ISO 14001 Implementation Guide: Step-by-Step Process for 2026 Certification

Introduction

ISO 14001 certification has moved from a nice-to-have credential to a core signal that an organization controls its environmental impact. Manufacturers, construction firms, logistics companies, energy operators and service providers are now asked in tenders and vendor portals how they manage emissions, waste, spills, noise and resource use, and whether their system aligns with ISO 14001.

A clear guide to ISO 14001 implementation helps you turn scattered procedures and “green” initiatives into one management system that links policy, risks, controls, data and improvement. If your organization wants to plan ISO 14001 certification in 2026, you can request a free ISO 14001 audit plan and cost estimate from Pacific Certifications to review scope, timelines, evidence expectations and integration with existing systems.

ISO 14001 Implementation Overview

ISO 14001 certification and implementation give organizations a structured way to control environmental impact across sites, projects, fleets and services. The standard asks you to define environmental policy, identify aspects and impacts, set objectives, control operations, monitor performance and correct issues. In practice, ISO 14001 implementation means joining environmental topics into one system rather than separate initiatives, so that audits, client questions and ESG disclosures can rely on the same verified data and records.

Benefits of ISO 14001 Certification for Organizations

Organizations in manufacturing, construction, logistics, energy, agriculture, real estate and services face rising pressure to explain how their operations affects air, water, soil, waste streams and resource use. Clients ask about emissions and waste in contracts, lenders want clarity for climate-risk assessments and communities expect visible control of spills, noise and local impact.

ISO 14001 certification for manufacturing, construction and logistics companies gives a clear answer to these questions. It shows that environmental topics are not handled as ad-hoc tasks, but planned through policy, risk-based thinking, documented controls, training, monitoring and management review. For example, a logistics operator can use ISO 14001 to control fuel use, noise, routing and yard operations, while a construction firm can focus on dust, noise, waste, spills and land disturbance.

Without ISO 14001, environmental controls often sit in separate procedures created to satisfy individual customers or local rules. That makes it hard to show one picture of environmental performance, and even harder to prove that controls are applied consistently. With ISO 14001, environmental planning, operations, monitoring and improvement follow one clear pattern that can be explained to auditors, clients and regulators.

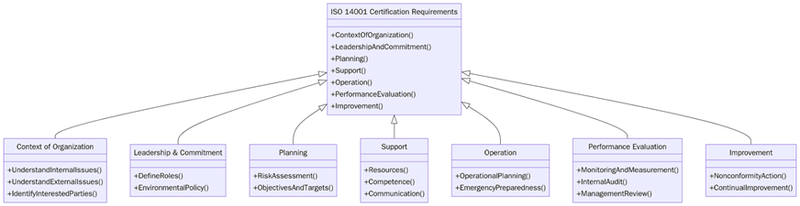

ISO 14001 Requirements: Complete Implementation Checklist

Before implementing ISO 14001, it helps to remember that it follows the same high-level structure as ISO 9001 and ISO 45001. The focus, however, is on environmental aspects, impacts, risks and controls. The system must cover how you plan, operate, check and improve environmental performance across your activities.

Below are some of the key ISO 14001 requirements that organizations must address:

Define the scope of the environmental management system, including sites, business units, processes, projects and activities that affect the environment.

Understand internal and external context, including environmental laws, permits, customer clauses, community concerns, climate-related risks and business goals linked to environment and ESG.

Identify interested parties such as regulators, neighbours, customers, lenders, insurers, employees and local communities, and understand their needs related to environmental performance.

Identify environmental aspects and impacts for your activities is a core requirement in ISO 14001 implementation, including emissions to air, discharges to water, waste, resource use, land use, biodiversity and noise.

Set an environmental policy that commits to pollution prevention, protection of the environment and meeting applicable legal and other requirements.

Monitor and measure environmental performance, maintain legal compliance registers, track incidents, near-misses, complaints and improvement actions.

Run internal audits and management reviews to check whether the system is working, where it needs changes and how it supports wider ESG and business goals.

ISO 14001 Implementation Preparation: 10-Step Readiness Guide

Preparing for ISO 14001 implementation means turning existing environmental practices into a system that is consistent, auditable and linked to clear objectives. Most organizations already do some environmental work: they measure fuel, manage waste contractors, respond to spills and track utility bills. ISO 14001 helps join these efforts into one framework. Below are some of the key preparation steps for ISO 14001 certification and implementation:

Map current environmental activities and controls at each site or project, including permits, inspections, waste contracts, spill responses, energy management and local reporting.

List existing environmental data, such as fuel use, electricity, water, waste volumes, emission factors, fines, complaints and incident records.

Align contractor and supplier controls with ISO 14001 expectations, for example waste management, transport, chemical suppliers, maintenance contractors and outsourced operations.

Prepare simple process-based documentation that describes how environmental controls are applied, rather than large manuals that staff find difficult to use.

Train supervisors and key staff on ISO 14001 clauses in plain language, focusing on how their daily decisions affect environmental performance and records.

Plan internal audits and a first management review before the certification body visits, so you can identify gaps and correct them early.

ISO 14001 Certification Audit Process: Stage 1, Stage 2 & Surveillance

Stage 1 audit – readiness review: The certification body reviews ISO 14001 scope, context, environmental policy, aspects and impacts register, legal and other requirements, objectives and targets, high-level operational controls, documentation, internal audit planning and management review approach.

Stage 2 audit – implementation verification: Auditors visit selected sites, depots, offices, plants or project locations to verify how environmental controls work in practice.

Nonconformities: Any nonconformities raised during Stage 1 or Stage 2 must be corrected through root-cause analysis, updated procedures or controls, improved records and evidence that new practices are in use.

Management review: Leadership must periodically review environmental performance, including objectives, KPIs, legal compliance, incidents, resource needs, risks, opportunities and improvement actions. A clear management review shows that ISO 14001 implementation is not just a technical project but part of overall business control.

Surveillance audits and recertification: After certification, surveillance audits are carried out annually to check that ISO 14001 processes remain active and effective as products, projects and locations change. Recertification every three years involves a broader review of the system, including trends in performance, new environmental risks, changes in law and developments in ESG reporting.

Key Benefits of ISO 14001 Certification: Cost Savings & Compliance

ISO 14001 certification and implementation are most valuable when they support clear decisions, measurable improvements and better communication with clients, regulators and communities. Instead of treating environmental topics as separate tasks, the organization gains one system for planning, controls, data and improvement. Below are some of the key benefits:

Better control of environmental risks and costs, as high-impact activities are identified, planned and monitored instead of managed informally.

ISO 14001 can reduce operational costs through improved resource efficiency, energy savings and waste reduction across sites, fleets and projects.

Stronger position in tenders and vendor-approval processes where customers ask for environmental management evidence or ISO 14001 certification.

Clearer internal responsibilities for environmental topics, so that management, supervisors and staff know their role in ISO 14001 implementation.

Easier integration with ISO 9001 and ISO 45001, giving a joined view of quality, environment and health and safety for plants, projects and service operations.

ISO 14001 Implementation Cost & Timeline

Cost and timeline for ISO 14001 implementation depend on how complex your operations are and how much environmental control you already have in place. Rather than a fixed fee, the investment usually reflects size, risk and scope.

Key cost factors include organization size and employee count, the number of sites in scope, current environmental management maturity, integration with existing systems such as ISO 9001 or ISO 45001 and certification body fees. Some organizations also choose to use external consultants, which adds to cost but can shorten the learning curve if internal resources are limited.

Typical timeline expectations are more predictable. A focused gap analysis and planning phase often takes 2–4 weeks. System design and implementation, including procedures, training and control rollouts, usually takes 3–6 months depending on the number of sites and activities. Internal audits and preparation for certification add another 4–6 weeks. Certification audits themselves are normally scheduled and completed within 1–2 months, depending on the availability of auditors and your preferred dates.

ISO 14001 Certification Trends 2026: ESG Integration & Climate Risk

Looking toward 2026, more buyers, lenders and regulators are linking ISO 14001 with climate-risk management, ESG ratings and supply-chain screening. Manufacturing and construction firms are asked not just whether they have ISO 14001, but how it supports net-zero targets, waste reduction and supplier control. Logistics operators are pushed to explain fuel use, routing and yard operations, while energy-intensive industries face more questions on emissions and resource use.

Organizations are also using ISO 14001 data for broader ESG reporting, joining environmental KPIs with quality, safety and information-security data. Many choose to integrate ISO 14001 with ISO 9001 and ISO 45001 so that one management system supports customer, environmental and safety commitments. Companies that invest in ISO 14001 certification and implementation now will find it easier to respond to tenders, ESG questionnaires, investor reviews and lender climate-risk questions in 2026 and beyond.

ISO 14001 Training Courses: Lead Auditor & Lead Implementer Programs

Pacific Certifications provides accredited ISO 14001 training courses to support implementation in manufacturing, construction, logistics, energy, services and public-sector organizations. If your organization is looking for ISO 14001 training that covers practical implementation, clause understanding and audit readiness, our team is equipped to help you.

ISO 14001 Lead auditor training supports professionals who need to evaluate environmental management systems, including aspects and impacts analysis, legal compliance evaluation, operational controls, monitoring and improvement records.

ISO 14001 Lead implementer training supports teams that are building or upgrading environmental management systems to meet certification needs. It covers system design, aspects and impacts methodology, objective setting, control planning, documentation structures and preparation for the ISO 14001 certification audit.

Get ABIS-Accredited ISO 14001 Certification with Pacific Certifications

Pacific Certifications provides ABIS-accredited ISO 14001 certification and audit services for manufacturing, construction, logistics, and energy sectors as well as other industries and service organizations. We assess scope, environmental aspects and impacts, legal and other requirements, objectives and targets, operational controls, monitoring and measurement, internal audits and management reviews. We also support ISO 14001 integration with ISO 9001 and ISO 45001 where organizations want one joined management system for quality, environment and health and safety. We issue Certificates of Conformity following impartial audits and do not provide consultancy or system design services.

Contact Us

To request an ISO 14001 audit plan and certification quote, or discuss ISO 14001 integration with your existing systems, contact [email protected] or visit www.pacificcert.com.

Read more: Pacific Blogs