integration within a single organizational framework. When applied collectively, they help businesses improve quality consistency, reduce environmental impact and minimize workplace risks, driving operational efficiency and sustainability.

Discuss your integrated certification plan with Pacific Certifications - schedule a 15-minute session to align your quality, environment and safety goals.

Quick summary

ISO 9001, ISO 14001 and ISO 45001 work together to strengthen an organization’s overall management framework. ISO 9001 focuses on quality and customer satisfaction, ISO 14001 addresses environmental performance and sustainability, while ISO 45001 ensures occupational health and safety. Combined, they deliver a balanced approach to excellence - protecting customers, employees and the planet simultaneously.

Why integrating ISO 9001, ISO 14001 and ISO 45001 matters?

Organizations no longer operate in isolation from social and environmental expectations. Customers demand consistent quality, regulators require environmental responsibility and employees expect safe workplaces. Implementing these three standards allows institutions to address all these expectations under one system.

Integrated certification streamlines internal audits, document control and risk assessments. It also enhances brand credibility and reduces the administrative burden of maintaining multiple stand-alone systems. The result is a lean, transparent and accountable organization that balances profitability with sustainability and safety.

“When ISO 9001, ISO 14001 and ISO 45001 work together, organizations move from isolated compliance to integrated performance, achieving operational excellence, sustainability and workforce safety within a single management culture.”

ISO 9001 vs ISO 14001 vs ISO 45001- key comparison

Aspect | ISO 9001 | ISO 14001 | ISO 45001 |

Focus | Quality management and customer satisfaction | Environmental management and sustainability | Occupational health & safety management |

Objective | Deliver consistent quality and continual improvement | Reduce environmental impact and meet compliance | Prevent work-related injuries and illnesses |

Core principle | Process approach and customer focus | Life-cycle perspective and pollution prevention | Risk elimination and worker participation |

Risk approach | Process-based risk management | Environmental aspect and impact evaluation | Hazard identification and risk control |

Legal emphasis | Product, service and customer requirements | Environmental laws, emissions and waste management | Health and safety regulations |

Key processes | Nonconformity control, corrective actions, customer feedback | Environmental policy, compliance evaluation, emergency response | Hazard control, emergency preparedness, incident investigation |

Primary metrics | Defect rate, customer satisfaction, audit closure time | Waste reduction, energy use, emission control, compliance status | Lost time injury frequency rate (LTIFR), near-miss ratio, training completion |

Common structure | PDCA model with continuous improvement | PDCA model aligned with sustainability goals | PDCA model focusing on safety and prevention |

What are the requirements for ISO 9001, ISO 14001 and ISO 45001?

Implementing these standards together requires structured planning and clear documentation. The goal is to build one integrated management system that addresses quality, environmental and occupational safety aspects simultaneously. Below are the key requirements:

- Define the scope and context of the organization, including internal and external factors affecting quality, environment and safety.

- Establish leadership commitment, top management must define policies, assign roles and provide resources for each area.

- Identify risks and opportunities related to customer satisfaction, environmental impact and worker health.

- Develop integrated policies and objectives for quality, environment and safety.

- Maintain documented procedures for control of processes, emissions, waste handling and emergency response.

- Conduct training and competence programs to ensure employee awareness of quality and safety responsibilities.

- Carry out internal audits and management reviews covering all three standards to track performance and ensure continual improvement.

- Engage in communication and consultation with stakeholders, including employees, suppliers and local authorities.

- Implement corrective and preventive actions for nonconformities identified during internal or external audits.

- Prepare for Stage 1 and Stage 2 certification audits under an accredited body like Pacific Certifications.

Tip:Build one risk register that includes process risks (ISO 9001), environmental aspects (ISO 14001) and safety hazards (ISO 45001). This integrated approach minimizes duplication and ensures a unified review process.

How to prepare for certification?

Integrating these systems requires coordination between departments and leadership support. Start by analyzing current processes and identifying overlaps.

- Perform a gap analysis against each standard’s requirements.

- Align policies and procedures to ensure consistency across all management areas.

- Conduct employee workshops on integrated risk management.

- Develop shared documentation — one manual, one audit program and one management review.

- Verify legal compliance for environmental and safety obligations.

- Review key performance indicators (KPIs) for quality, environment and safety together.

- Schedule internal audits that assess all three systems in one cycle before external certification.

Certification audit

Stage 1 audit: Review of documentation, scope and readiness for integrated management systems.

Stage 2 audit: On-site assessment of implementation and effectiveness across quality, environmental and safety processes.

Nonconformities: Identified issues must be corrected with evidence before certification approval.

Management review: Confirms leadership involvement and alignment with strategic direction.

Final certification: Granted after successful closure of findings.

Surveillance audits: Conducted annually to ensure sustained compliance.

Recertification audits: Required every three years.

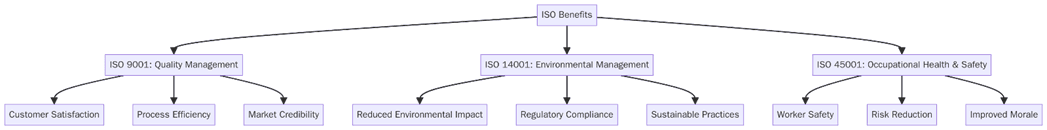

What are the benefits of integrated certification?

Organizations that combine ISO 9001, ISO 14001 and ISO 45001 gain measurable advantages that extend beyond compliance. Below are the key benefits:

- Unified management system that reduces duplication and administrative effort.

- Stronger organizational consistency across departments and processes.

- Improved compliance with quality, environmental and safety regulations.

- Cost savings from shared audits, documentation and training resources.

- Enhanced brand reputation through demonstrated commitment to quality, sustainability and safety.

- Reduced incidents, waste and rework through standardized risk controls.

- Measurable KPIs such as reduced defect rates, lower emissions and improved LTIFR.

- Improved employee morale and engagement through clear safety and quality objectives.

- Easier integration with ESG reporting and sustainability frameworks.

- Long-term business resilience through data-driven performance evaluation.

Integrated systems also improve communication and accountability between departments, leading to faster decision-making and stronger customer trust.

Market Trends

In recent years, industries are adopting integrated management systems to meet growing ESG expectations and supply chain transparency requirements. More organizations are linking ISO 9001, ISO 14001 and ISO 45001 with ISO 27001 (information security) and ISO 22301 (business continuity) to create enterprise-wide governance models. Digital audit platforms, KPI dashboards and AI-based risk analytics are also gaining traction to monitor performance in real time.

By 2030, the convergence of management systems will become standard practice. Organizations will rely on data-driven compliance monitoring and real-time reporting to maintain certification. Sustainability metrics and workforce well-being indicators will be integrated into annual audit programs. Certification to ISO 9001, ISO 14001 and ISO 45001 will become a baseline requirement for global supply chain participation, reinforcing trust, traceability and responsible operations.

Training and courses

Pacific Certifications provides accredited training programs for ISO 9001, ISO 14001 and ISO 45001 to help organizations build the knowledge needed to implement, audit and maintain integrated systems:

- Lead Auditor Training: Designed for professionals auditing quality, environmental and safety management systems together. The course covers audit planning, risk-based assessment, performance measurement and reporting across all three standards.

- Lead Implementer Training: For managers and coordinators developing or improving integrated management systems. The course focuses on documentation, risk management and alignment of objectives between quality, environmental and safety requirements.

Contact [email protected] to schedule ISO 9001, ISO 14001 and ISO 45001 training sessions and strengthen your organization’s integrated management capabilities.

How Pacific Certifications can help?

Pacific Certifications provides accredited certification services for ISO 9001, ISO 14001 and ISO 45001. Our audits help organizations build robust integrated systems that ensure quality, sustainability and safety. As an accredited certification body, we focus purely on impartial assessment and certification, not consultancy.

Request your ISO audit plan and fee estimate. We will help you map Stage-1/Stage-2 timelines and evidence requirements for your organization. Contact us at [email protected] or visit www.pacificcert.com.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Author: Alina Ansari

Suggested Certifications –

Read more: Pacific Blogs