ISO 45001: 5-Step Action Plan for Safety Management

Introduction

Safety excellence is not accidental. It is a result of clear policies, disciplined execution, accountability and constant review of workplace risks. ISO 45001 provides the framework to build a structured Occupational Health & Safety Management System (OHSMS), enabling institutions to reduce hazards, protect workers and build a dependable culture of safety. As regulatory scrutiny, employee expectations and contractor safety requirements expand, organizations in 2025 are turning to ISO 45001 not only for compliance but for operational reliability, workforce trust and long-term resilience.

Adopting ISO 45001 does not need to feel overwhelming. A focused, repeatable 5-step action plan helps teams move from intent to implementation, ensuring practical direction for leadership, supervisors and safety coordinators.

Discuss your OHS readiness approach with Pacific Certifications and plan your ISO 45001 audit journey confidently.

Quick summary

ISO 45001 outlines a structured method to identify hazards, evaluate risks, enforce safety controls and improve systems through internal audits and employee involvement. The 5-step plan simplifies implementation: define context, plan safety controls, deploy safeguards, monitor results and improve continuously. This cycle strengthens legal compliance, operational discipline and workforce confidence.

Why ISO 45001 matters today?

Modern workplaces handle more complexity than ever before, new technologies, contractor networks, remote teams and evolving regulatory expectations. ISO 45001 helps institutions formalize safety responsibilities, build prevention-focused systems and reduce incidents through structured monitoring and action. Certification strengthens tender eligibility, boosts employee morale and creates a traceable safety culture grounded in accountability and learning.

“ISO 45001 ensures that safety decisions are not reactive or event-driven, they are planned, measured and continuously refined based on evidence and worker engagement.”

Table: ISO 45001 – 5-Step Action Framework

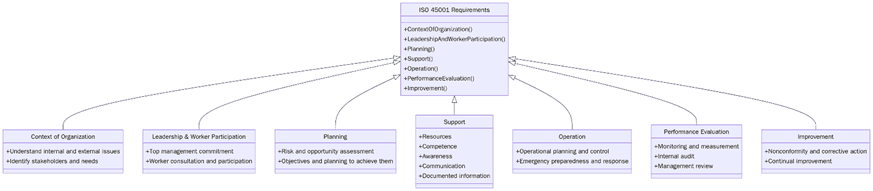

What are the requirements for ISO 45001 certification?

Before certification, institutions must develop a structured system that covers hazard control, legal compliance, employee participation and performance evaluation. The goal is consistent control of risks and documented improvement. Below are the key requirements:

Identify internal and external safety-related factors.

Define roles and responsibilities across all levels.

Establish an OH&S policy with measurable objectives.

Conduct risk assessments and determine safety controls.

Document emergency procedures and response plans.

Implement training and awareness programs for workers and contractors.

Maintain documented evidence such as inspections, training logs and incident reports.

Monitor performance using KPIs and internal audits.

Conduct management review meetings.

Implement corrective actions and maintain continual improvement.

Tip:Use leading indicators like near-miss reports and equipment audit frequency along with lagging indicators like injury rates for a balanced assessment.

How to prepare for ISO 45001?

Before certification, institutions should align people, documents and processes to the safety system. Preparation ensures clarity and accountability across teams.

Conduct a gap assessment and safety culture review.

Create or refine the OH&S policy and objectives.

Build a hazard register and PPE protocols.

Train supervisors and staff on safety responsibilities.

Establish emergency drills, reporting tools and communication channels.

Document contractor control and site supervision processes.

Perform internal audits and management review before the external audit.

Certification audit

Stage 1 audit: Review OH&S policy, documented procedures and readiness.

Stage 2 audit: Validate operational safety controls and worker involvement.

Nonconformities: Must be corrected with objective evidence.

Management review: Confirms leadership oversight and resource allocation.

Final certification: Issued after successful compliance verification.

Surveillance audits: Conducted yearly to maintain performance integrity.

Recertification audits: Every three years to renew certificate status.

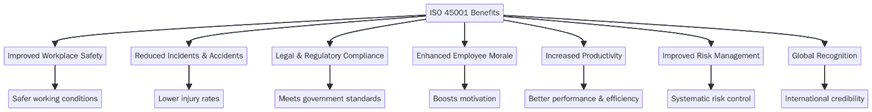

What are the benefits of ISO 45001?

ISO 45001 provides structured methods to protect workers, reduce accidents and improve compliance reliability. Institutions achieve stronger governance, improved incident prevention and enhanced operational trust. Below are the key benefits:

1. Lower workplace injury and incident rates through prevention-focused planning

2. Clear safety roles and accountability for supervisors and contractors

3. Higher employee morale and confidence in workplace safety practices

4. Stronger compliance with legal obligations and industry expectations

5. Improved emergency preparedness and drill performance

6. Better performance visibility through KPIs and structured reporting

7. Reduced downtime and disruption from accidents or equipment failures

8. Better insurance credibility and risk-management reputation

9. KPIs: lost-time injury frequency, near-miss capture rate, internal audit closure cycle

10. SLAs: hazard mitigation lead time, training completion window, corrective action closure targets

Discuss your OHS readiness approach with Pacific Certifications and plan your ISO 45001 audit journey confidently.

Market Trends

Safety management now includes psychosocial health, fatigue controls and digital reporting tools. Wearable monitoring devices, safety-mobile apps and AI-driven hazard prediction are gaining adoption. Contractor safety governance and remote work safety protocols are also priority areas.

Safety systems will increasingly rely on real-time monitoring, AI predictive alerts and digital audit trails. Organizations will incorporate mental wellbeing and ergonomic assessment tools into OHS dashboards. Remote workforce safety validation will continue expanding and automated reporting will support management review accuracy.

Training and courses

Pacific Certifications offers accredited programs to support ISO 45001 competency:

· Lead Auditor Training: For professionals conducting OH&S audits and reviewing system evidence.

· Lead Implementer Training: For individuals responsible for building and improving ISO 45001 systems, hazard controls and documentation.

Schedule training for your safety management team at [email protected].

How Pacific Certifications can help?

Pacific Certifications provides ISO 45001 certification and audit services, assessing workplace safety systems against global requirements. Our audits evaluate leadership commitment, workforce involvement, hazard controls, emergency preparedness and data-based improvement.

We issue Certificates of Conformity following impartial audits, ensuring recognition and integrity without providing consultancy or system design.

Contact Us

Request your ISO 45001 certification audit plan and surveillance cycle outline at [email protected] or visit www.pacificcert.com.

Read more: Pacific Blogs