ISO 59001 Circular Economy Management System Guide for Businesses

Introduction

Businesses are under pressure to move away from the “take–make–waste” model toward one where materials, components and products stay in use for longer and waste is treated as a design failure rather than an afterthought. Customer expectations, resource constraints, extended producer responsibility schemes and climate targets are all pushing companies to rethink how they design, source, manufacture, sell, maintain and recover products.

The emerging ISO 59001 standard is being developed as a circular economy management system standard, similar in structure to ISO 9001 (Quality Management), ISO 14001 (Environmental Management) but focused on circularity. It is intended to give organizations a requirements-based framework to embed circular thinking into policies, processes, metrics and governance so that resource loops are planned and managed rather than left to one-off projects.

If your business wants to build a structured approach to circular economy practices or prepare for future certification, you can request an ISO 59001-oriented audit plan from Pacific Certifications to review scope, timelines and the evidence you will need once the standard is finalized.

Quick summary

ISO 59001 is part of the ISO 59000 family on circular economy. While other standards in the series such as ISO 59004, ISO 59010 and ISO 59020 provide principles, business model guidance and measurement approaches, ISO 59001 is being designed as a certifiable management system standard. It will set requirements for establishing, operating and improving a circular economy management system that links strategy, design, procurement, operations, logistics and end-of-life treatment. For businesses, this means a single framework to plan circular initiatives, run them consistently and show evidence of performance over time.

Why ISO 59001 matters for businesses?

Most organizations today run circular economy initiatives in pockets: a recycling pilot in one plant, a repair program run by a service team, a refill concept in marketing, a material substitution project in R&D. Without a unifying management system, efforts stay fragmented; gains in one area can be cancelled out by decisions elsewhere. ISO 59001 aims to pull these activities into one system, anchored in policy, objectives and management review.

By using ISO 59001, companies can align product design, sourcing, production, logistics, sales and after-sales service around resource retention goals. It links high-level ambitions such as “reduce waste” or “increase recycled content” with day-to-day processes like specification of materials, supplier selection, reverse logistics planning and maintenance strategies.

What are the requirements for ISO 59001?

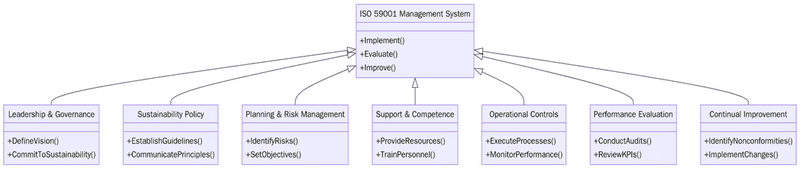

Because ISO 59001 is still under development, clause wording may change, but its direction is clear: it will follow the management system structure used by ISO 9001 and ISO 14001 while focusing on circular outcomes. In practical terms, businesses should expect the following types of requirements:

Define the scope of the circular economy management system: business units, product lines, locations and value-chain stages that are covered.

Establish a circular economy policy that sets direction on resource use, waste prevention, product lifetime, reuse and recovery ambitions.

Identify internal and external issues that affect circular performance such as market expectations, material risks, legislation on eco-design or take-back and technology trends.

Map interested parties and their needs, including customers, regulators, suppliers, waste partners and local communities.

Set measurable circular objectives and targets, for example on recycled content, repair rates, take-back volumes or landfill diversion, aligned with the policy.

Tip:Start by mapping material and product flows across your business. A simple diagram that traces inputs, production stages, distribution, use, return paths and end-of-life options often reveals where circular loops already exist and where new ones can be created.

How to prepare for ISO 59001 implementation?

Preparing for ISO 59001 is less about waiting for final text and more about building the management habits that any circular standard will expect. Many of the steps line up with common sense for resource-focused management. Refer to the points:

Run a gap analysis against the ISO 59000 family: compare your current approach to resource use, product design, waste management and reporting against the principles in ISO 59004, the business model ideas in ISO 59010 and the measurement guidance in ISO 59020.

Develop a circular economy baseline by collecting data on material use, waste streams, product returns, repair activities and secondary material flows.

Identify priority value chains or product lines where circular potential is high due to material costs, regulatory pressure, or customer interest.

Draft a circular economy policy and high-level objectives that senior management can endorse and communicate internally.

Build a cross-functional team that brings together design, procurement, production, logistics, finance, sustainability and quality so that circular decisions are not made in isolation.

Certification audit

Once ISO 59001 is published and certification schemes are in place, audits will likely follow the familiar pattern of other management system standards.

Stage 1 audit: Auditors review the documented circular economy management system: scope definition, policy, objectives, risk and opportunity planning, process descriptions, roles and competence.

Stage 2 audit: At Stage 2, auditors visit sites or review operational evidence to see how circular economy practices are applied.

Nonconformities: If auditors find gaps, such as missing controls for a key circular objective, weak monitoring of material flows or poor follow-up on targets, they raise nonconformities.

Management review: Management review pulls together performance information on circular objectives, indicators, incidents, external changes and improvement opportunities.

Final certification: After nonconformities are closed and the management system is shown to meet ISO 59001 requirements, a certificate is issued for the defined scope.

Surveillance audits: Surveillance visits, usually once a year, focus on whether the system still works as planned, whether targets are being monitored and whether new products, sites or partners keep circular objectives in view.

Recertification audits: Every three years or similar, a more extensive audit reviews the whole system, including any expanded scope, new circular solutions and lessons learned from earlier cycles.

What are the benefits of ISO 59001?

ISO 59001 can turn circular economy from a marketing slogan into a managed way of working. When the system is integrated into everyday decisions, businesses begin to see resource use, waste and product lifetimes as controllable levers rather than fixed conditions. Below are key benefits:

Better control over material and product flows, which can reduce waste and shrink raw material dependence.

Increased visibility of where value is lost in the lifecycle, opening paths for repair, refurbishment, remanufacturing or reuse services.

Improved resilience to price shocks or shortages in primary materials through greater use of secondary materials and design for multiple lifecycles.

Clearer targets and responsibilities for circular economy efforts, which makes it easier to coordinate design, operations, procurement and logistics.

Easier integration of circular work with quality and environmental management because the structure will align with ISO 9001 and ISO 14001.

Recent Trends

Circular economy is shifting from single-issue waste projects to a broader management topic that touches design, finance, logistics and digital technology. Businesses in manufacturing, electronics, construction, textiles and consumer goods are starting to build product passports, digital twins and material flow models so they can see where materials are at any point in time and how they might re-enter loops. At the same time, disclosure rules, eco-design laws, product stewardship schemes and climate-related reporting are pushing companies to show how product lifecycles affect emissions and resource use.

Many companies are now running circular initiatives alongside net-zero programs, linking energy use and material use in one view. Digital tools, including IoT sensors, blockchain-based traceability and advanced analytics, are being tried to track assets over longer lifetimes, manage reverse logistics and match secondary materials with new uses. Early movers are building internal “circular hubs” that coordinate design guidelines, supplier engagement, reverse logistics partners and measurement methods.

Training and courses

Pacific Certifications provide accredited training programs that can support organizations as ISO 59001 matures and circular management systems become certifiable:

Lead Auditor Training: For professionals who will assess circular economy management systems, review material and product flow controls, check objectives and indicators and evaluate how well the system is embedded.

Lead Implementer Training: For teams tasked with designing and rolling out a circular economy management system across product lines, sites and regions while aligning it with existing quality and environmental systems.

For training tailored to circular economy management in your business, contact [email protected].

How Pacific Certifications can help?

Pacific Certifications provides accredited audit and certification services for management system standards and is ready to support organizations that want to prepare for ISO 59001 once it is published. Our audits focus on how well your circular economy management system is defined, implemented and maintained across design, procurement, operations, logistics and end-of-life processes.

Contact Us

To discuss an audit plan around circular economy management or to prepare for future ISO 59001 certification, contact [email protected] or visit www.pacificcert.com.

Read more: Pacific Blogs