ISO 50001 and Energy Efficiency – Still Worth It Today?

Introduction

Energy has now become one of the boardroom issue as electric prices are rising, carbon regulations are tightening and customers across the globe are waiting to hear back from suppliers regarding their sustainability efforts with the use of energy. Since its publication, ISO 50001 has provided organizations with a systematic approach to have an objective way of measuring and improving energy performance across sites and fleets. ISO 50001 promises organizations with reduced energy consumption, reduced costs, and reduced emissions using a standardized management system. Now, one decade later, it is a fair question to ask: does ISO 50001 still have merit? For organizations where ISO 50001 lives as a system that links utility and metered data streams, offers defined responsibilities, and operates a commitment to continual improvement on energy performance, the answer is yes. The payback period is no longer just about energy bills; it is about accessing markets, completing the ESG template style reporting, or accomplishing net zero program requirements.

Book a quick readiness review with Pacific Certifications to see how your current practices map to ISO 50001 and where savings still hide.

Quick summary

ISO 50001 is an energy management system standard that embeds policy, metering, analysis, controls and review into one loop so institutions can improve energy performance over time. It aligns people, data and operations to reduce energy intensity and emissions while protecting reliability. When linked with real KPIs and site accountability, the standard continues to meet its original promise, lower cost per unit of output, more predictable consumption and better decision making for upgrades and procurement.

Why ISO 50001 still matters?

Energy risk touches finance, operations and reputation. ISO 50001 turns siloed initiatives into a single system—one policy, one set of objectives, one dashboard. It makes energy performance measurable at the line, building and portfolio levels and ties the results to management review and funding cycles. That discipline improves confidence for investors and buyers who now ask for credible energy and carbon data in tenders and supplier scorecards.

“ISO 50001 shifts energy from ad-hoc projects to a managed process where metering, maintenance and money work in one direction, lower consumption per unit of value.”

Table: ISO 50001 at a glance

What are the requirements for ISO 50001 certification?

A strong introduction helps align teams before you move to tasks. ISO 50001 requires a defined scope, a data-driven energy review and controls that hold gains in daily operation. Leadership must set policy and objectives, fund metering and projects and review results on a set cadence. Records, roles and methods bring consistency across shifts and sites. Below are the key requirements:

Establish scope and organizational boundaries for the energy management system.

Create an energy policy and measurable objectives linked to business goals.

Perform an energy review with baselines, significant energy uses and opportunity ranking.

Build an energy data plan covering meters, frequency and quality controls.

Define operational controls for setpoints, schedules and maintenance that affect energy.

Assign roles, competence needs and training for operators, engineers and buyers.

Plan projects with M&V methods, funding paths and persistence checks.

Monitor, analyse and report KPIs with thresholds and alert logic.

Run internal audits and management reviews on a fixed schedule.

Address nonconformities with root cause and time-bound corrective actions.

How to prepare for ISO 50001 certification?

Preparation blends diagnostics and quick wins. Start with metering coverage and a clean baseline, then align projects with a simple payback or IRR screen so savings are bankable and verified. Below are practical steps:

Complete a gap analysis against ISO 50001 and map current energy workflows.

Confirm meter hierarchy and data accuracy for the biggest loads first.

Build a ranked opportunity list with savings, cost and risk notes.

Standardize setpoints, schedules and shutdown procedures for major assets.

Train operators on exceptions and escalation rules tied to KPIs.

Pilot M&V on two or three measures to prove the pipeline approach.

Hold a management review to lock objectives, budgets and timelines.

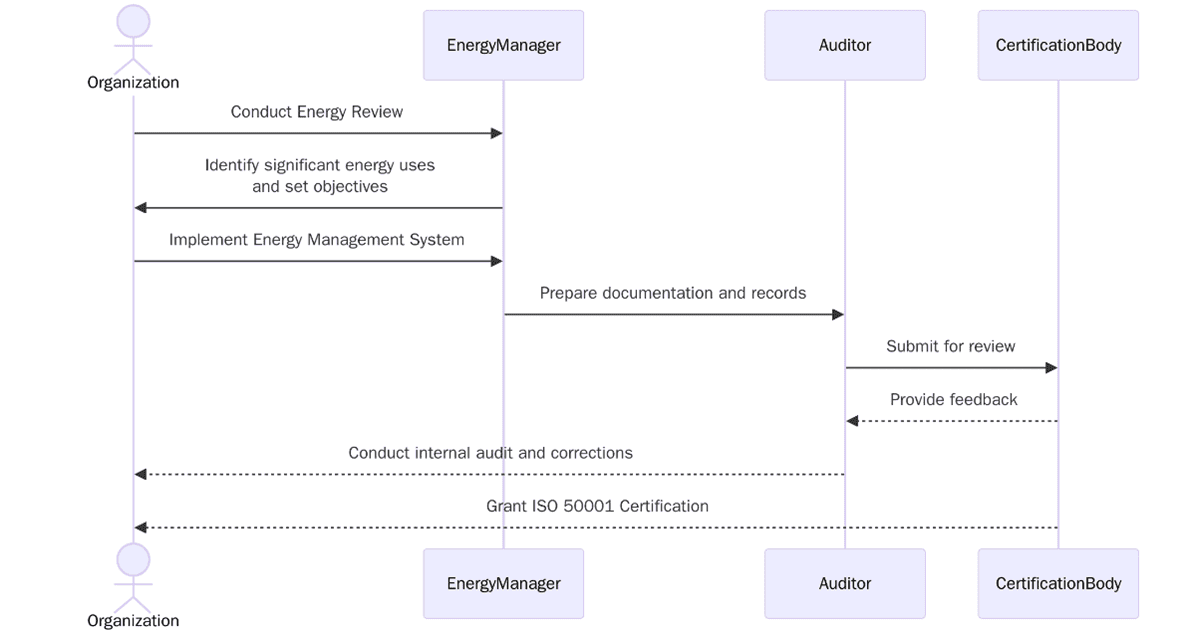

Certification audit

Stage 1 audit: Review scope, policy, energy review, baselines and documented methods.

Stage 2 audit: Verify implementation on the floor—controls, logs, dashboards and operator awareness.

Nonconformities: Correct with evidence of fix and persistence checks before approval.

Management review: Confirm objectives, resources and decision records support the system.

Final certification: Issued after successful closure of findings.

Surveillance audits: Annual checks confirm data quality and improvement activity.

Recertification audits: Every three years to confirm long-term performance.

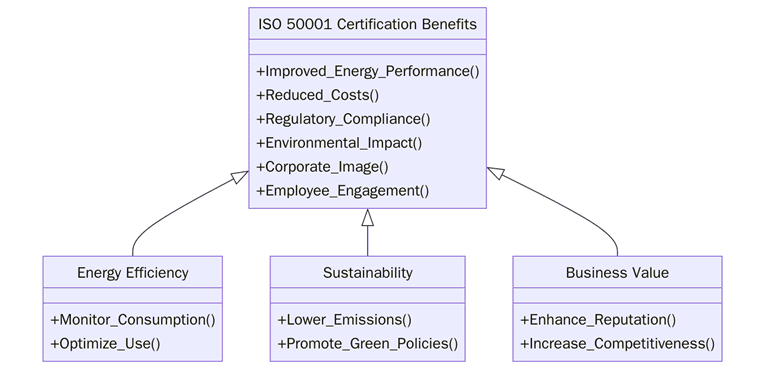

What are the benefits of ISO 50001 certification?

Energy programs fail without persistence. ISO 50001 keeps savings alive by combining metering, controls and roles inside one loop. The gains reach beyond bills to reliability and market credibility. Below are the key benefits:

Lower energy intensity and more predictable utility spend across seasons.

Verified savings using agreed M&V methods that finance can trust.

Faster project approval because objectives, baselines and KPIs are already defined.

Better uptime through maintenance tied to energy exceptions and equipment health.

Stronger procurement leverage via performance specs and whole-life cost criteria.

Clear governance with audit trails, review minutes and closure evidence.

Easier ESG reporting with traceable data and site-level KPIs.

Integration with ISO 9001, ISO 14001 and ISO 45001 under the same Annex SL structure.

KPIs that matter: kWh per unit, cost per unit, MTCO reduced, demand charge events avoided, audit closure days and measure persistence rate.

SLAs that hold the line: data availability, alarm response time and corrective action closeout.

Market Trends

Institutions are pairing ISO 50001 with submetering, building analytics and AI anomaly detection so exceptions trigger work orders within hours, not months. Power purchase choices now consider flexibility, not only price—on-site storage and demand response reduce peak events that inflate bills. Many buyers ask suppliers for energy intensity and reduction targets tied to contracts, so certified systems support sales and retention.

By 2030, expect deeper integration with carbon accounting and grid flexibility. ISO 50001-driven programs will link asset controls to market signals so loads shift without hurting output. Funding will keep moving to portfolio models—small measures bundled under shared M&V. Institutions that lock the basics now, metering, reviews, operator playbook, will pivot faster as tariffs, carbon prices and buyer rules tighten.

Training and courses

Pacific Certifications provides accredited training programs for ISO 50001 to build practical skills from the plant room to the boardroom:

· Lead Auditor Training: Audit planning, energy review evidence, data quality checks, nonconformity grading and reporting aligned with ISO 19011.

· Lead Implementer Training: Scoping, meter hierarchy design, baseline creation, opportunity ranking, M&V methods and persistence controls for long-term savings.

Contact [email protected] to schedule ISO 50001 training or awareness sessions for your teams.

How Pacific Certifications can help?

Pacific Certifications provides ISO 50001 certification and audit services for single sites and multi-site portfolios. Our independent assessments review policy, energy review, data plans, controls and improvement records. We issue Certificates of Conformity after impartial audits, no consultancy, so your results carry weight with customers and investors.

Contact Us

Request your ISO 50001 audit plan and site timeline. Write to [email protected] or visit www.pacificcert.com.

Read more: Pacific Blogs