Analysing the Costs & Potential ROI of ISO 9001 Certification

Introduction

Organizations across every industry, from manufacturing and logistics to healthcare and education, rely on ISO 9001 certification to prove that their quality management practices meet global standards. But one question often stands out: Is ISO 9001 worth the investment? The costs of certification are visible, but the returns, improved efficiency, customer trust and market access, extend far beyond paperwork. In recent years, ISO 9001 continues to serve as a value-creating system that directly influences profitability, competitiveness and long-term resilience.

Request a detailed ISO 9001 audit plan from Pacific Certifications to understand certification costs, audit scope and the ROI potential for your organization.

Quick summary

ISO 9001:2015 defines the requirements for a Quality Management System (QMS) that enables organizations to consistently deliver products and services that meet customer and regulatory needs. The cost of ISO 9001 certification varies depending on size, complexity, locations and process maturity. While the investment includes audits, training and implementation time, the financial and operational returns, such as reduced waste, improved customer satisfaction and higher retention, make it a measurable, long-term gain.

Why ISO 9001 certification matters?

In a competitive, data-driven market, ISO 9001 certification offers more than compliance, it serves as a universal proof of quality and operational control. It opens access to new contracts, reduces operational inefficiencies and increases accountability across departments.

Global buyers and government tenders increasingly require ISO 9001 certification as part of supplier qualification. Beyond contracts, it builds a culture of continual improvement and risk-based thinking where data and accountability drive decisions.

“ISO 9001 certification is not an expense; it’s a performance multiplier that strengthens quality, efficiency and customer loyalty.”

Table: ISO 9001 Certification Cost and ROI Overview

What are the requirements for ISO 9001 certification?

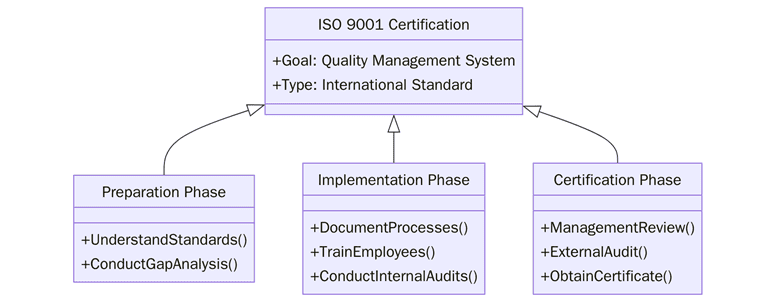

To earn ISO 9001 certification, an organization must demonstrate control over its processes and a structured system for continuous improvement. The requirements include leadership involvement, documented procedures, performance measurement and customer focus. Below are the key steps:

Define the scope of your QMS, including applicable products and services.

Establish a quality policy and measurable objectives aligned with business goals.

Identify internal and external issues affecting quality performance.

Define roles, responsibilities and process ownership.

Develop documented procedures for operations, customer communication and control of nonconforming outputs.

Conduct internal audits and management reviews.

Implement risk-based thinking in decision-making.

Evaluate supplier performance and process efficiency.

Record and track customer satisfaction and feedback trends.

Take corrective actions to address nonconformities and drive improvement.

Tip:Track KPIs like customer complaint closure time, defect rate, supplier audit scores and internal audit closure time to evaluate QMS performance.

How to prepare for ISO 9001 certification?

Proper preparation minimizes certification costs and shortens the audit cycle. Institutions that conduct internal audits, clean documentation and engage leadership early typically experience smoother certification.

Conduct a gap analysis against ISO 9001 requirements.

Develop or update the quality manual and procedures.

Train employees on QMS principles and responsibilities.

Review customer feedback and performance metrics.

Implement risk assessment tools to prioritize improvements.

Carry out internal audits and corrective actions.

Schedule a management review meeting before Stage 1.

Certification audit

Stage 1 audit: Reviews the organization’s documentation, policies and preparedness.

Stage 2 audit: Evaluates practical implementation, process control and evidence of compliance.

Nonconformities: Must be corrected and documented before certification approval.

Management review: Confirms leadership oversight and performance tracking.

Final certification: Issued after successful verification of system compliance.

Surveillance audits: Conducted annually to ensure ongoing conformity.

Recertification audits: Every three years to maintain certification validity.

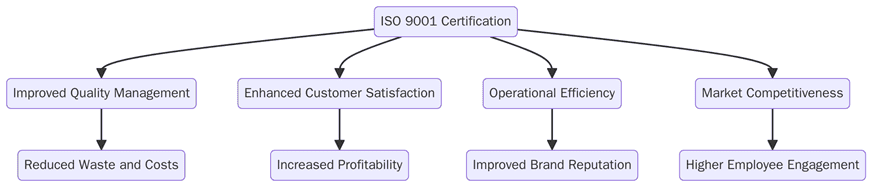

What are the benefits and ROI of ISO 9001 certification?

Before measuring ROI, it’s important to view benefits as both financial and operational. While certification brings tangible gains like reduced waste and rework, it also delivers intangible value through customer satisfaction and stronger brand reputation. Below are the key benefits:

Improved process control and reduced production errors, lowering costs by 10–20%

Shorter lead times and faster delivery performance through streamlined workflows

Increased customer satisfaction scores and repeat business opportunities

Better supplier quality control and reduced rejections

Stronger data-driven decision making through defined KPIs and internal audits

Access to high-value contracts that require ISO 9001 certification

Improved staff engagement and accountability across departments

Greater consistency in product and service delivery, reducing warranty claims

KPIs: defect rate reduction %, customer complaint resolution time, audit closure days, on-time delivery ratio

SLAs: corrective action closure within 30 days, supplier audit completion rates, feedback response turnaround

Organizations often see payback within 12–24 months of certification. For instance, manufacturers typically save between 5–10% of operating costs annually through reduced waste and service organizations improve customer retention by up to 15% within a year of certification.

Recent Trends

In recent years, ISO 9001 certification has become a central element in ESG and sustainability reporting, linking quality performance with environmental and social outcomes. Automation in QMS monitoring, data analytics and supplier evaluation is reducing manual effort. Businesses are also using integrated management systems, combining ISO 9001, ISO 14001 and ISO 45001, to cut audit costs and unify reporting.

By 2030, ISO 9001 will evolve toward digital quality ecosystems with real-time process control and predictive analytics. Certification will increasingly rely on data integration from IoT devices, CRM systems and supply chain dashboards. Institutions that automate quality tracking and link performance to customer behaviour analytics will achieve faster ROI and maintain a competitive edge.

Training and courses

Pacific Certifications provides accredited training programs for ISO 9001 to help organizations strengthen quality and compliance capability:

· Lead Auditor Training: For professionals conducting QMS audits, evaluating process effectiveness and identifying nonconformities.

· Lead Implementer Training: For managers building or upgrading ISO 9001 systems to align with business objectives and customer needs.

To schedule ISO 9001 training or awareness sessions, contact [email protected].

How Pacific Certifications can help?

Pacific Certifications provides ISO 9001 certification and audit services for organizations across all sectors. Our independent assessments evaluate leadership commitment, process control, performance tracking and continual improvement systems.

We issue Certificates of Conformity after impartial audits, ensuring transparency, accountability and global recognition. Request your ISO 9001 audit plan and cost breakdown at [email protected] or visit www.pacificcert.com.

Contact Us

If you need support with ISO certification with ISO 9001 Certification, contact us at [email protected].

Read More at: Blogs by Pacific Certifications