Benefits of Integrating ISO 45001 with ISO 9001

Introduction

Organizations today are recognizing that safety and quality are not separate objectives, they are two sides of operational excellence. When combined, ISO 45001 (Occupational Health & Safety Management System) and ISO 9001 (Quality Management System) create a unified approach that strengthens leadership, reduces risks and builds long-term sustainability.

Integrating these two systems helps institutions avoid duplicated work, align policies and create a single management framework that drives both employee safety and customer satisfaction. In recent years, industries across manufacturing, logistics and energy are increasingly adopting integrated management systems (IMS) to manage compliance, efficiency and people well-being together.

Talk to Pacific Certifications to understand how integrated ISO 45001 and ISO 9001 certification audits can streamline safety and quality management for your organization.

Quick summary

An integrated approach to ISO 45001 and ISO 9001 brings multiple organizational systems: safety, quality, documentation and process control under one structure. This alignment improves governance, resource use and decision-making while maintaining compliance with international standards. Integration also supports consistent internal audits, unified risk assessments and shared performance indicators.

Why integrating ISO 45001 and ISO 9001 matters?

Modern organizations face rising expectations, from employees seeking safe workplaces to customers demanding consistent quality. Maintaining two separate systems for quality and safety often leads to overlaps, inconsistent data and wasted effort.

This alignment ensures that leadership, process owners and auditors follow a single structure of Plan-Do-Check-Act (PDCA), reducing duplication while improving accountability and transparency.

“Integrating ISO 9001 and ISO 45001 creates one cohesive management culture, where safety defines performance and quality drives trust.”

Table: ISO 9001 + ISO 45001 Integration Overview

What are the requirements for integration?

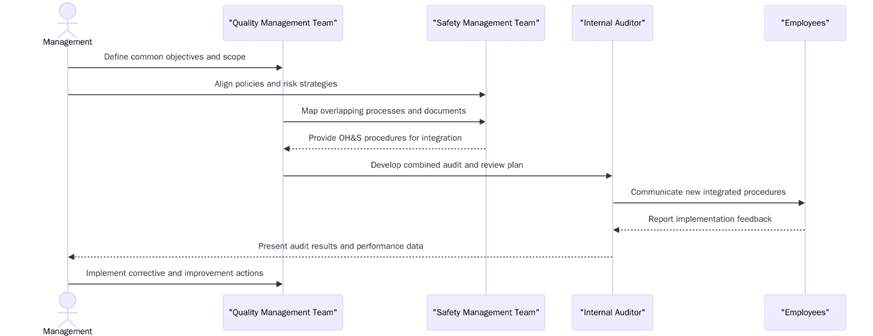

Integrating ISO 45001 and ISO 9001 requires aligning processes, leadership involvement and documentation under a unified framework. Below are the key steps to achieve successful integration:

1. Establish an integrated policy that covers both quality and safety.

2. Conduct a joint context and stakeholder analysis.

3. Define shared objectives and KPIs for safety and quality.

4. Combine risk assessments covering both product defects and workplace hazards.

5. Standardize document and record control systems.

6. Conduct joint training for employees and managers.

7. Integrate internal audit and management review cycles.

8. Harmonize incident and nonconformity reporting methods.

9. Update process owners’ roles to include safety and quality accountability.

10. Implement continual improvement measures under one PDCA cycle.

Tip:Maintain a unified risk register with entries for both operational safety and quality risks to improve transparency during audits.

What are the benefits of integrating ISO 45001 with ISO 9001?

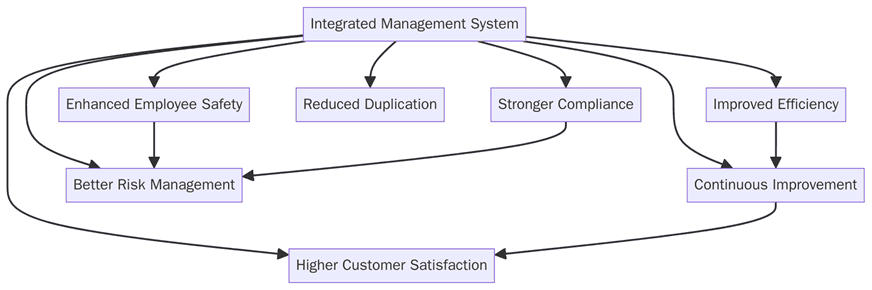

Integrating these systems strengthens both quality and safety outcomes while improving the organization’s overall performance. Below are the major benefits:

1. Simplified documentation and reduced duplication of policies and audits

2. Clearer leadership structure and resource management across departments

3. Improved employee awareness by linking product quality with workplace safety

4. Reduced audit time and certification costs through shared audits and evidence

5. Streamlined management reviews with unified objectives and reporting metrics

6. Stronger data-based decisions supported by shared KPIs and internal audits

7. Enhanced stakeholder trust through integrated governance and accountability

8. Increased consistency in operations, reducing both safety incidents and quality defects

9. KPIs: incident frequency rate, product rejection rate, internal audit closure cycle, customer satisfaction index

10. SLAs: corrective action closure within 30 days, supplier audit completion time, employee training refresh cycle

Market Trends

Organizations are adopting integrated management systems to simplify compliance audits and ESG reporting. Integrated digital dashboards are being used to track both safety and quality performance in real time. Companies in automotive, healthcare and construction are using joint ISO 45001-9001 frameworks to meet global buyer requirements and supplier audits efficiently.

By 2030, more certifications will be issued as integrated audits rather than separate standards. Artificial intelligence and automation will merge safety metrics, customer complaints and quality data into unified dashboards. Institutions that integrate early will save audit costs, improve data visibility and gain faster access to supplier approvals and government contracts.

Training and courses

Pacific Certifications offers accredited training for professionals aiming to manage integrated systems for ISO 9001 and ISO 45001:

· Lead Auditor Training: For those conducting integrated audits covering both quality and safety requirements.

· Lead Implementer Training: For personnel responsible for merging ISO 9001 and ISO 45001 systems into one structure.

To schedule an integrated management training program, contact [email protected].

How Pacific Certifications can help?

Pacific Certifications provides accredited integrated certification audits for ISO 9001 and ISO 45001. Our team assesses quality, safety and leadership systems under a unified framework to help institutions maintain compliance and measurable performance improvement.

We issue Certificates of Conformity following impartial integrated audits and ensure that organizations meet both quality and safety expectations consistently.

Request your integrated ISO audit plan and certification roadmap at [email protected] or visit www.pacificcert.com.

Contact Us

If you need support with ISO certification, contact us at [email protected].

Read More at: Blogs by Pacific Certifications