Energy Management Systems Explained: The Plan, Do, Check, Act Cycle

Introduction

Energy is no longer just a cost, it’s a measurable indicator of performance, sustainability and competitiveness. As industries transition toward low-carbon operations, managing energy use systematically has become vital. The Plan-Do-Check-Act (PDCA) model, which underpins ISO 50001, provides a clear roadmap for organizations to improve their energy performance in a structured and verifiable way. It converts energy savings from isolated projects into a continuous improvement cycle where every action is measured, reviewed and refined.

Start an ISO 50001 readiness discussion with Pacific Certifications to assess how the PDCA cycle can strengthen your energy management practices.

Quick summary

The PDCA cycle ensures that energy management is not a one-time initiative but an ongoing process. It helps organizations plan improvements, implement controls, monitor performance and adjust based on results. ISO 50001 builds this model into every clause, linking leadership commitment, energy policy, objectives, data analysis and performance evaluation under one management system. When applied consistently, PDCA reduces energy consumption, stabilizes costs and improves carbon performance.

Why the PDCA model matter in energy management?

Many organizations struggle to maintain energy efficiency beyond the initial savings phase. The PDCA approach prevents backsliding by creating a repeatable loop of planning, execution, evaluation and refinement. It embeds accountability and makes energy management part of day-to-day decisions rather than an occasional initiative.

This structure allows energy teams to work in sync with finance, operations and maintenance while aligning with broader ESG and carbon-reduction goals.

PDCA transforms energy efficiency from a project-based effort into a culture of measurable improvement, built on data and leadership accountability.

ISO 50001 Clauses Aligned with the PDCA Cycle

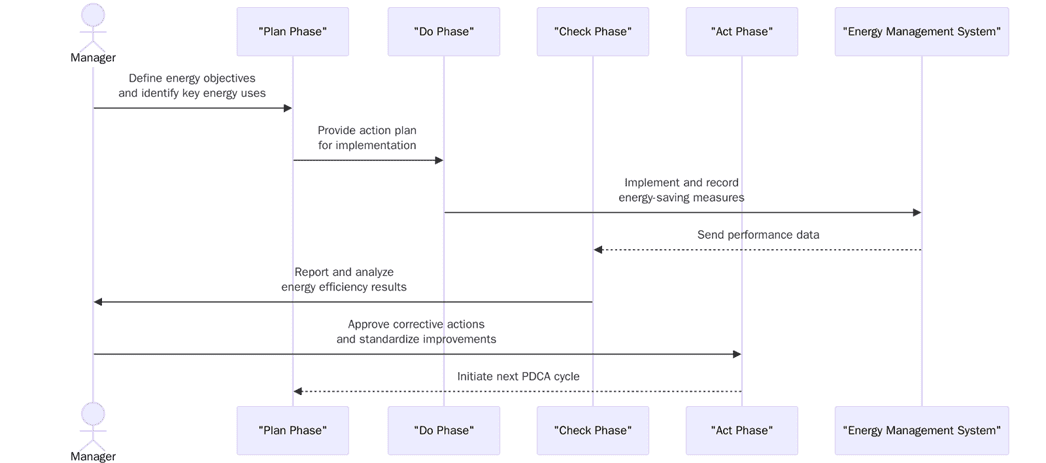

Plan - Building the foundation

The planning phase sets direction. It begins with understanding the context of the organization and the energy-related factors that influence performance. Leadership must establish an energy policy, define measurable objectives and identify significant energy uses (SEUs). Baselines are created to compare current consumption with improvement targets.

Key activities include:

Define the scope and boundaries of the energy management system.

Identify major energy-consuming assets and systems.

Establish measurable energy objectives and KPIs.

Conduct an energy review and create an action plan.

Allocate resources and responsibilities for energy performance.

Do - Implementing the plan

The Do phase focuses on executing the energy management strategy. This includes developing operational controls, training staff and ensuring systems are maintained for optimal performance. Communication and awareness play a critical role, as every employee influence energy use.

Key actions include:

Implement operational controls for SEUs.

Conduct regular equipment maintenance and calibration.

Train operators on efficient equipment use and data collection.

Integrate energy efficiency into procurement and design decisions.

Establish procedures for emergency energy situations.

Check - Measuring and evaluating performance

The Check phase validates whether energy performance objectives are being met. Data analysis, internal audits and management reviews help identify gaps and opportunities for improvement.

Key actions include:

Measure and monitor energy consumption at asset and process levels.

Verify data accuracy through calibration and validation processes.

Conduct internal audits and analyse deviations from baselines.

Evaluate the effectiveness of implemented controls.

Report findings to management for review.

Act - Improving and sustaining performance

The Act phase closes the loop by addressing nonconformities, implementing corrective actions and ensuring that lessons learned inform future planning. This is where continuous improvement takes hold—transforming data insights into long-term energy gains.

Key actions include:

Review audit results and identify recurring nonconformities.

Implement corrective and preventive actions with deadlines.

Update objectives, policies and procedures based on findings.

Communicate results to staff and recognize achievements.

Feed outcomes into the next PDCA cycle for renewed action.

Common SLAs include corrective action closure within 30 days and quarterly management reviews.

What are the benefits of applying PDCA in energy management?

A structured PDCA approach helps organizations embed discipline into energy management and build lasting savings. Below are the major benefits:

1. Consistent improvement in energy efficiency and cost reduction

2. Reliable data-driven decisions based on verified performance metrics

3. Stronger cross-departmental communication and ownership of energy results

4. Better control of operating costs and reduced carbon footprint

5. Improved alignment with ISO 9001, ISO 14001 and sustainability reporting

6. Greater transparency for investors and regulators through measurable KPIs

7. Reduced downtime due to proactive maintenance and monitoring

8. Enhanced employee awareness and accountability in energy practices

9. Clear SLAs for data integrity, monitoring frequency and audit closures

Market Trends

In recent years, organizations are integrating real-time energy analytics, IoT sensors and AI-driven forecasting into their PDCA cycles. Energy dashboards automate the “Check” and “Act” phases, providing predictive alerts for unusual consumption patterns. Companies are also linking ISO 50001 systems with carbon accounting platforms to meet Scope 1 and Scope 2 reporting requirements.

By 2030, the PDCA cycle will evolve through continuous digital feedback loop where AI and automation drive improvement autonomously. Smart grids, blockchain-based energy tracking and digital twins will help institutions predict consumption and reduce waste before it occurs. Organizations that embed PDCA in both operations and design will lead in resilience, cost control and compliance with carbon neutrality goals.

Training and courses

Pacific Certifications provides accredited training programs for ISO 50001 and PDCA-based energy management systems:

Lead Auditor Training: Focuses on planning and conducting energy audits, reviewing data accuracy and verifying performance against ISO 50001 clauses.

Lead Implementer Training: Guides professionals through building and operating an energy management system aligned with the PDCA model, covering baselines, SEUs, KPIs and continual improvement methods.

For enrolment or customized training programs, contact [email protected].

How Pacific Certifications can help?

Pacific Certifications provides ISO 50001 certification and audit services that assess the effectiveness of your energy management system and PDCA implementation. Our audits evaluate baselines, objectives and monitoring controls to verify continual improvement.

We issue Certificates of Conformity after impartial audits, helping organizations validate their energy and sustainability commitments globally.

Request your ISO 50001 certification audit plan at [email protected] or visit www.pacificcert.com.

ContactUs

If you need support with ISO certification in Maldives, contact us at [email protected].

Author: Alina Ansari

Read More at: Blogs by Pacific Certifications